An energy-saving drum type grain and oil frying machine

A kind of seed frying machine and drum-type technology, which is applied in the direction of oil/fat production, fat production, food processing, etc. It can solve the problems of affecting the quality of oil, burnt materials, large heat loss, etc., so that it is not easy to burnt and heated evenly , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

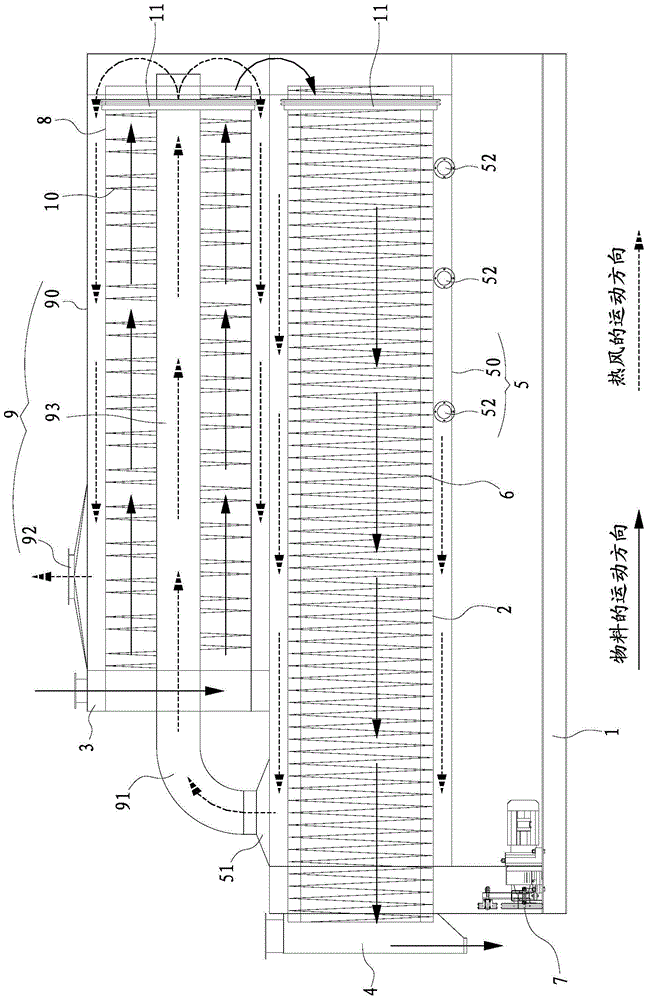

[0027] see figure 1 According to the energy-saving drum type grain and oil frying machine of the present embodiment, it includes a frame 1; a frying drum 2; a feeding device 3 and a discharging device 4; The heating device 5 for heating; the stir-frying blade 6 extending along the length direction of the fried seed drum 2 and arranged inside the fried seed drum 2; the driving device 7 for driving the fried seed drum 2 to rotate; The heating drum 8; the heating device 9 located on the outer periphery of the heating drum 8 for preheating the heating drum 8; the spiral blade 10 extending along the length direction of the heating drum 8 and arranged inside the heating drum 8; and the fried seed drum 2 The transmission device 11 of the transmission connection.

[0028] Specifically, the fried seed drum 2 is erected horizontally on the frame 1, and the feeding device 3 and the discharging device 4 communicate with the feeding end and the discharging end of the fried seed drum 2, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com