Zinc sheet cast ingot collecting device

A collection device and ingot casting technology, applied in forging/pressing/hammering devices, manufacturing tools, forging/pressing/hammering machines, etc., can solve problems such as poor stability, hidden dangers to worker safety, pollution, etc., and achieve savings Synergistic operation time, ensure stable production, ensure the effect of softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

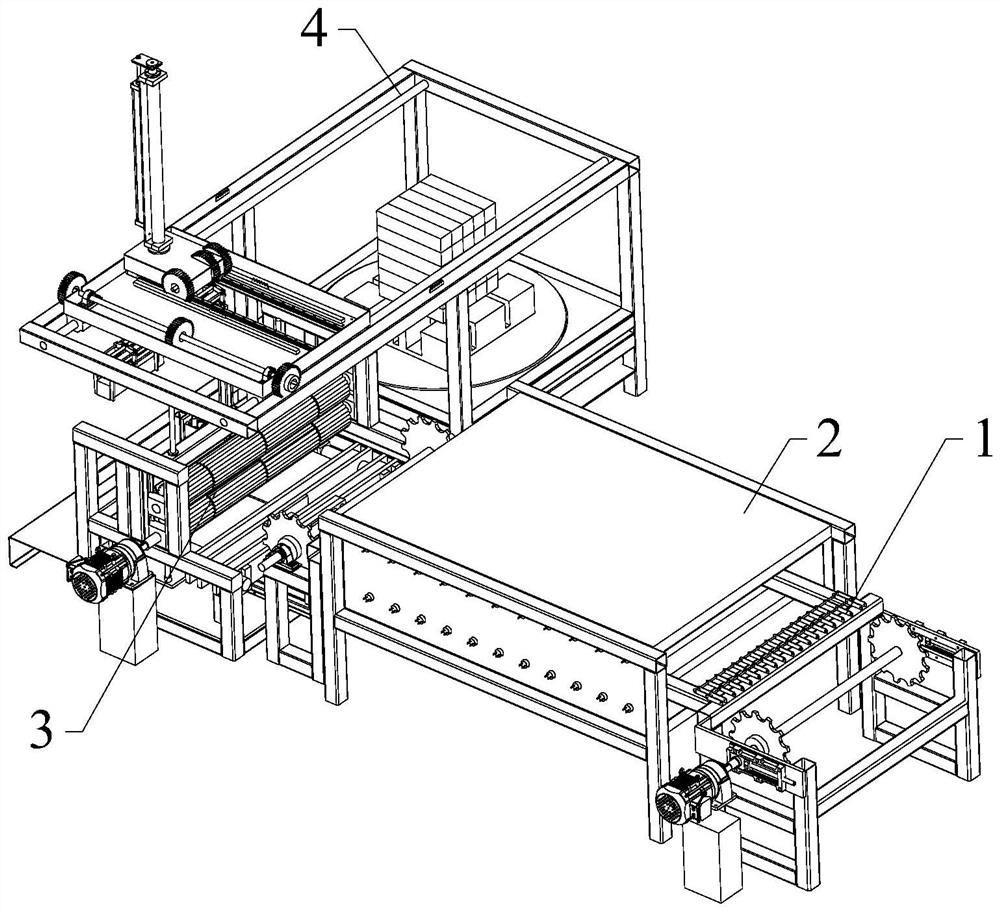

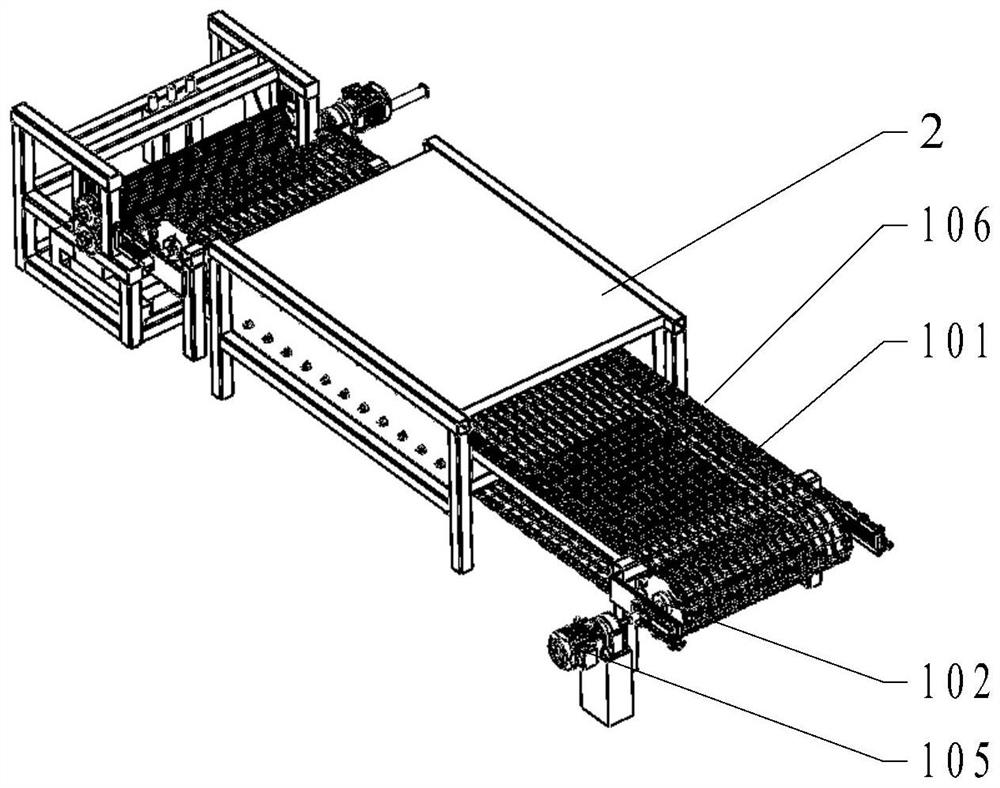

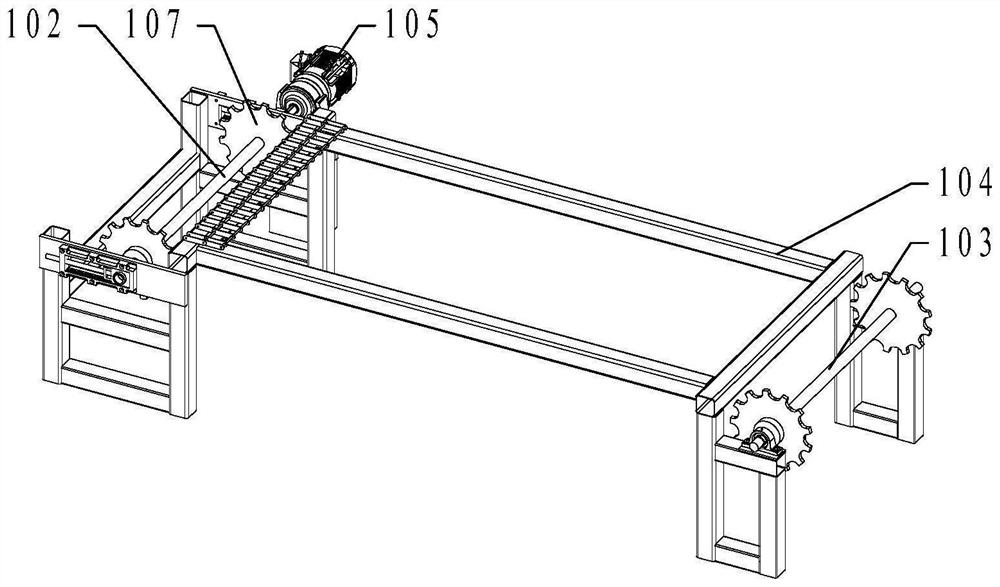

[0057] see Figures 1 to 12 , as shown in the figure, the present invention provides a zinc flake ingot collecting device, including a conveying mechanism 1, a softening mechanism 2, an ingot casting mechanism 3 and a collecting mechanism 4; the conveying mechanism 1 is connected to the ingot casting mechanism 3 through the softening mechanism 2 , the collecting mechanism 4 is arranged on one side of the ingot casting mechanism 3, and the electrolyzed zinc flakes are transported to the ingot casting mechanism 3 through the conveying mechanism 1, and are softened by the softening mechanism 2 during the conveying process, which is convenient for subsequent ingot forming, and the collecting mechanism 4. It is convenient to collect and transport the products formed by the ingot, and improve the production efficiency.

[0058] The softening mechanism 2 includes a softening frame 201, a softening chamber shell 202, and an electric heating pipe 203. The softening chamber shell 202 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com