Patents

Literature

38results about How to "Easy to collect and transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

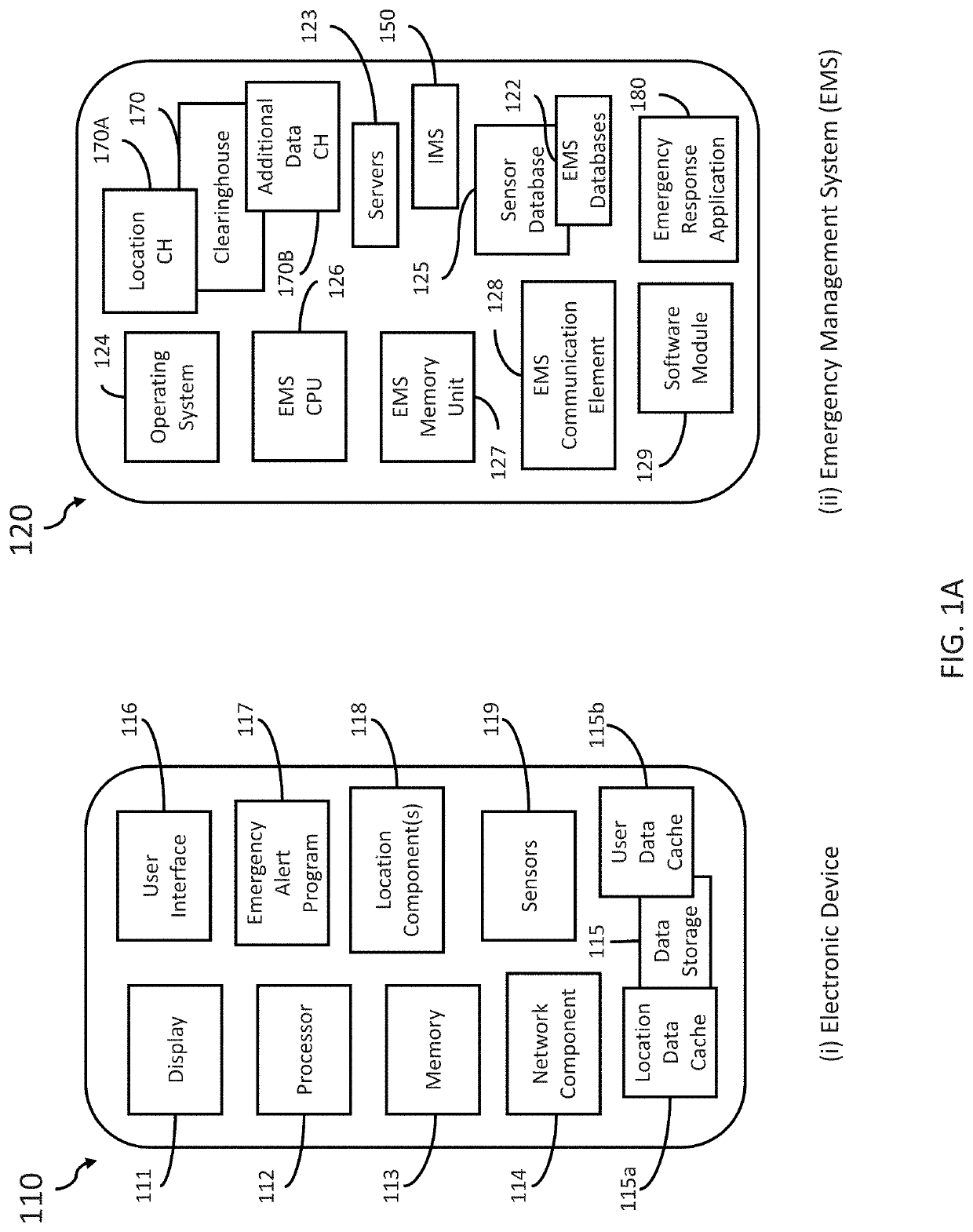

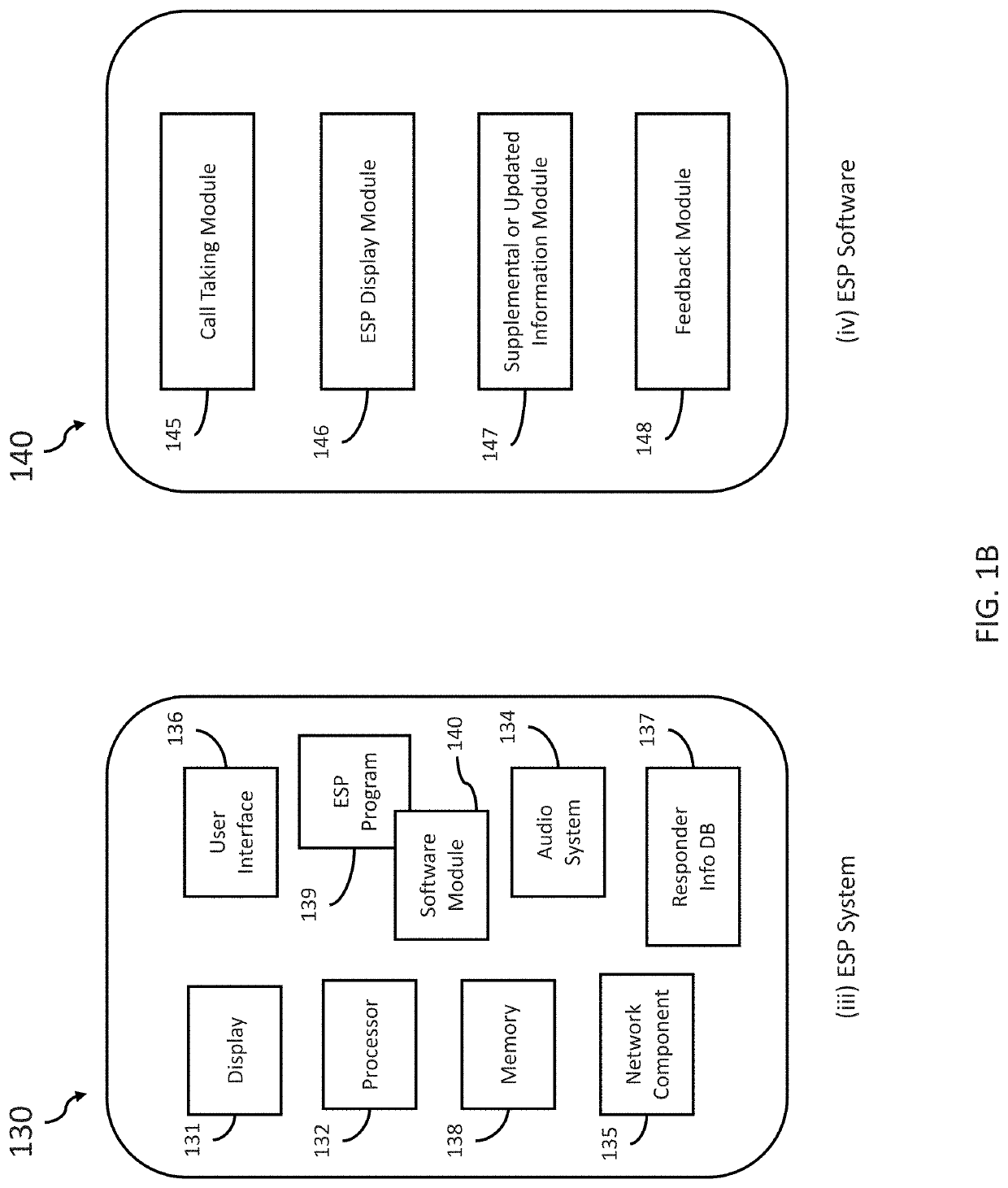

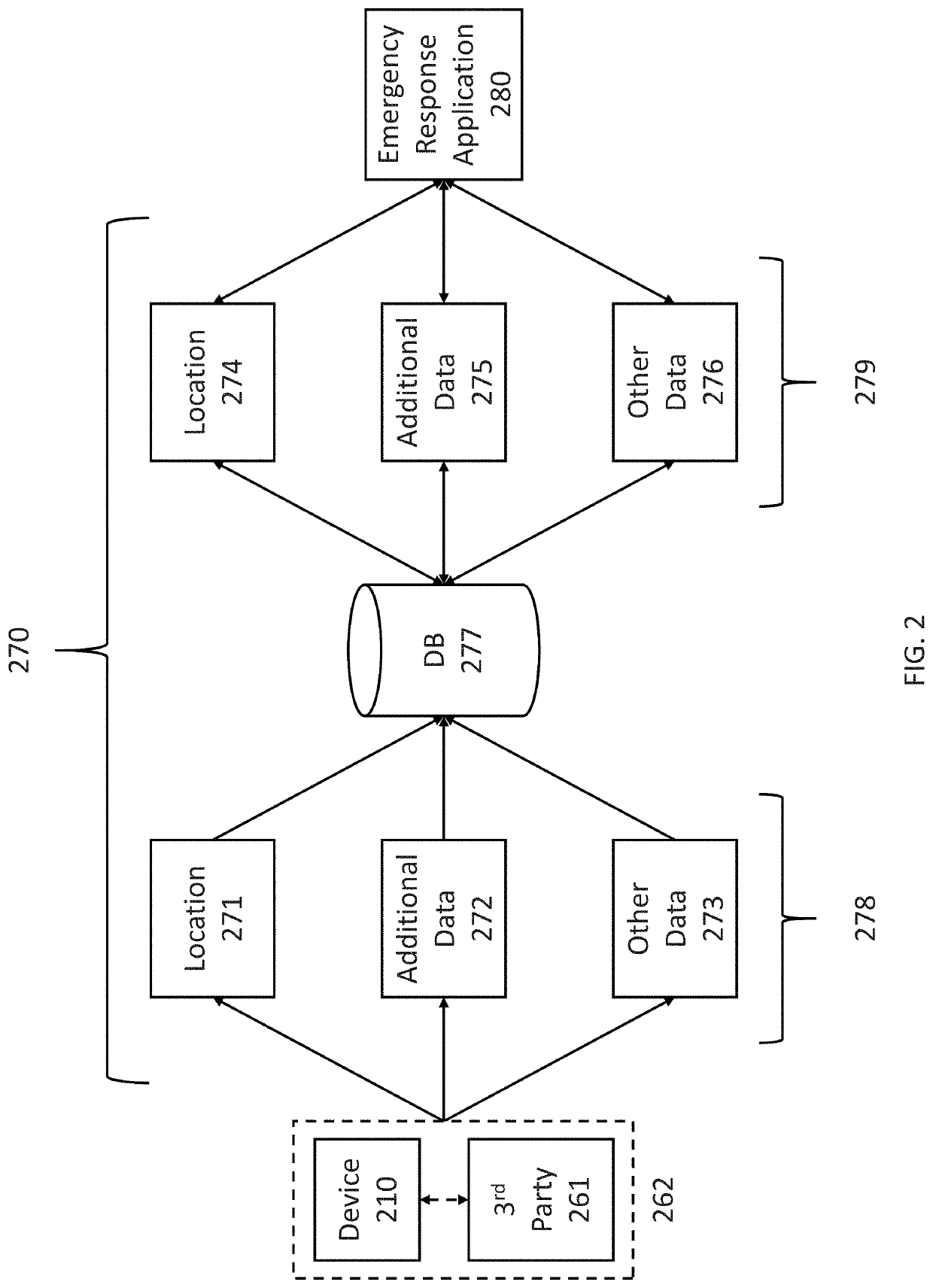

Systems & methods for intelligently managing multimedia for emergency response

PendingUS20200059776A1Increase the number ofHigh popularityDigital data information retrievalInterconnection arrangementsMediaFLOEmergency encounter

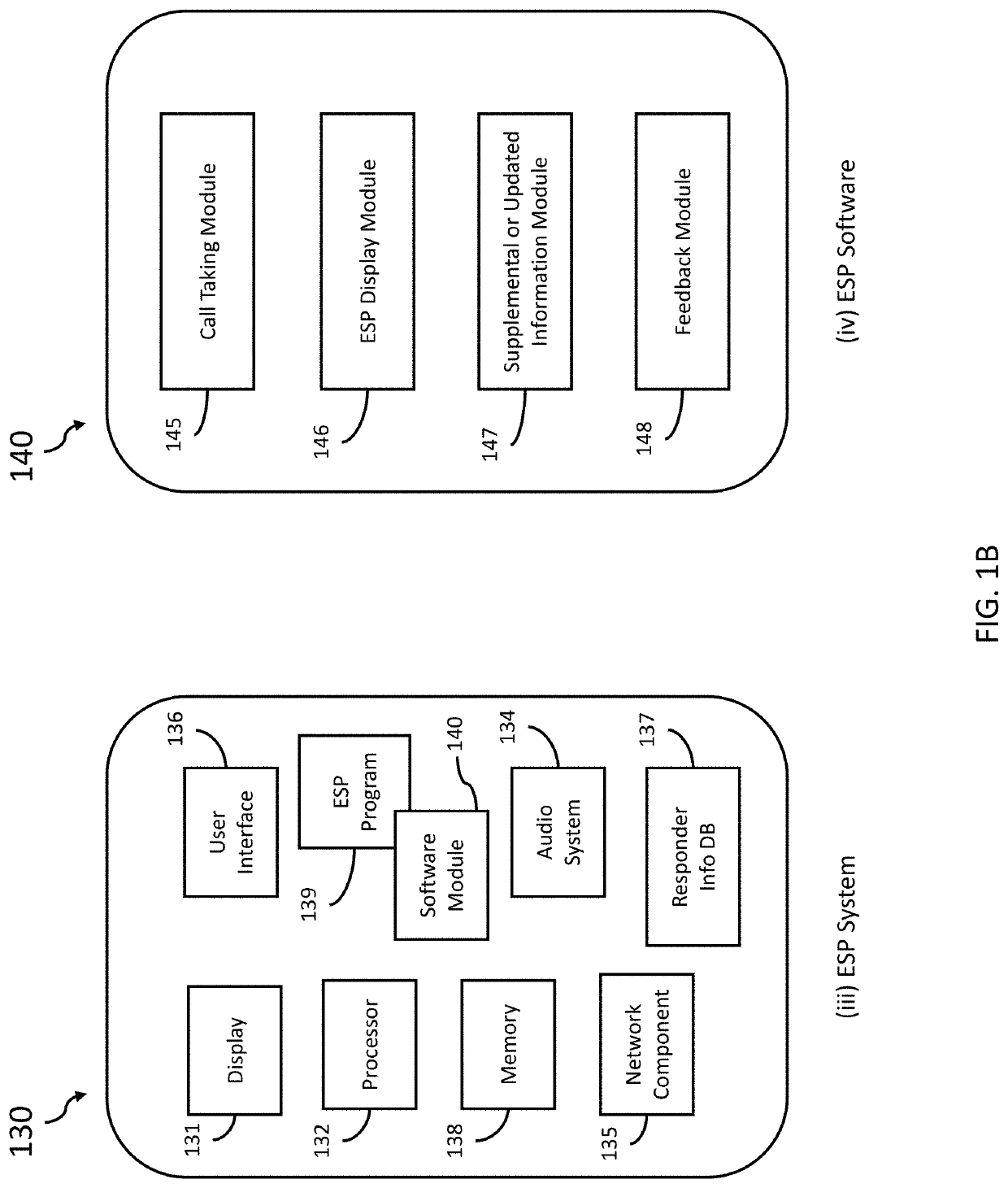

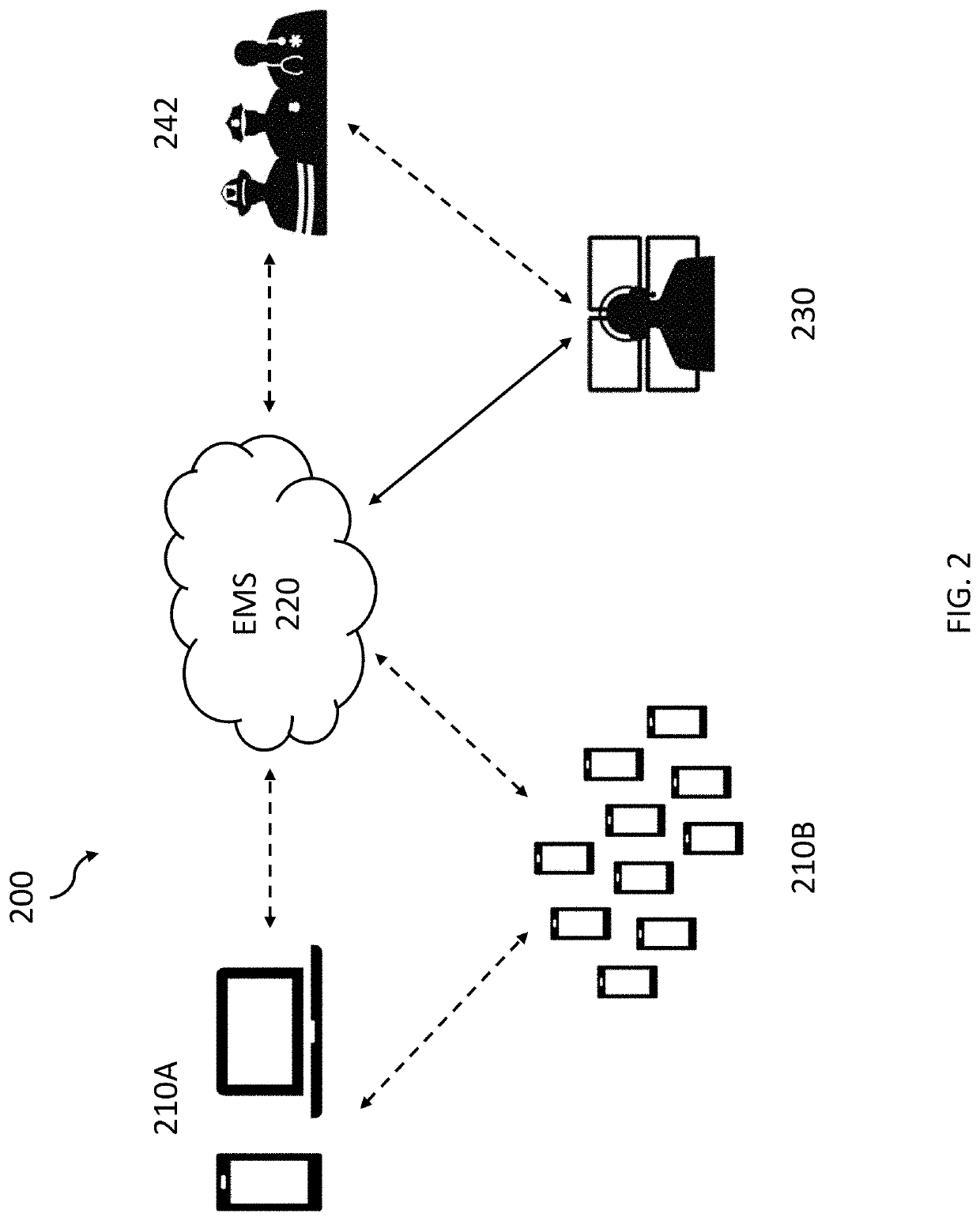

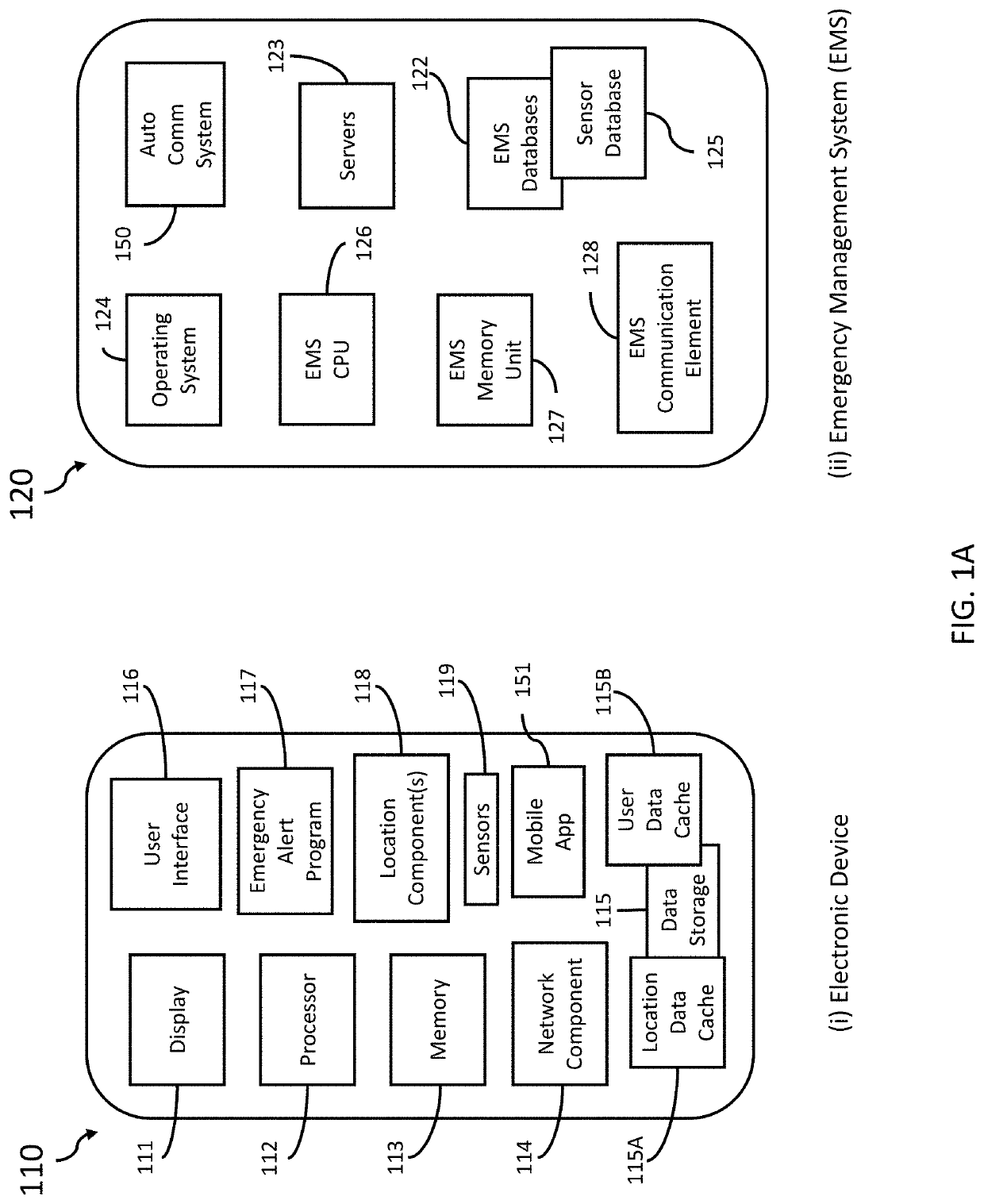

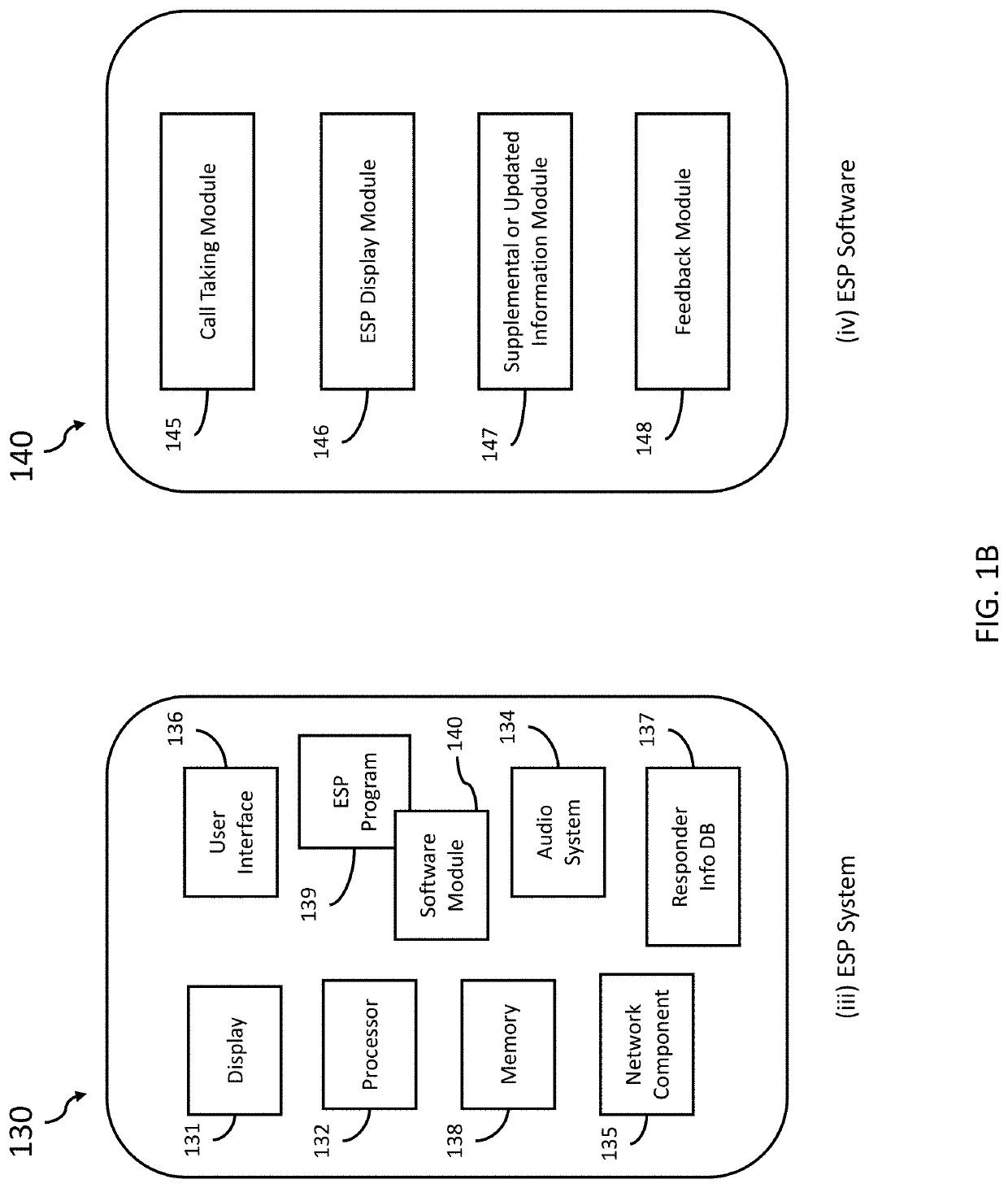

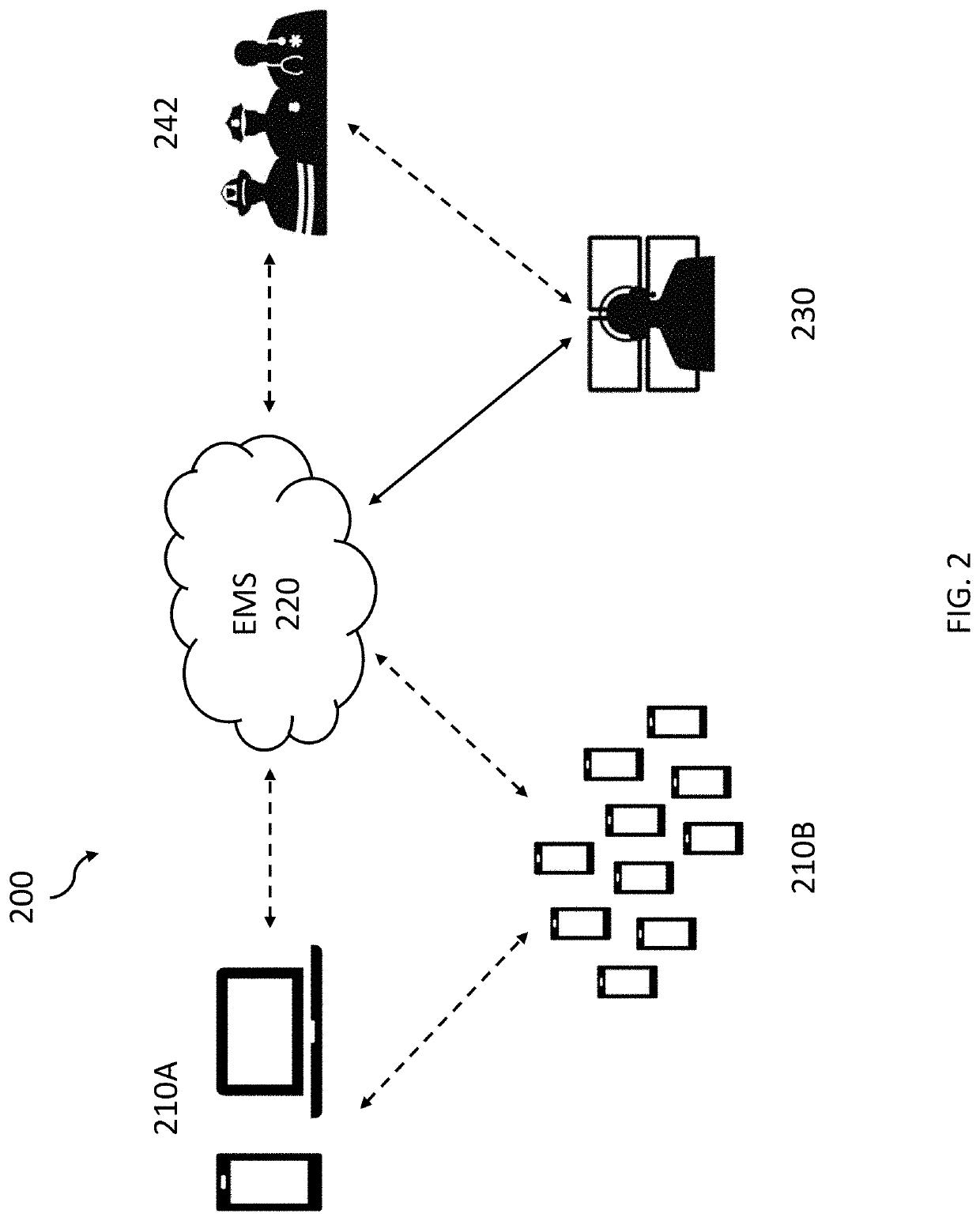

Described herein are systems, devices, methods, and media for connecting a user for transmitting multimedia from electronic devices to emergency service providers. In some embodiments, a method for transmitting multimedia from an electronic device to an emergency service provider by an emergency management system includes the steps of: detecting an emergency alert indicative of an emergency; wherein each sensor within the set of pertinent sensors is determined to be associated with the emergency; obtaining a first set of multimedia contents from the set of pertinent sensors; determining, based on at least one of the set of pertinent sensors and the first set of multimedia contents, a set of relevant sensors from the set of pertinent sensors; and transmitting a second set of multimedia contents from the set of relevant sensors to an emergency service provider.

Owner:RAPIDSOS

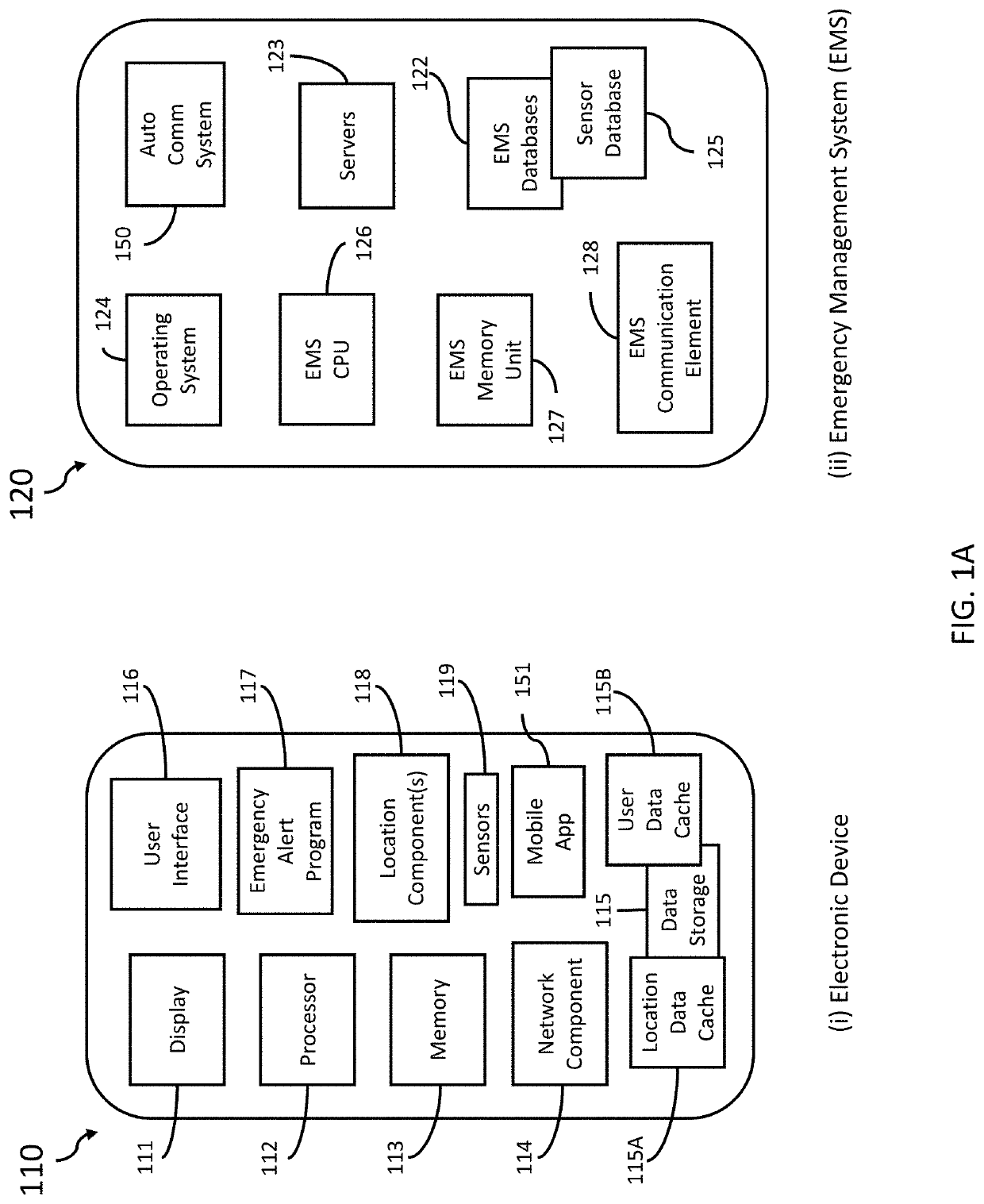

Systems & methods for automated emergency response

ActiveUS20200274962A1Easy to collect and transferSubstation equipmentMessaging/mailboxes/announcementsEmergency encounterEngineering

Described herein are systems, devices, methods, and media for facilitating emergency communications by an emergency management system. In one embodiment, a method for facilitating emergency communications comprises: identifying a user potentially affected by an emergency; providing an emergency response message to a communication device associated with the user; receiving confirmation of the emergency; in response to receiving confirmation of the emergency, initiating an autonomous communication session with the user through the communication device; extracting emergency information from the autonomous communication session; and providing the emergency information to an emergency service provider (ESP).

Owner:RAPIDSOS

Systems and methods for automated emergency response

ActiveUS11218584B2Easy to collect and transferSubstation equipmentMessaging/mailboxes/announcementsEmergency encounterEngineering

Described herein are systems, devices, methods, and media for facilitating emergency communications by an emergency management system. In one embodiment, a method for facilitating emergency communications comprises: identifying a user potentially affected by an emergency; providing an emergency response message to a communication device associated with the user; receiving confirmation of the emergency; in response to receiving confirmation of the emergency, initiating an autonomous communication session with the user through the communication device; extracting emergency information from the autonomous communication session; and providing the emergency information to an emergency service provider (ESP).

Owner:RAPIDSOS

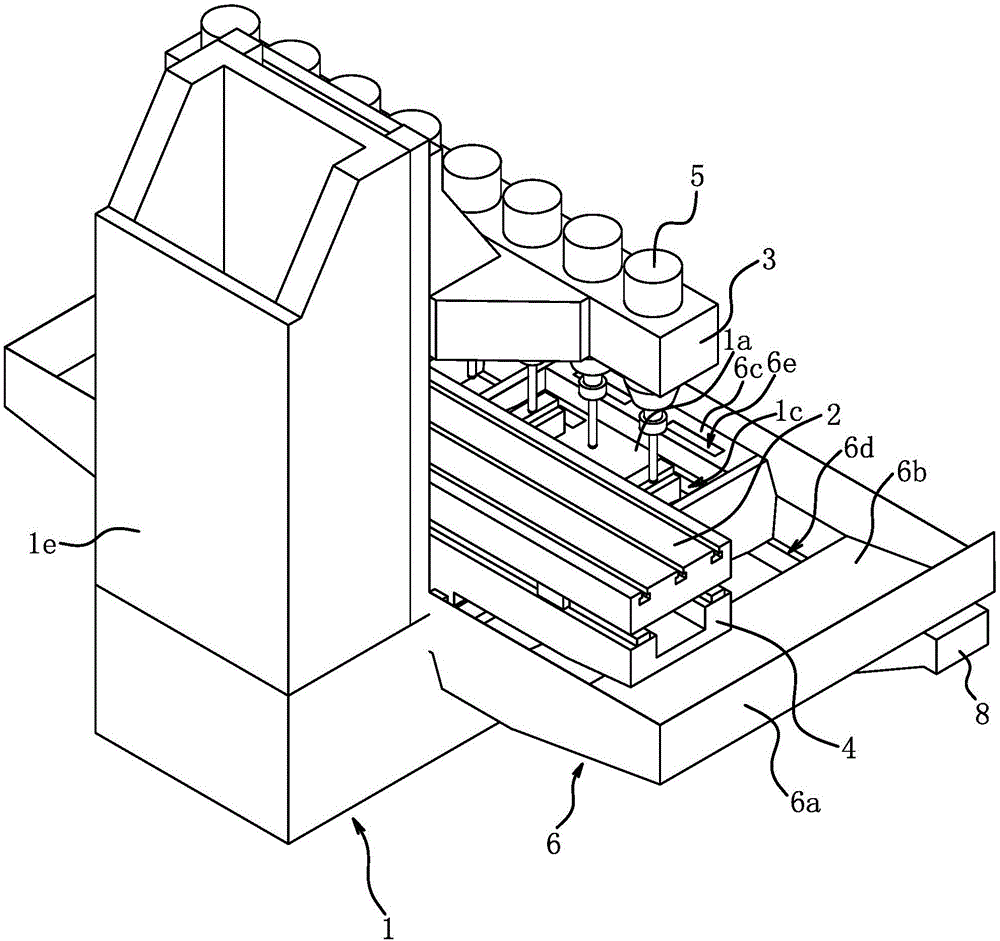

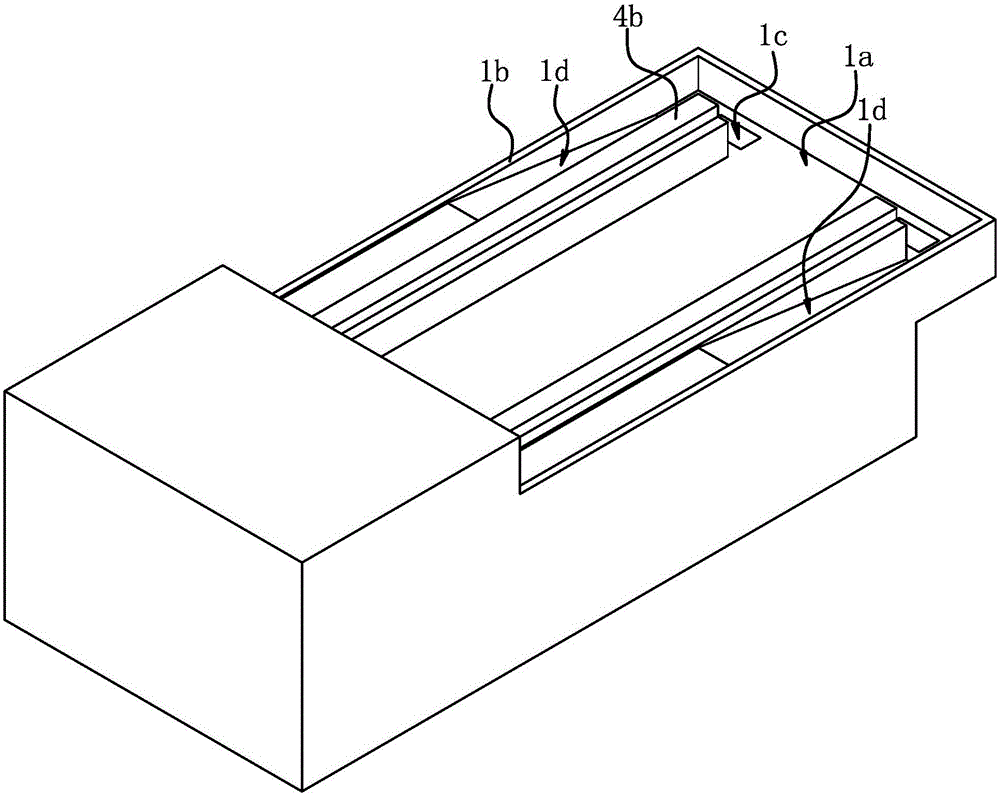

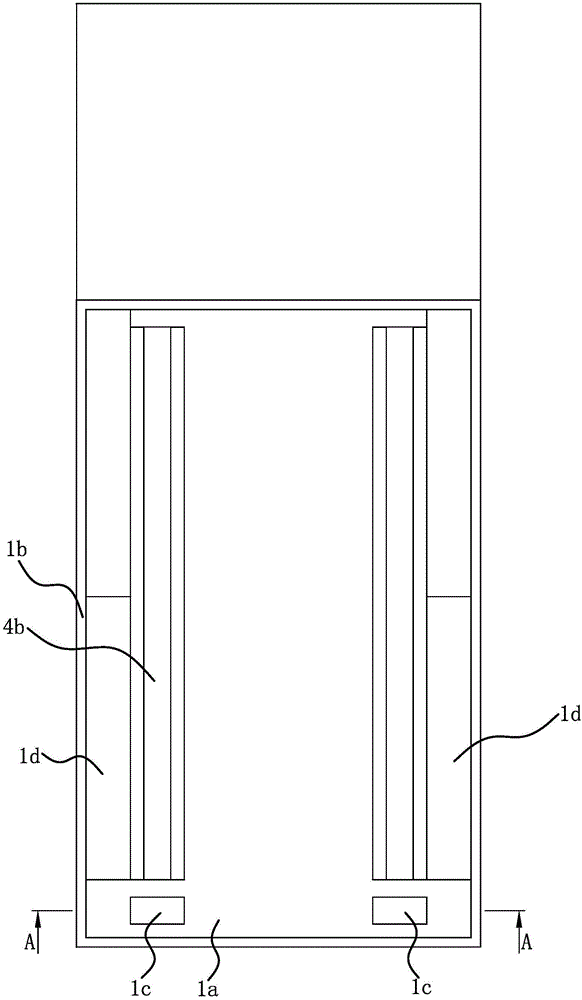

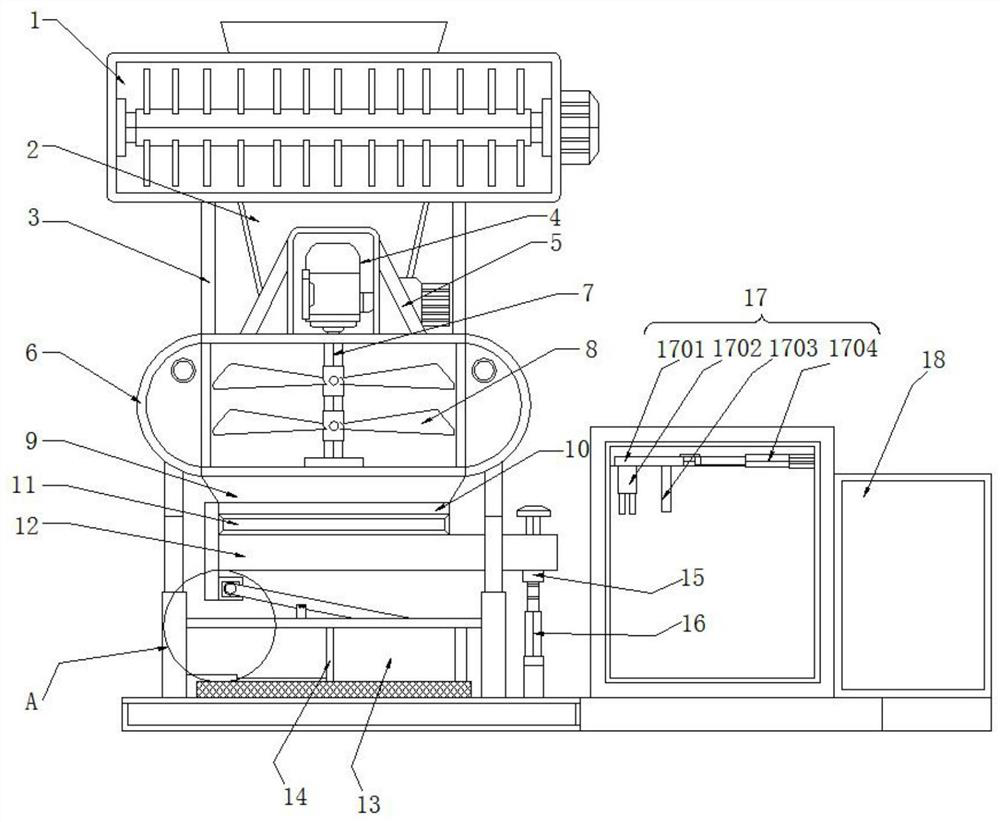

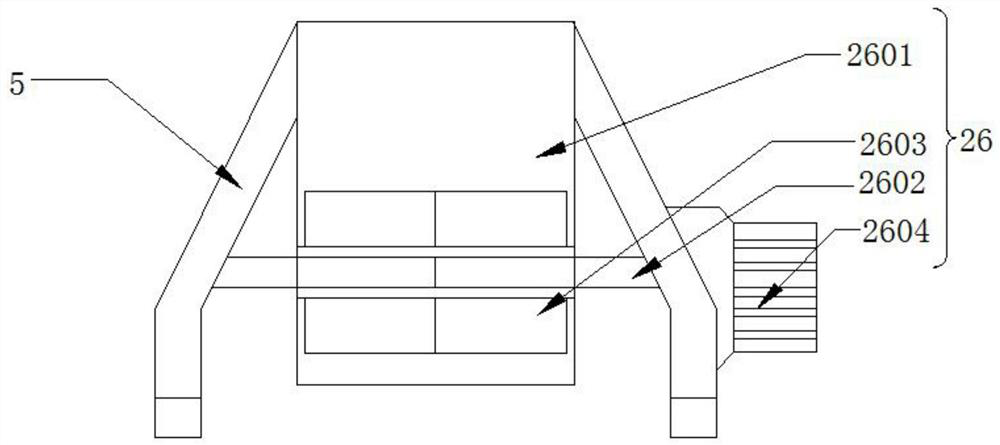

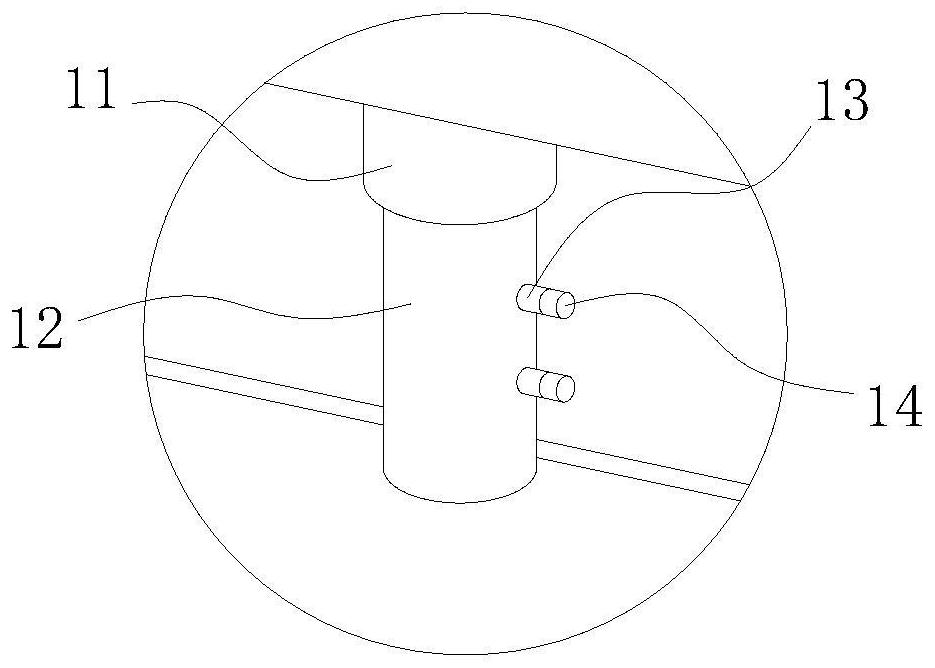

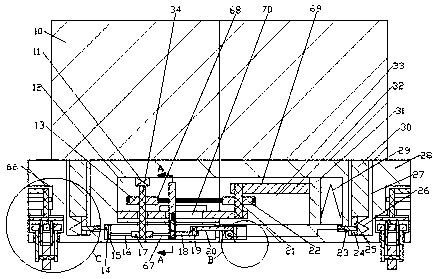

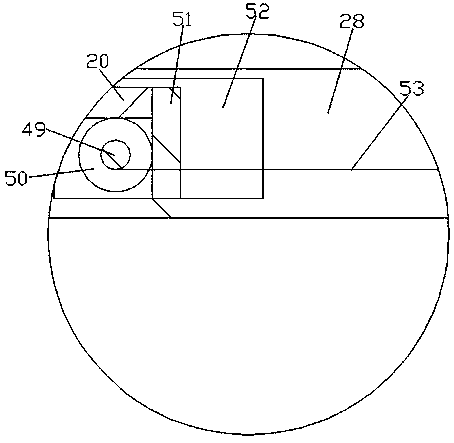

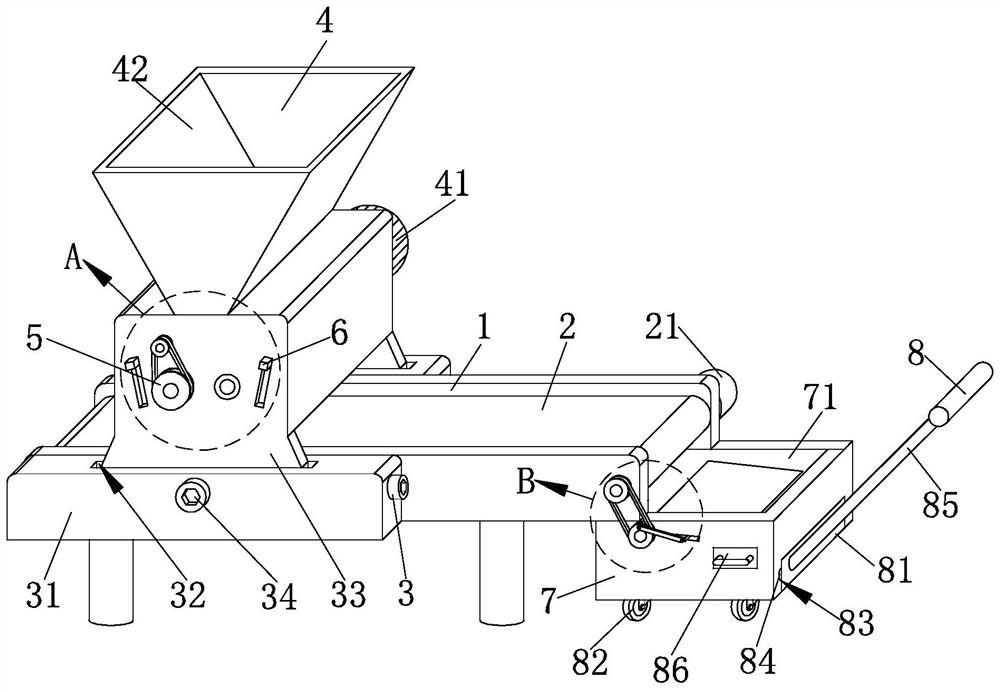

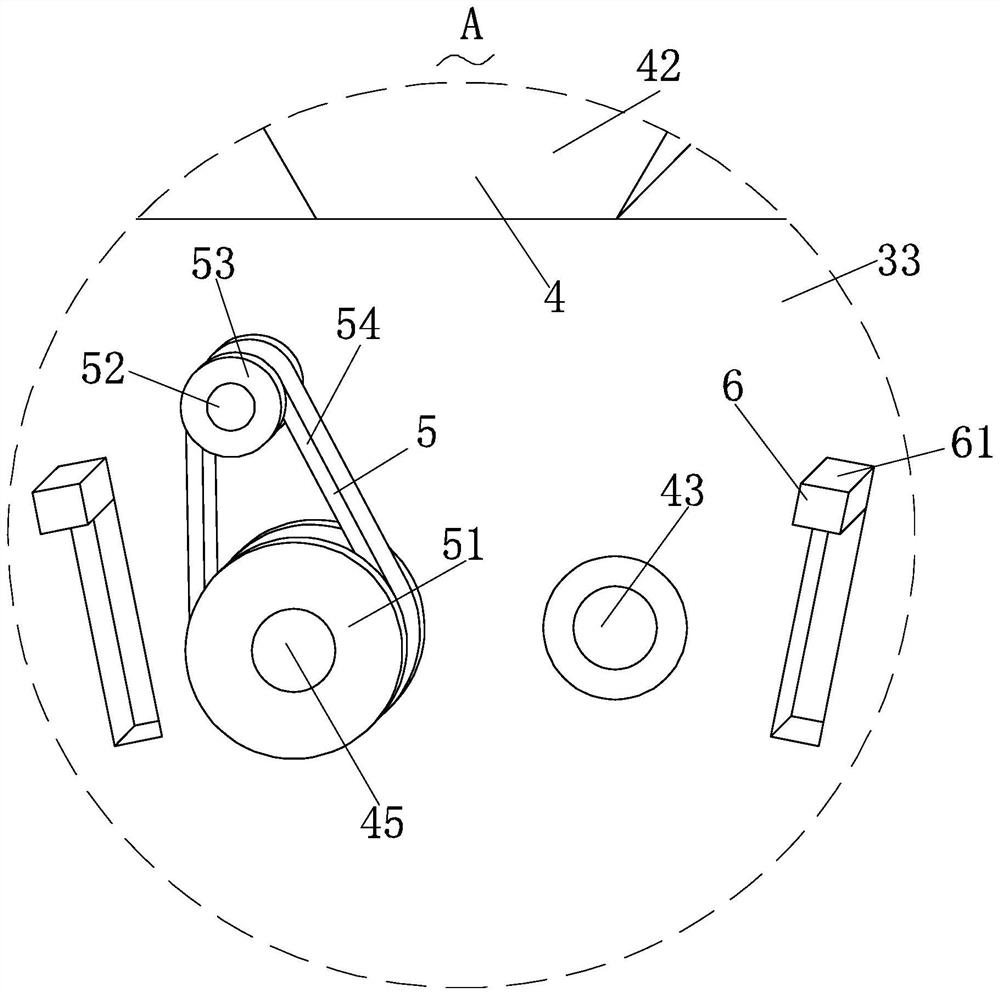

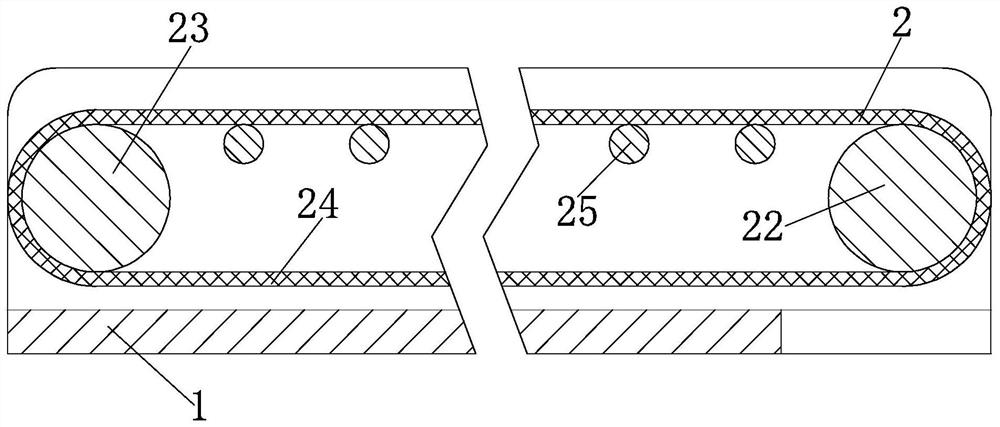

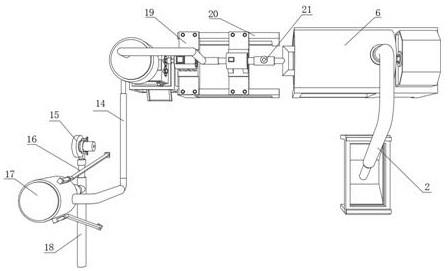

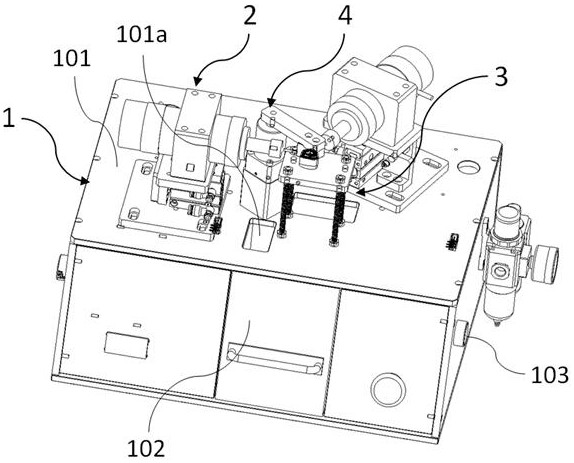

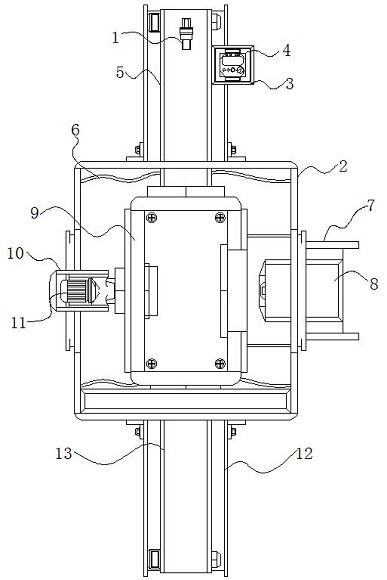

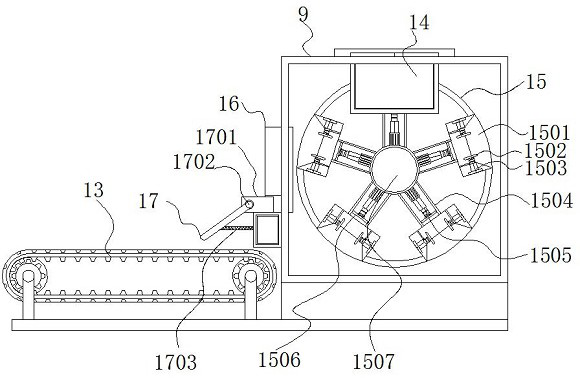

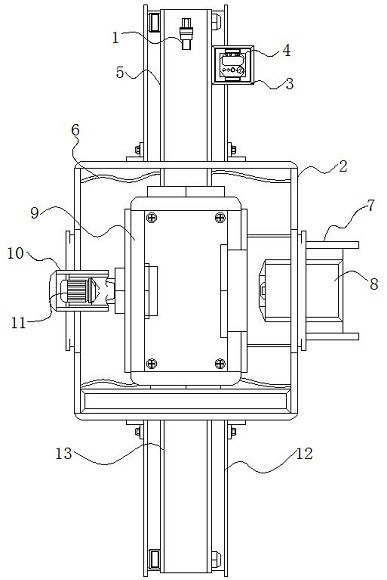

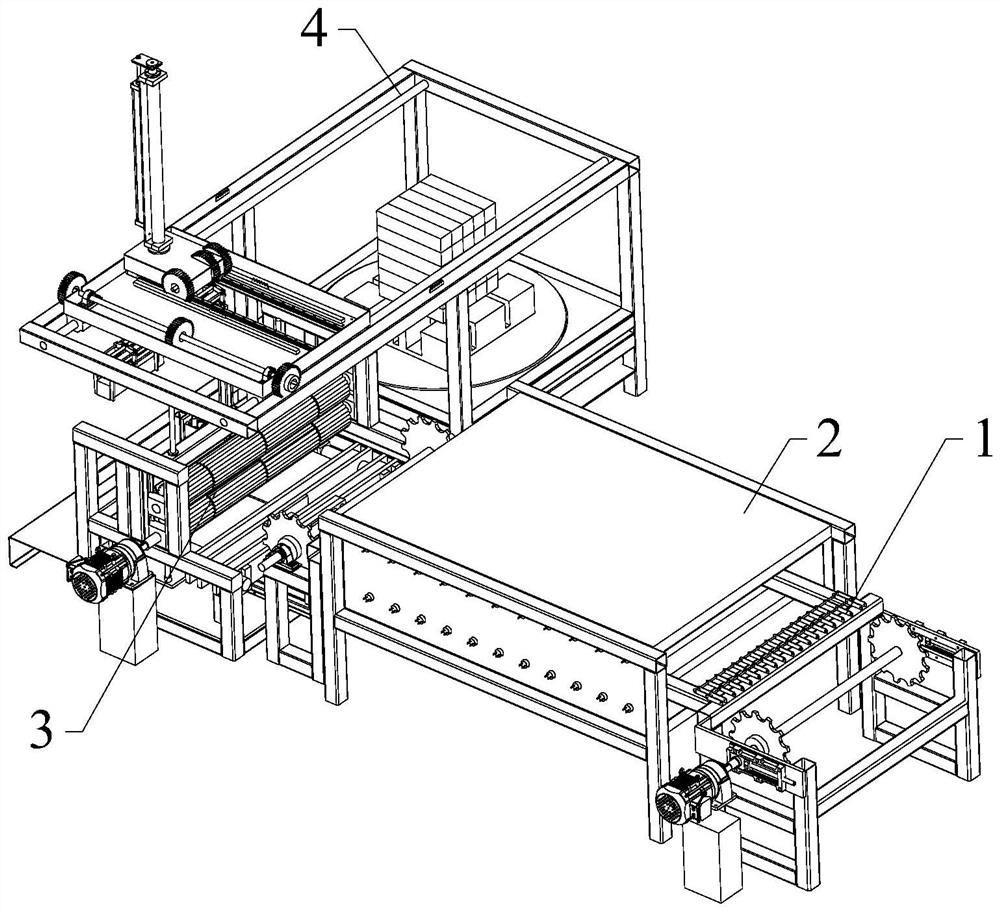

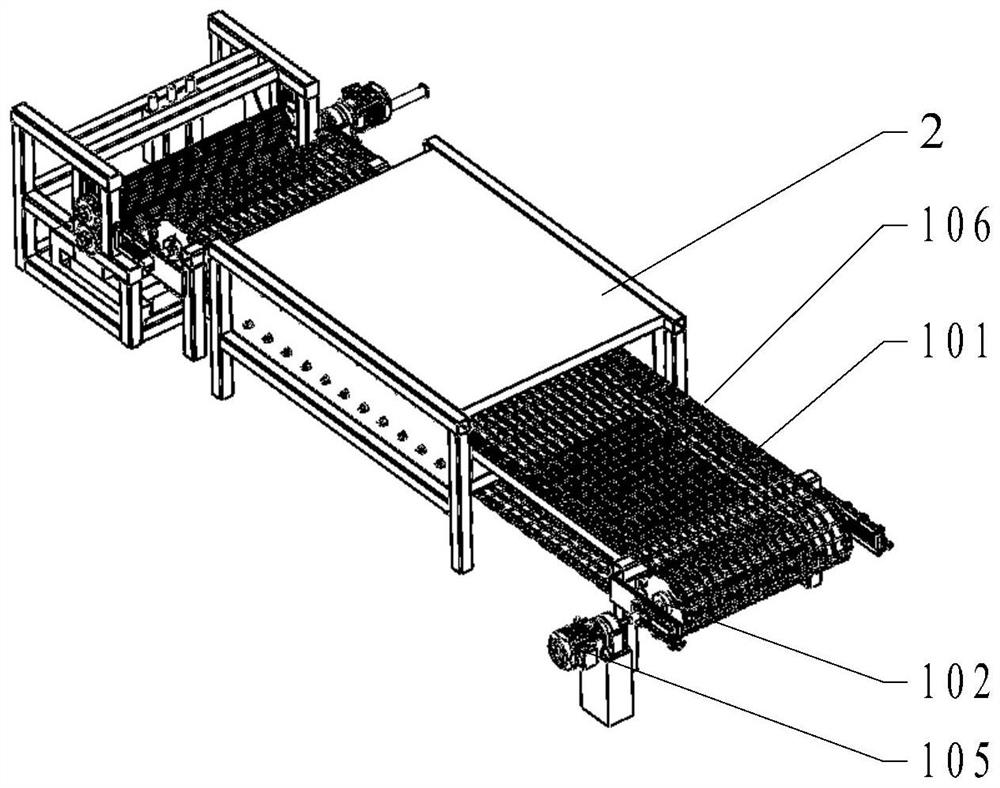

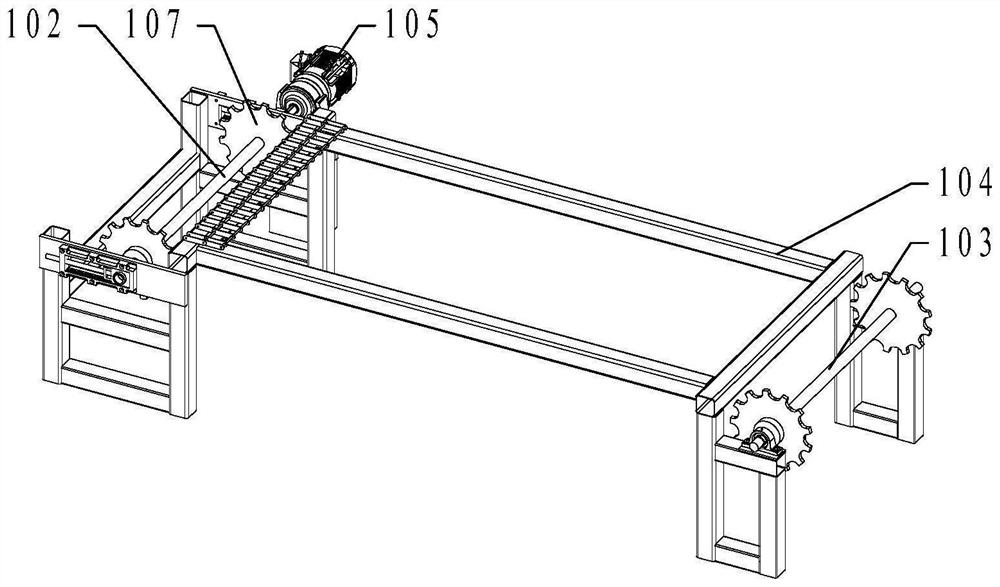

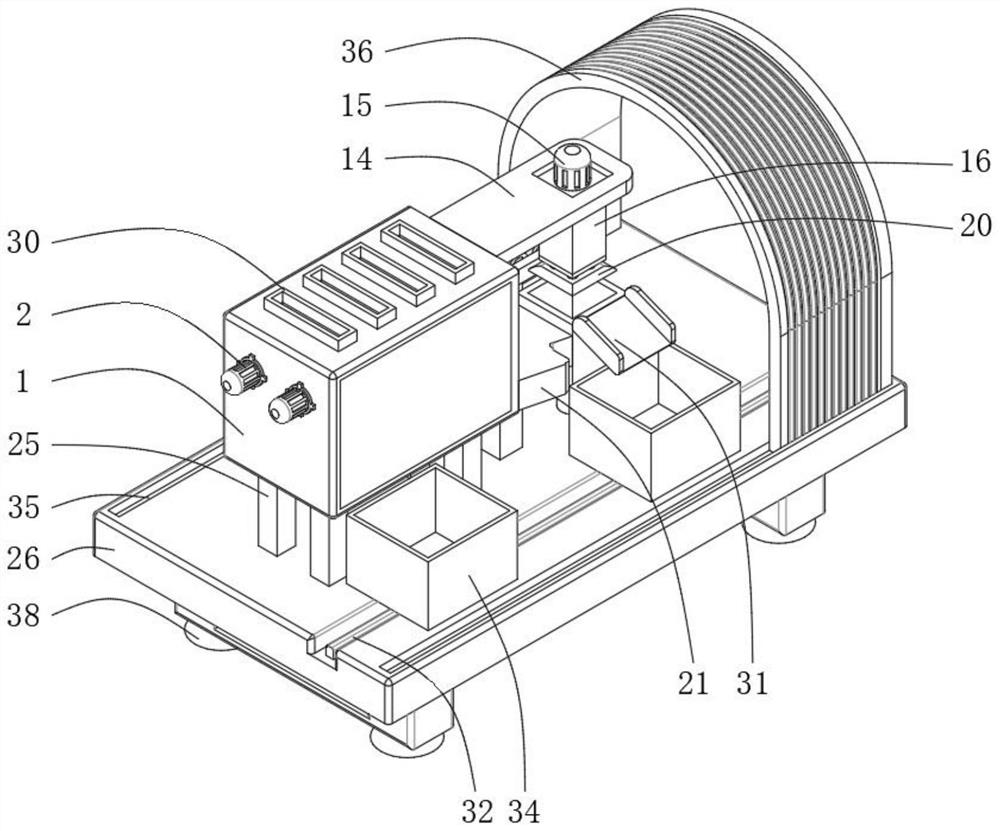

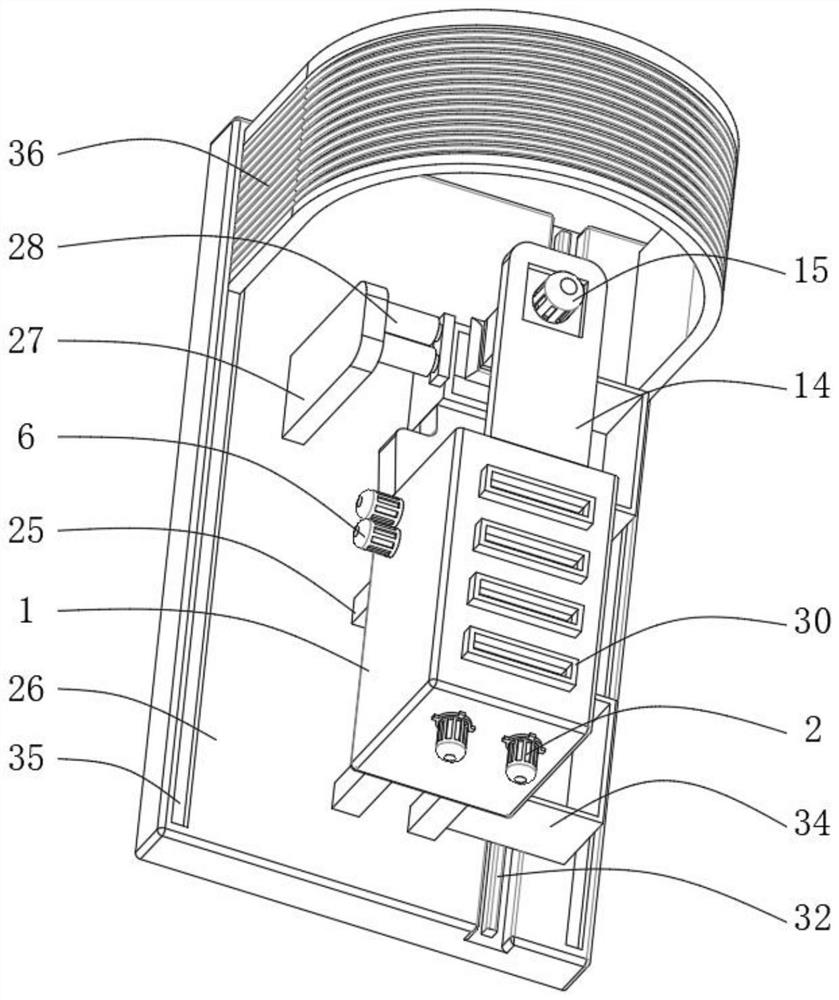

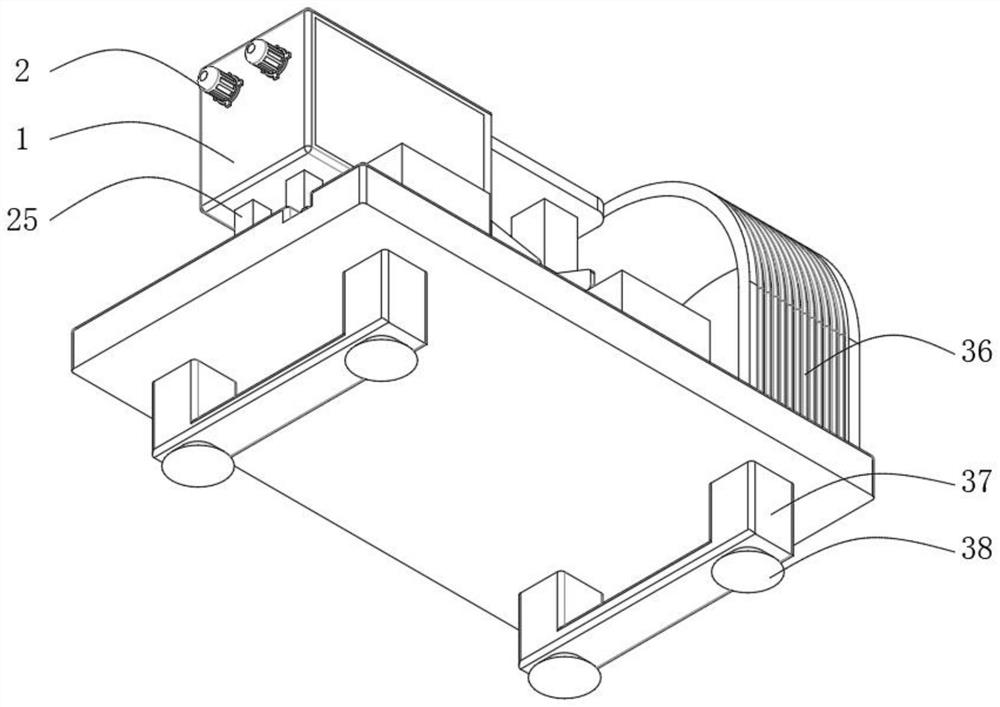

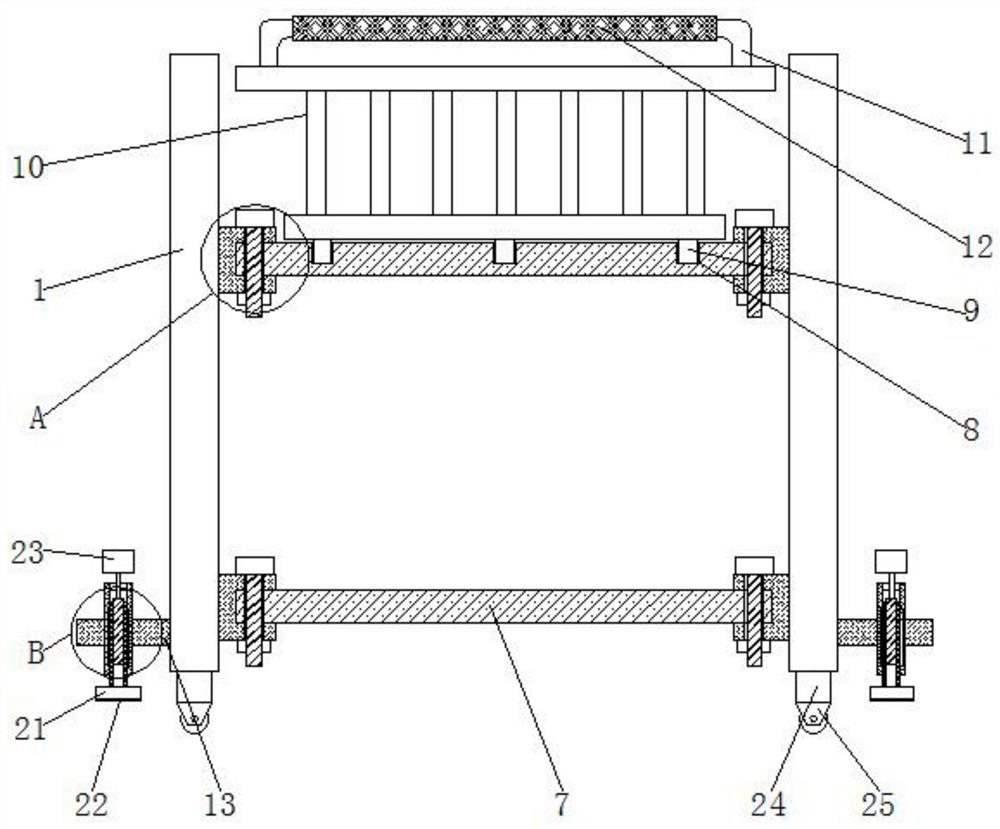

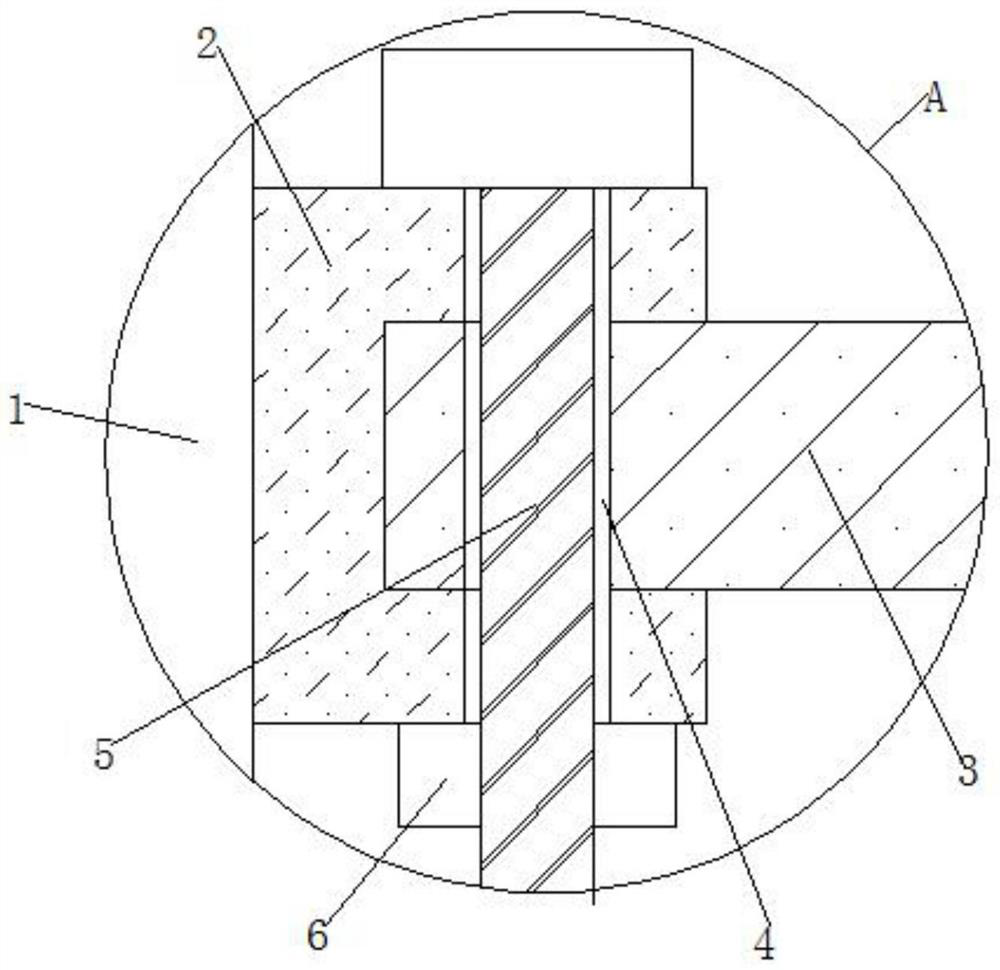

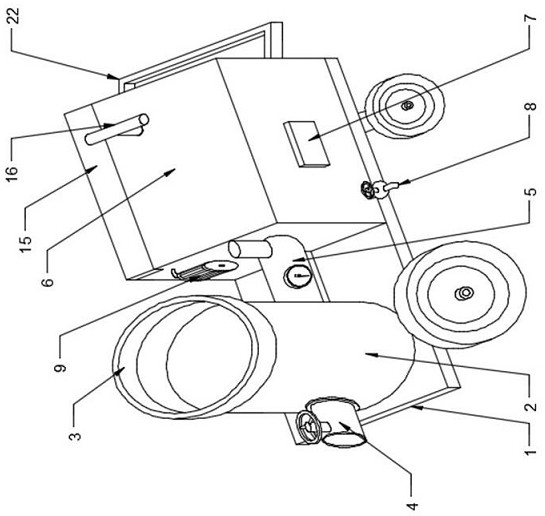

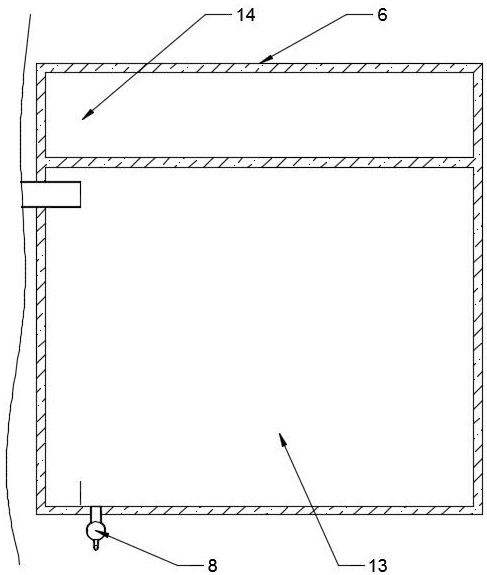

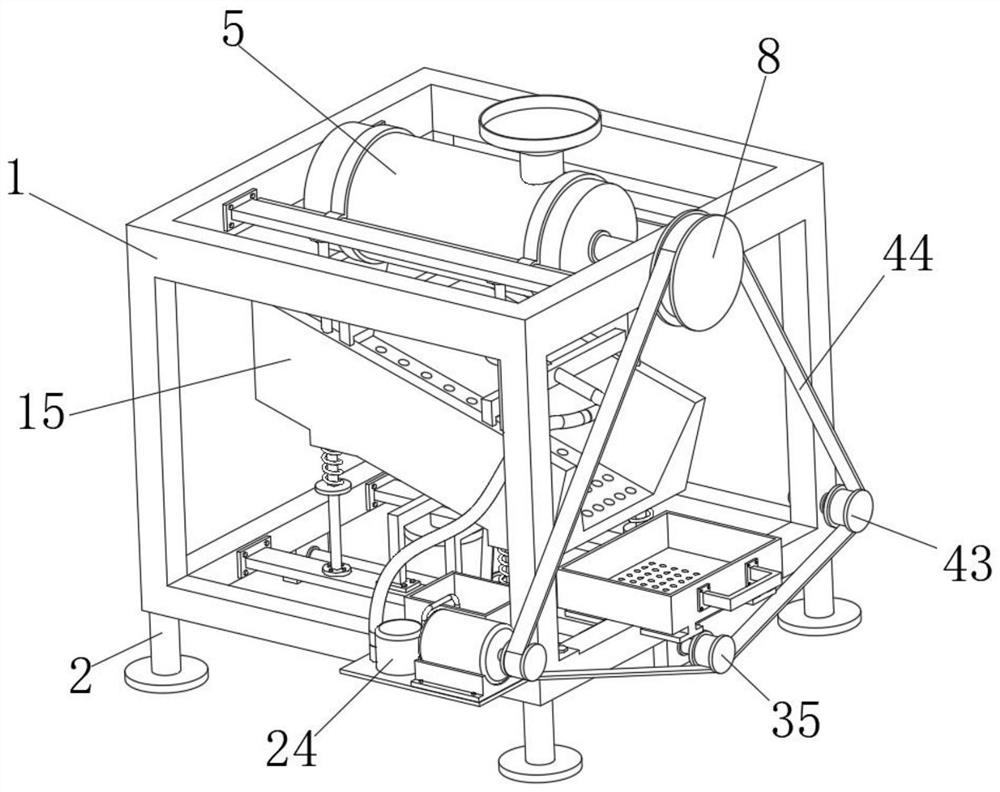

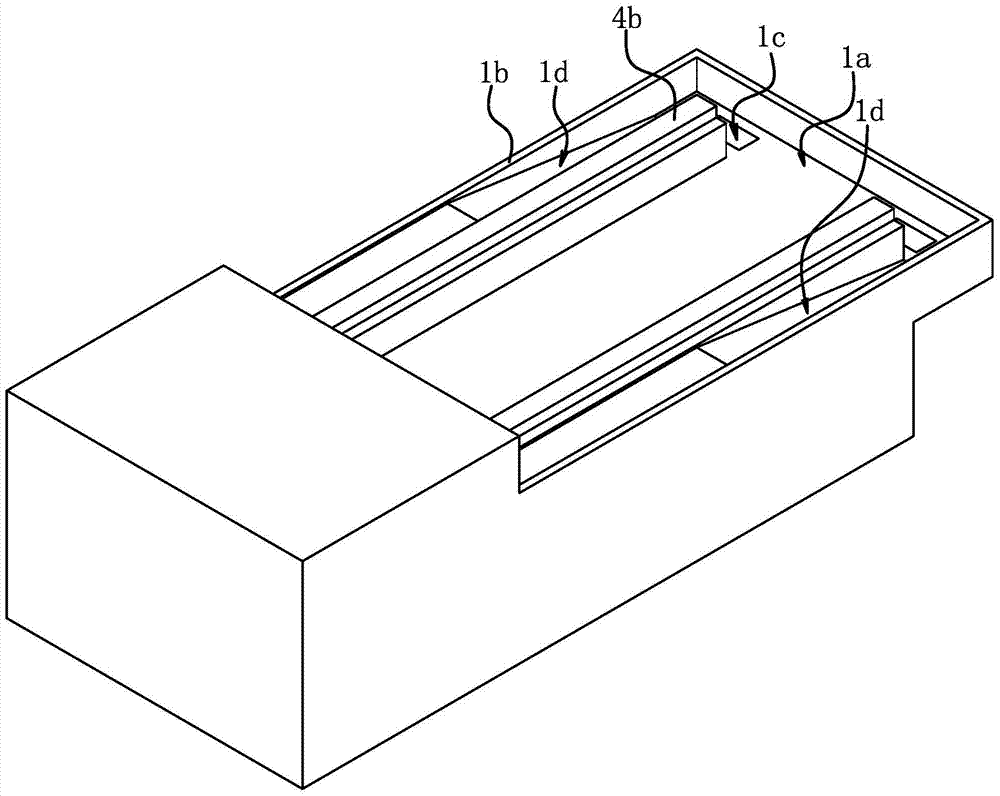

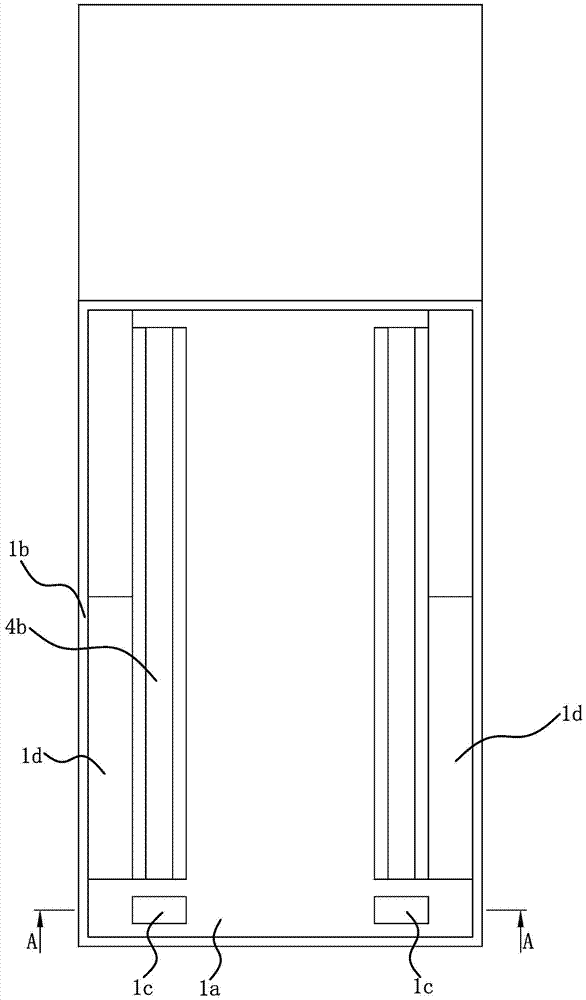

Multi-station vertical engraving and milling machine

ActiveCN105081781AReduce weightEasy to collectOther manufacturing equipments/toolsLarge fixed membersEngravingWater block

The invention provides a multi-station vertical engraving and milling machine and belongs to the technical field of operation. The multi-station vertical engraving and milling machine solves the problem that copper scraps in an existing engraving and milling machine are accumulated on a workbench and cannot be easily cleaned away. The multi-station vertical engraving and milling machine comprises a base, a workbench, a lifting base, a machine hood and a plurality of cutting motors. The workbench is connected with the base through a cross pulling plate with a transverse pulling plate and a longitudinal pulling plate. The front end of the base is provided with a cornice part protruding out of the front side. The outer edge of the base is provided with a strip-shaped water blocking part. The cornice part is provided with a scrap falling hole. The machine hood is provided scrap guiding funnel parts which are located below the two ends of the transverse plugging plate and each in the shape of a funnel, and the scrap guiding funnel parts of the machine hood are fixed to the top face of the water blocking part. According to the multi-station vertical engraving and milling machine, the scrap guiding funnel parts of the machine hood are arranged on the two sides to collect cutting bits, the machine hood is a sheet metal part and small in weight, and therefore the situation that the weight of the engraving and milling machine is too large is effectively avoided, and the engraving and milling machine is suitable for being disassembled and assembled through a common loading machine.

Owner:陈美青

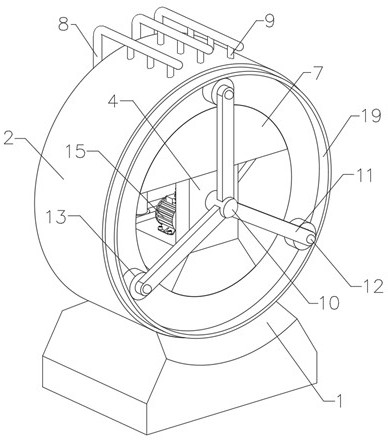

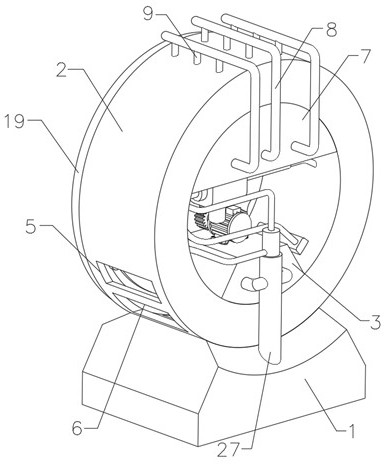

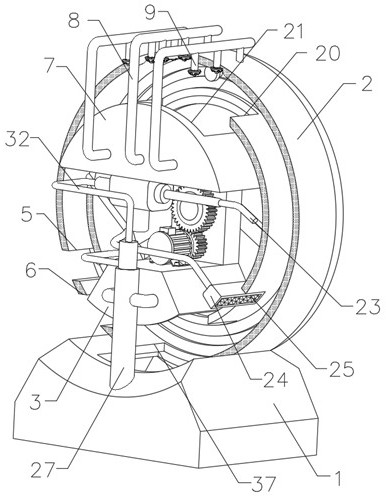

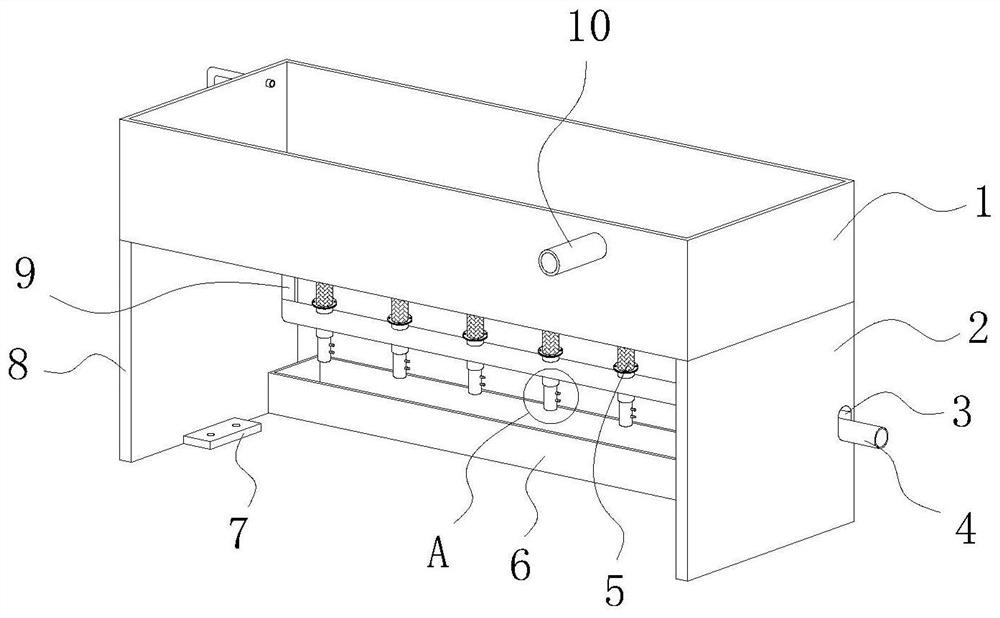

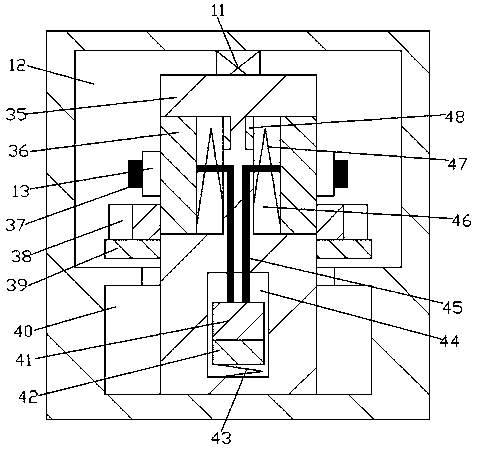

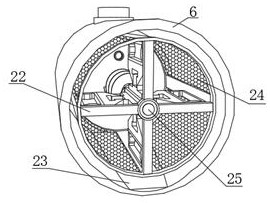

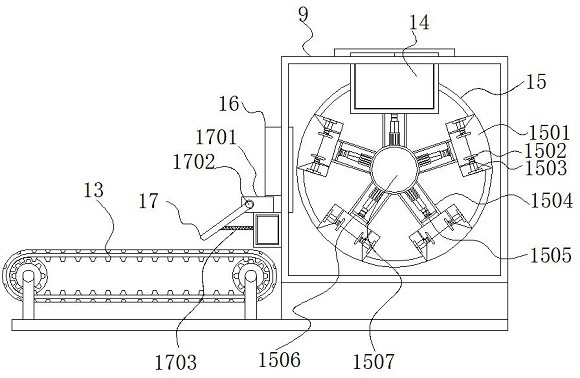

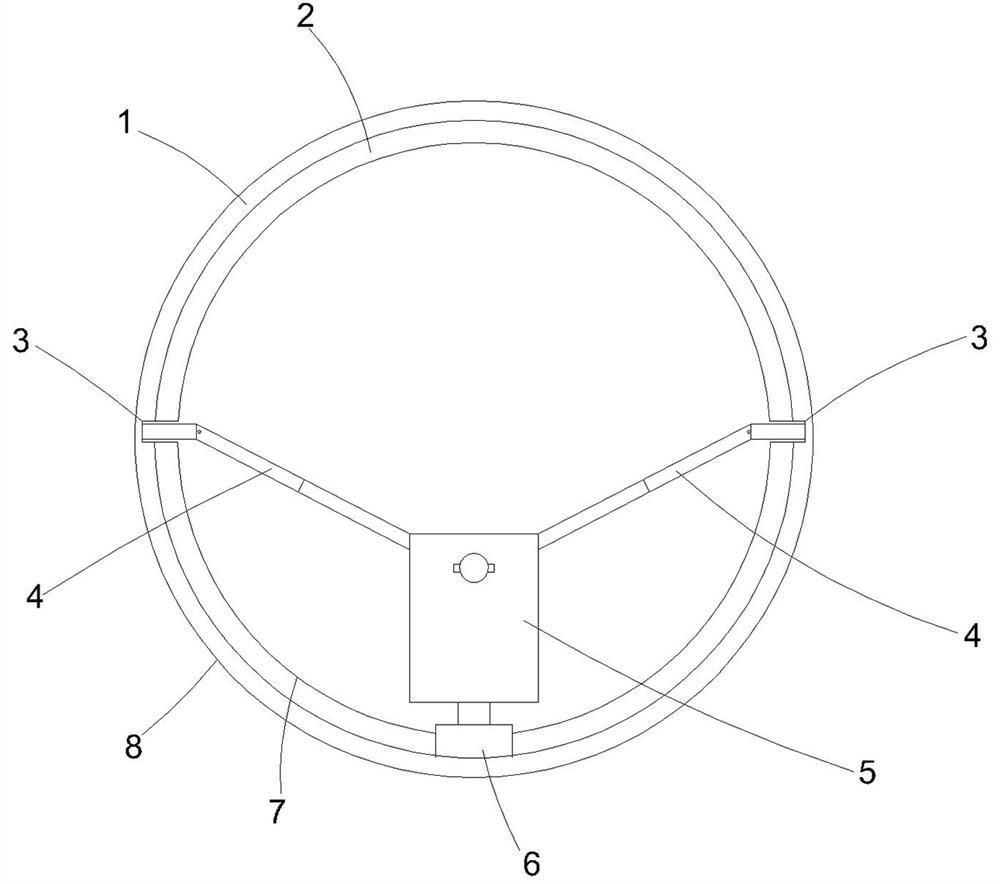

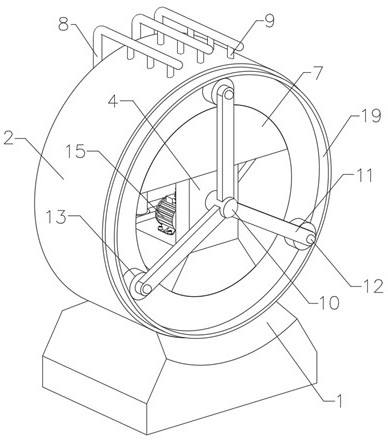

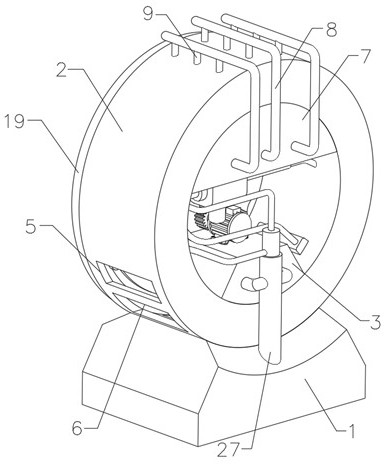

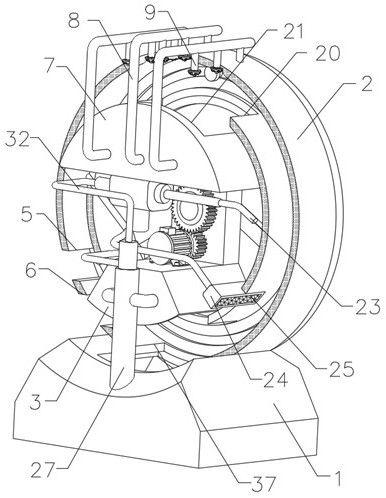

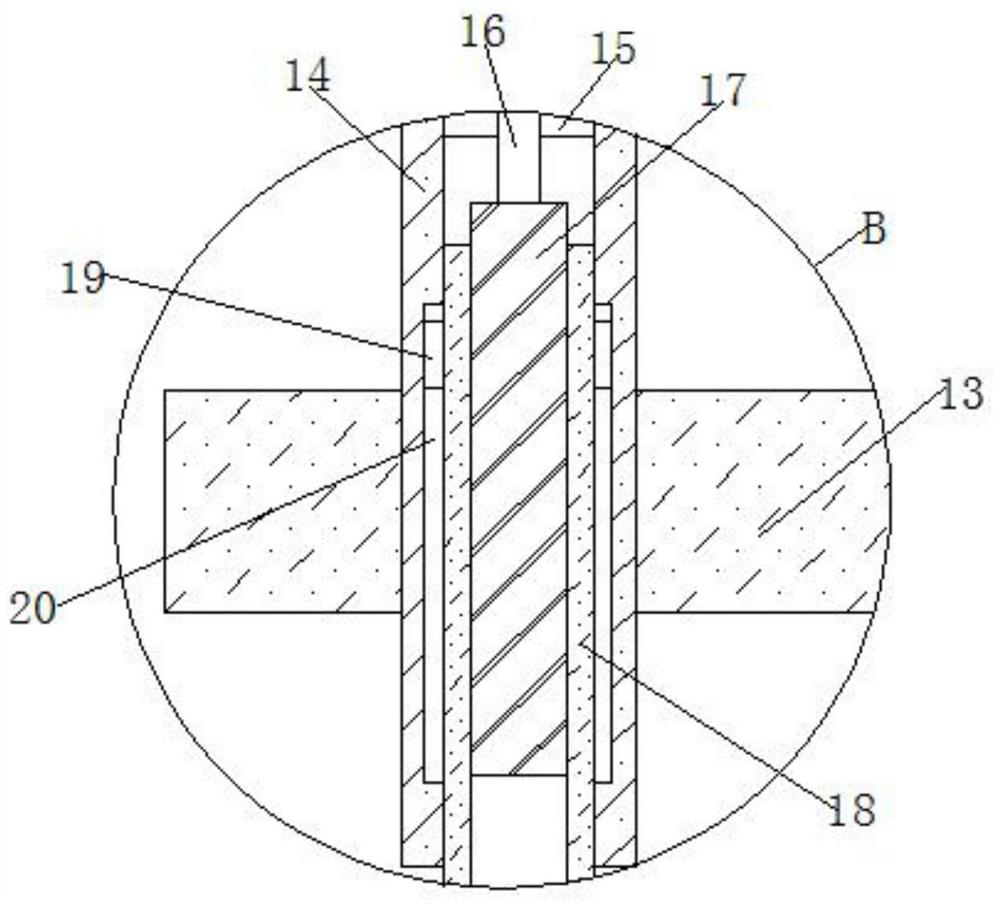

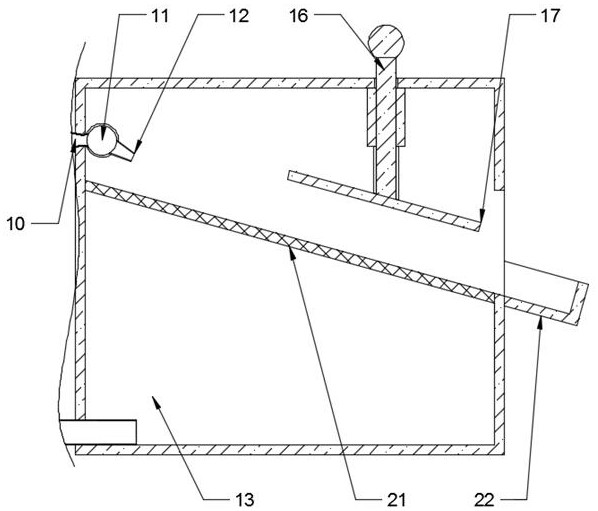

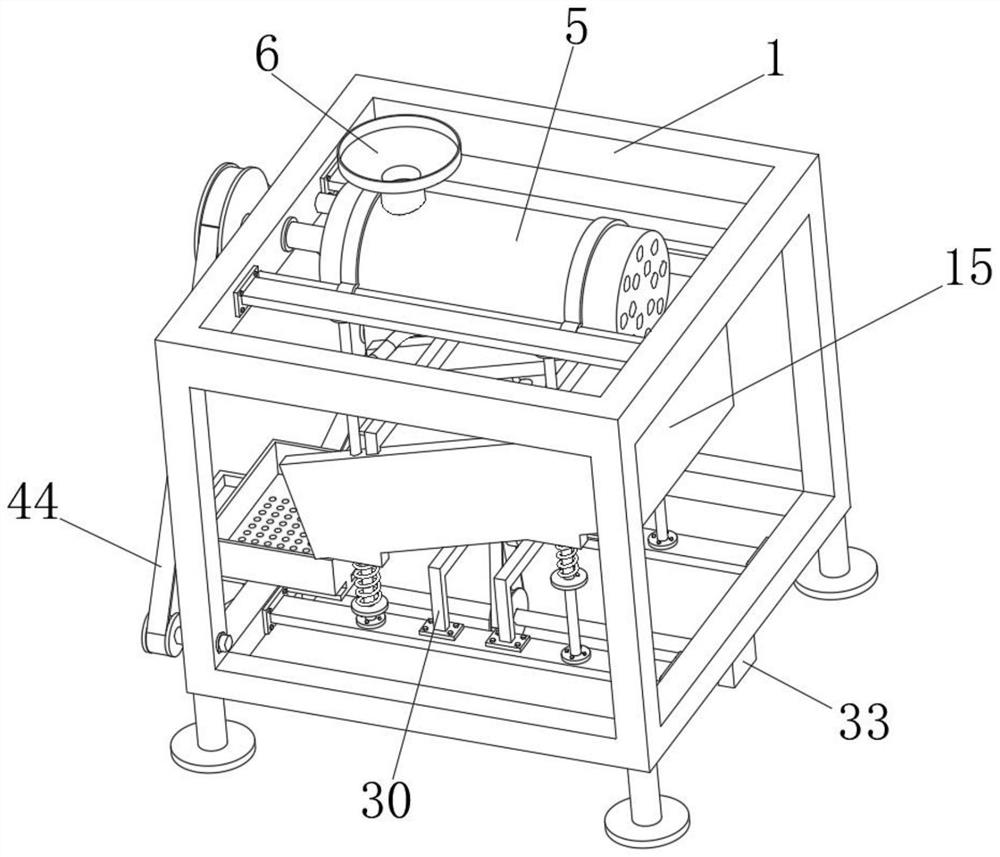

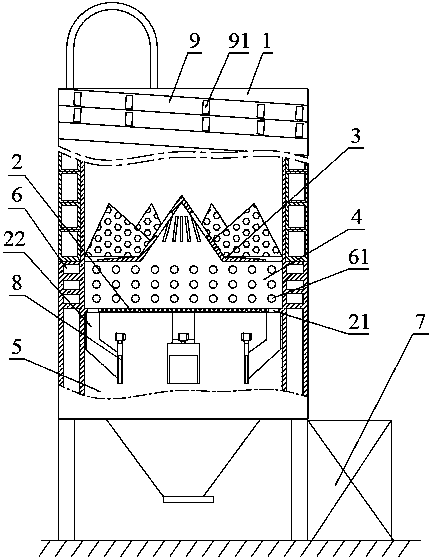

Anti-corrosion treatment device for ventilation fan blade machining

ActiveCN113275304AReduce uncertaintyThe feeding process is stable and effectiveCompression machinesDrying gas arrangementsWater flowEngineering

The invention discloses an anti-corrosion treatment device for ventilation fan blade machining. The anti-corrosion treatment device for ventilation fan blade machining comprises a water tank, wherein a treatment box is fixed to the upper end of the water tank, a building table is fixed to the lower portion of the inner side of the treatment box, a driving mechanism is arranged at the upper end of the building table, and a charging port and a discharging port are formed in the circumferential outer wall of the treatment box in a penetrating mode; and a paint box is fixed to the upper portion of the inner side of the treatment box, a backflow groove is formed in the upper wall of the paint box in a penetrating mode, and a collecting groove communicating with the backflow groove is formed in the inner wall of the treatment box in a penetrating mode. The anti-corrosion treatment device for ventilation fan blade machining has the following advantages: uncertainty caused by manual loading is reduced due to automatic loading and unloading, so that that a stable and effective loading process is ensured, the overall efficiency is effectively increased through circular machining, blades are washed by water flow to be cleaned, dust and stains cannot be carried to enter the subsequent steps, and therefore the overall spraying anti-corrosion treatment quality is improved; and drying treatment can be carried out on the blades sprayed with the paint through circular flowing of the hot air flow, so that subsequent transfer and storage are facilitated.

Owner:南通清风通用机械有限公司

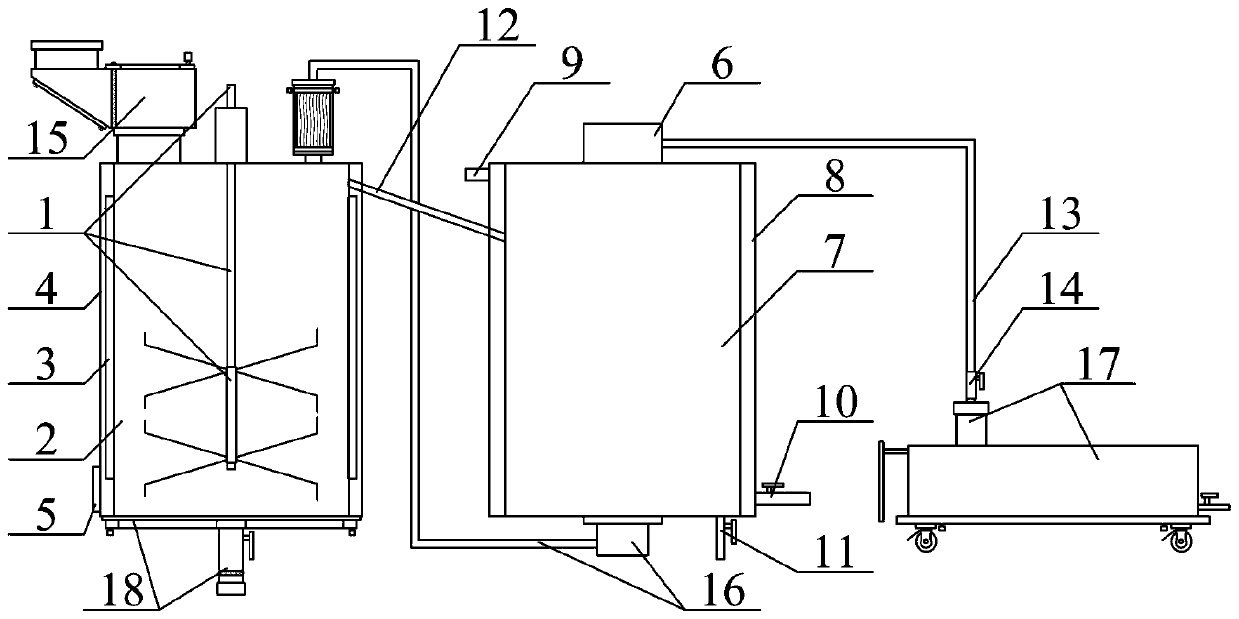

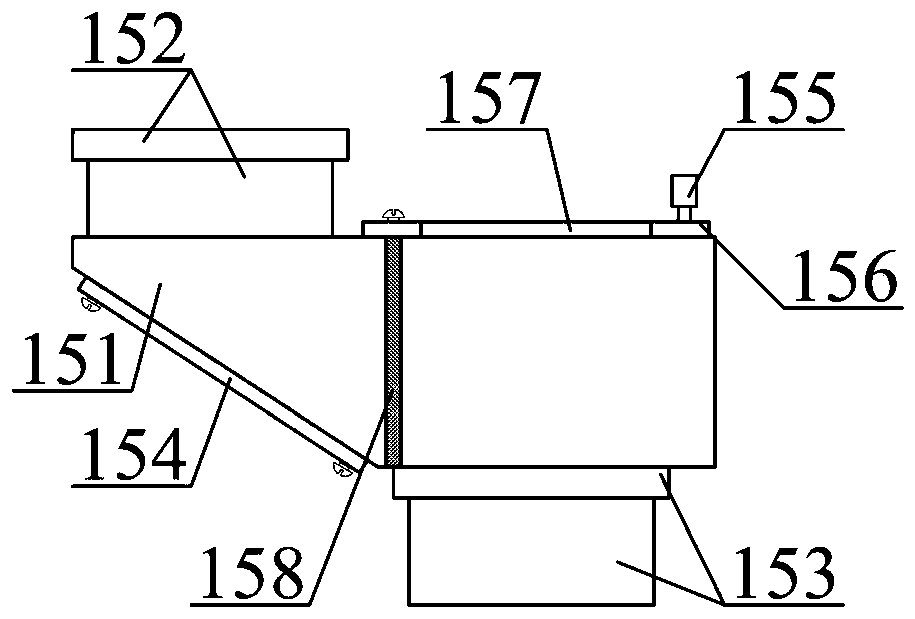

Waste lithium battery electrolyte treatment system and treatment process thereof

ActiveCN113909267AEasy to scatter collectionAffect the service lifeLighting and heating apparatusTransportation and packagingElectrical batteryMechanical engineering

The invention discloses a waste lithium battery electrolyte treatment system and a treatment process thereof, and relates to the technical field of waste lithium battery treatment. Particularly, the waste lithium battery electrolyte treatment system comprises a first processing frame and a second storage cavity, a supporting frame is arranged on the exterior of the bottom of the first processing frame, a second processing frame is mounted on the exterior of the bottom of the supporting frame, a guide belt is arranged in the middle on the exterior of the bottom of the first processing frame, and a stabilizing frame is mounted at one end outside the bottom of the guide belt. According to the waste lithium battery electrolyte treatment system and the treatment process thereof, collection can be carried out on screened batteries by utilizing the design of a first storage cavity in the use process, battery scraps can be conveyed to one side of the interior of the first storage cavity by utilizing the design of an inclined plate in the collection process, a connecting plate can be driven to move by utilizing the design of an electric push rod, therefore, extrusion treatment can be carried out on the battery scraps placed in the interior of the first storage cavity through movement of the connecting plate, collection is conveniently carried out on the battery scraps, and the occupied space is reduced.

Owner:JIANGSU UNIV OF TECH

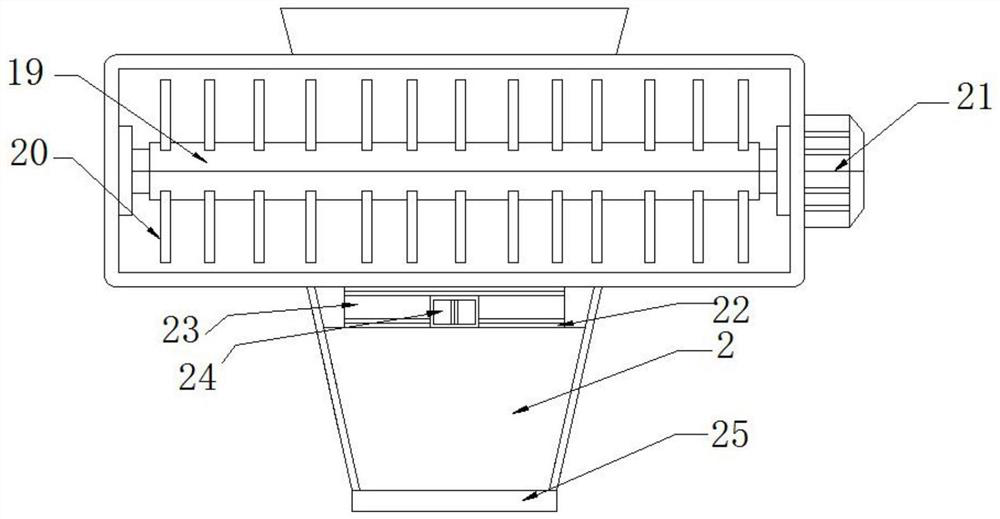

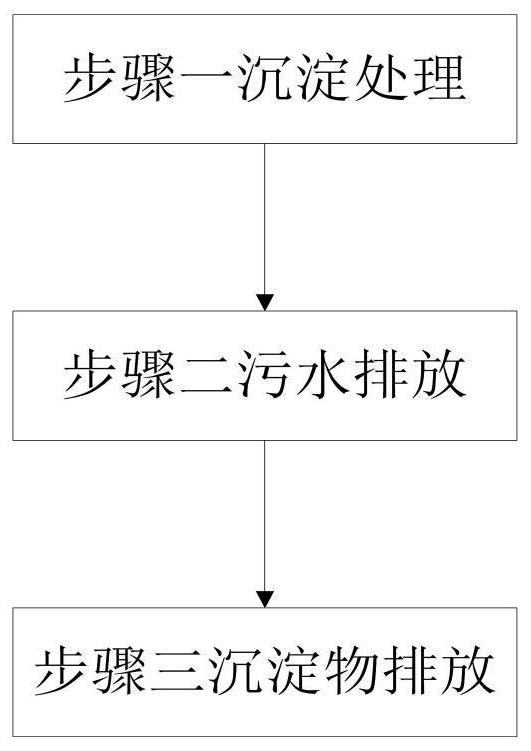

Environment-friendly steel mill wastewater treatment method

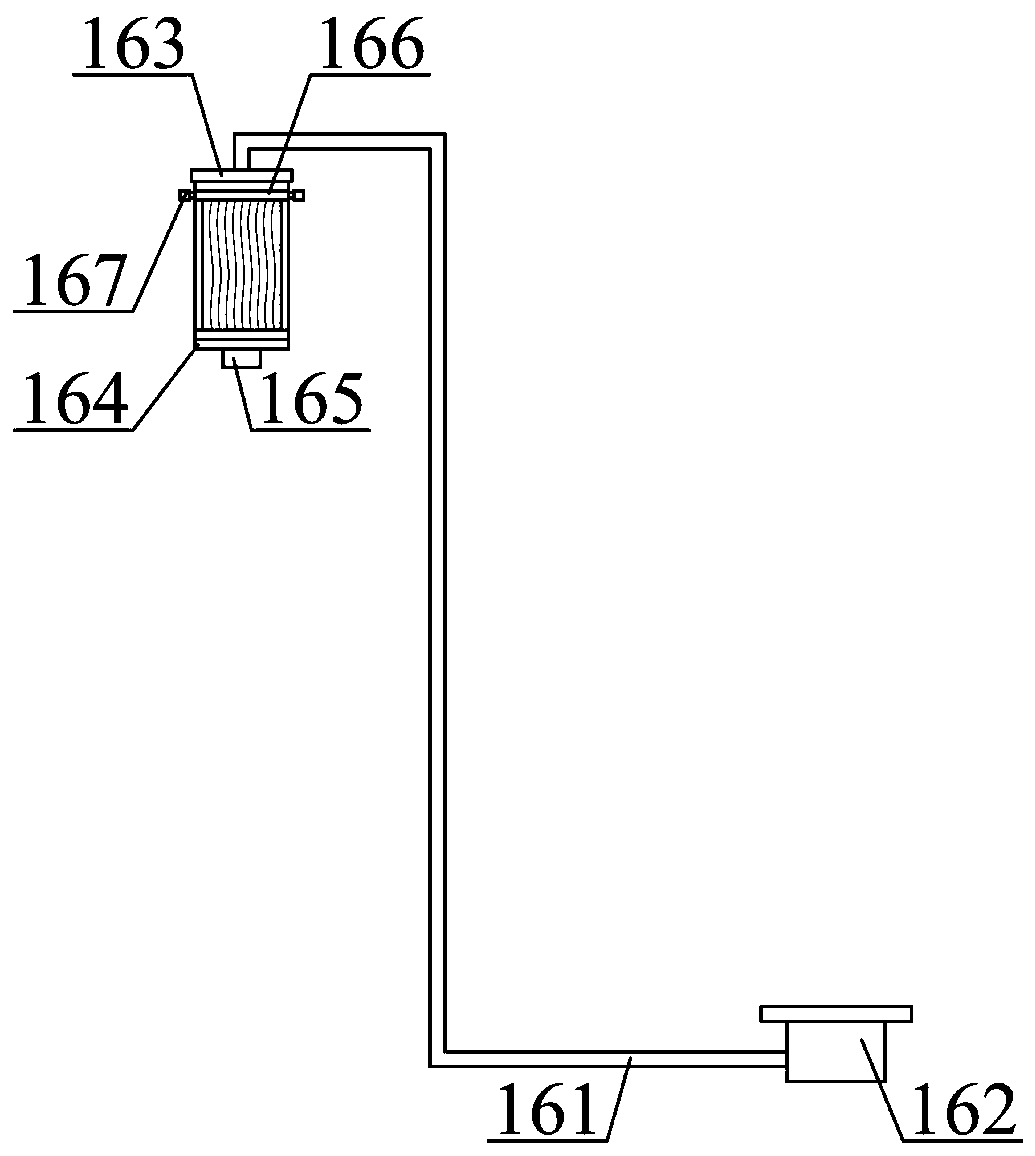

ActiveCN111892139AEasy to tiltReduce waterproof requirementsSettling tanks feed/dischargeWaste water treatment from metallurgical processElectric machineryButterfly valve

The invention relates to the technical field of wastewater treatment, and in particular, relates to an environment-friendly steel mill wastewater treatment method. Wastewater treatment equipment is used in the method. The wastewater treatment equipment is used for carrying out environment-friendly treatment on steel mill wastewater, and environment-friendly treatment comprises a plurality of processes of precipitation treatment, sewage discharge, precipitate discharge and the like; the wastewater treatment equipment is connected with a butterfly valve and a spiral conveyor by utilizing a metalripple compensator; the two ends of the spiral conveyor penetrate through a first limiting groove and a second limiting groove correspondingly; a handle is used for rotating an adjusting screw rod; the adjusting screw rod drives the end, provided with a motor, of the spiral conveyor to move upwards through a traction rope. The inclination angle of the spiral conveyor can be adjusted conveniently,the end, provided with the motor, of the spiral conveyor can be warped upwards conveniently, the requirement for waterproofness of the end, provided with the motor, of the spiral conveyor is lowered,reduction of the production cost is facilitated, the replacement frequency of waterproof parts is reduced, and management is facilitated.

Owner:新余华峰特钢有限公司

Drainage liquid collecting device

PendingCN106620908AAvoid damageEasy to open and closeIntravenous devicesSuction drainage containersEngineeringOpen air

The invention relates to a drainage liquid collecting device. The drainage liquid collecting device comprises a transparent funnel, a contaminant tub and a tub cover used for sealing the upper opening of the contaminant tub, and is characterized in that the funnel is vertically fixed above the tub cover and the neck of the funnel penetrates through the tub cover; the neck of the funnel is provided with a piston I used for opening and closing a funnel passage, and a graduated scale used for marking the intercepting volume of the funnel is arranged on the side surface of the funnel; a blow-off pipe is arranged on the bottom of the contaminant tub, and a piston II used for opening and closing a contaminant discharge channel is arranged on the blow-off pipe. The drainage liquid collecting device has the beneficial effects that during the collecting, measuring and pouring processes of the drainage liquid, the plurality times of transfer in the open air of the drainage liquid is avoided, thus the influences caused to nurses and patients by liquid splashing or foreign smell emission are reduced, the collection and transfer of the drainage liquid are convenient, the workload is alleviated, and recycling is facilitated.

Owner:SHANGHAI CHANGHAI HOSPITAL

Warning device for road engineering construction

ActiveCN110424290ASimple structureEasy to operateTraffic signalsRoad signsRoad engineeringEngineering

The invention discloses a warning device for road engineering construction, and the warning device comprises two supporting blocks, wherein a driving cavity with a right opening is arranged in the supporting block on the left side, a driven cavity with a left opening is arranged in the supporting block on the right side, a driving mechanism for driving the device to operate is arranged in the driving cavity, a moving cavity with a right end wall communicating with an external space is arranged in the lower end wall of the driving cavity, a moving mechanism for controlling the supporting blockon the right side to move left and right is arranged in the moving cavity, the upper end wall of the moving cavity communicates with the driving cavity, the moving mechanism comprises a moving plate with the upper end positioned in the driving cavity, a first connecting rod is fixed on the right end surface of the lower end of the moving plate, when the device works, the device can be divided intotwo parts according to needs, so that warning boards can face two directions to provide warning information for more vehicles or pedestrians, and when the device is not needed to work, the device canbe moved by pushing, and the warning device is convenient to transfer and collect.

Owner:CHINA FIRST HIGHWAY ENG +1

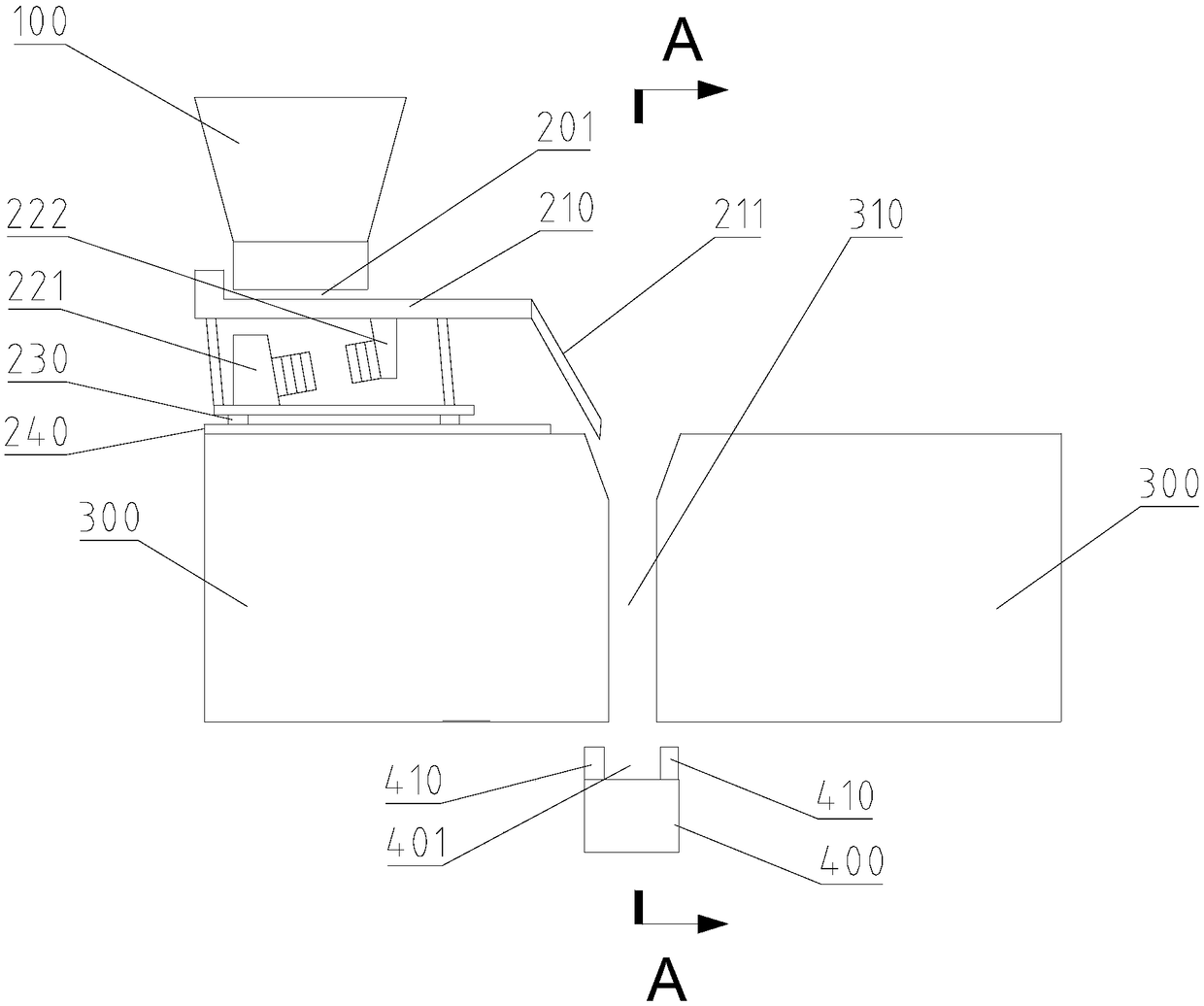

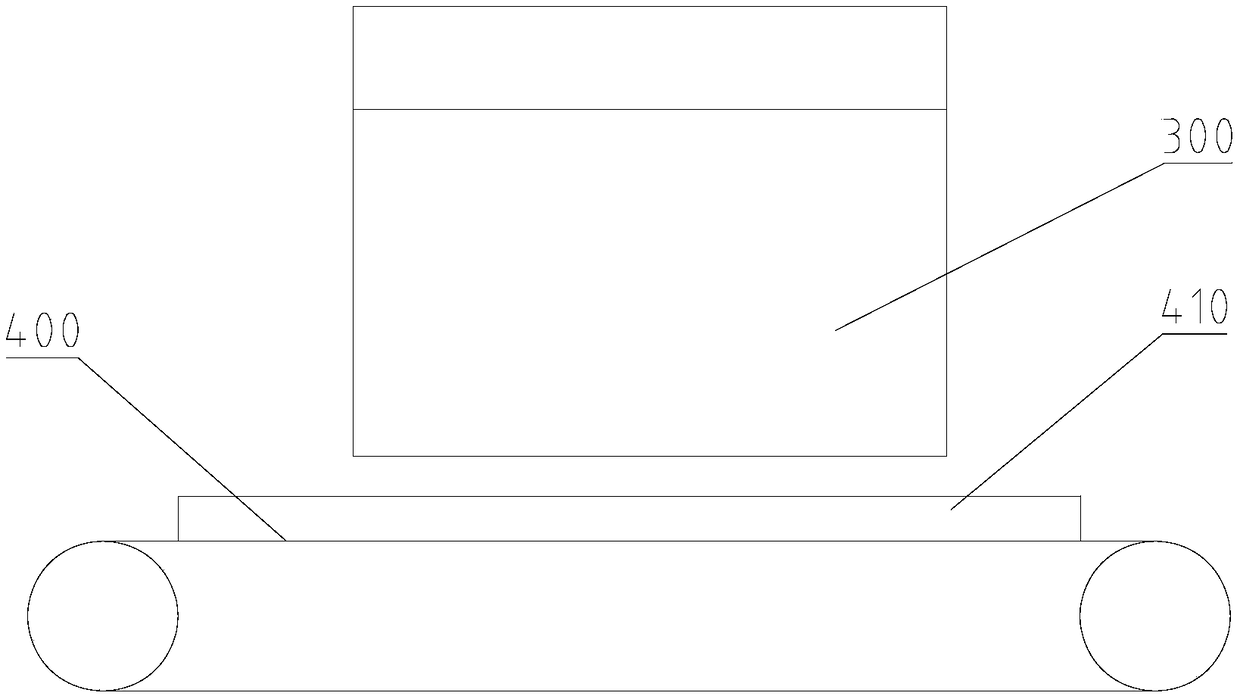

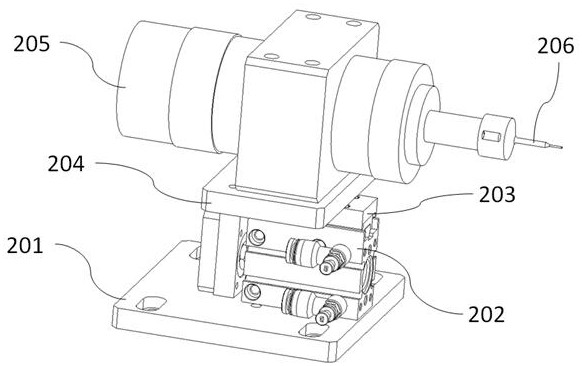

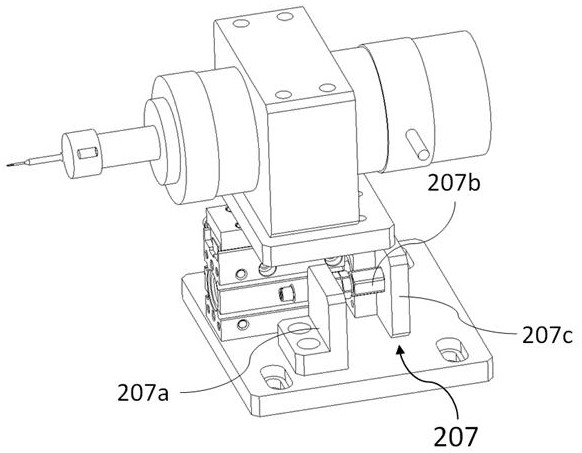

Material arranging device

PendingCN108726154AEasy to collect and transferConveyor partsEngineeringElectrical and Electronics engineering

The invention relates to a material arranging device. The material arranging device comprises a feeding mechanism, a material arranging mechanism and a discharging mechanism. The feeding mechanism isprovided with a feeding channel. The material arranging mechanism is provided with a material arranging channel and a magnetic field generating device, and the magnetic field generating device generates a magnetic field in the material arranging channel. The discharging mechanism is provided with a discharging channel. The feeding channel, the material arranging channel and the discharging channelcommunicate sequentially. Workpiece materials are automatically arranged in order, and the material arranging device is nondestructive to workpieces and high in efficiency.

Owner:佛山好运电器配件有限公司

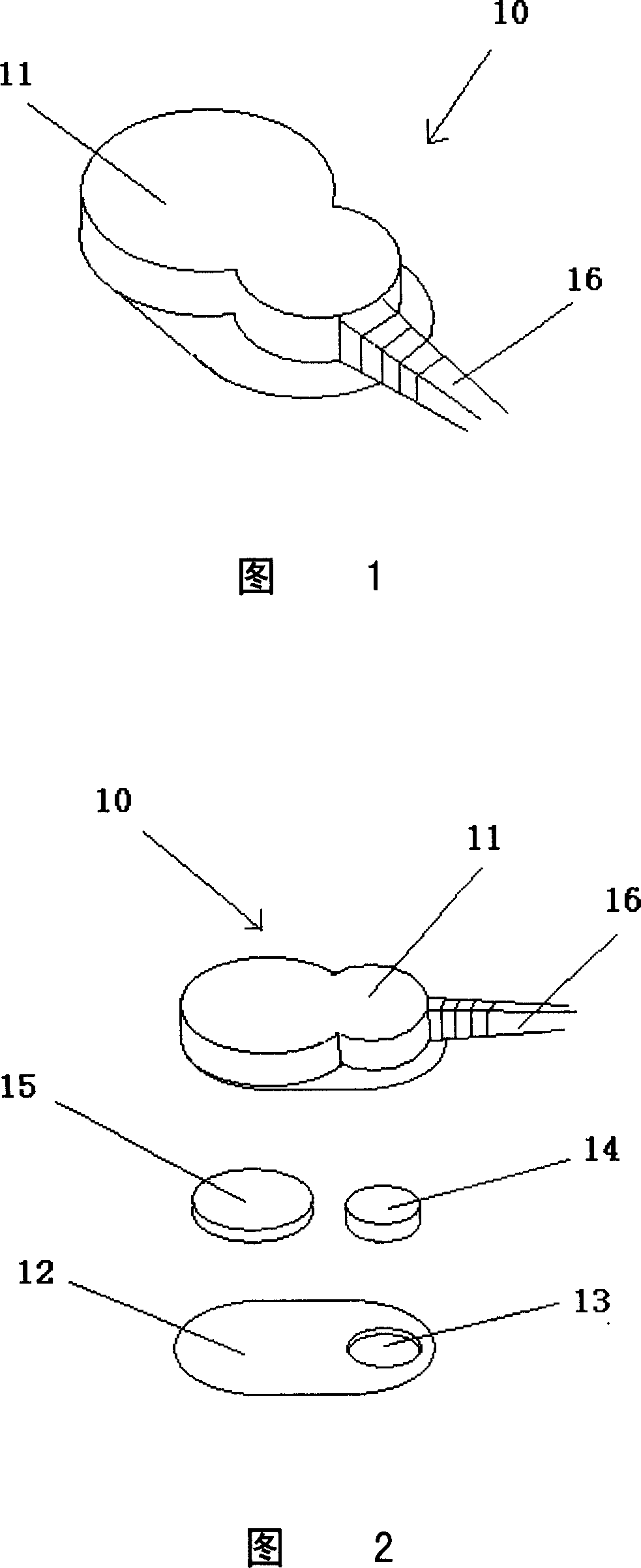

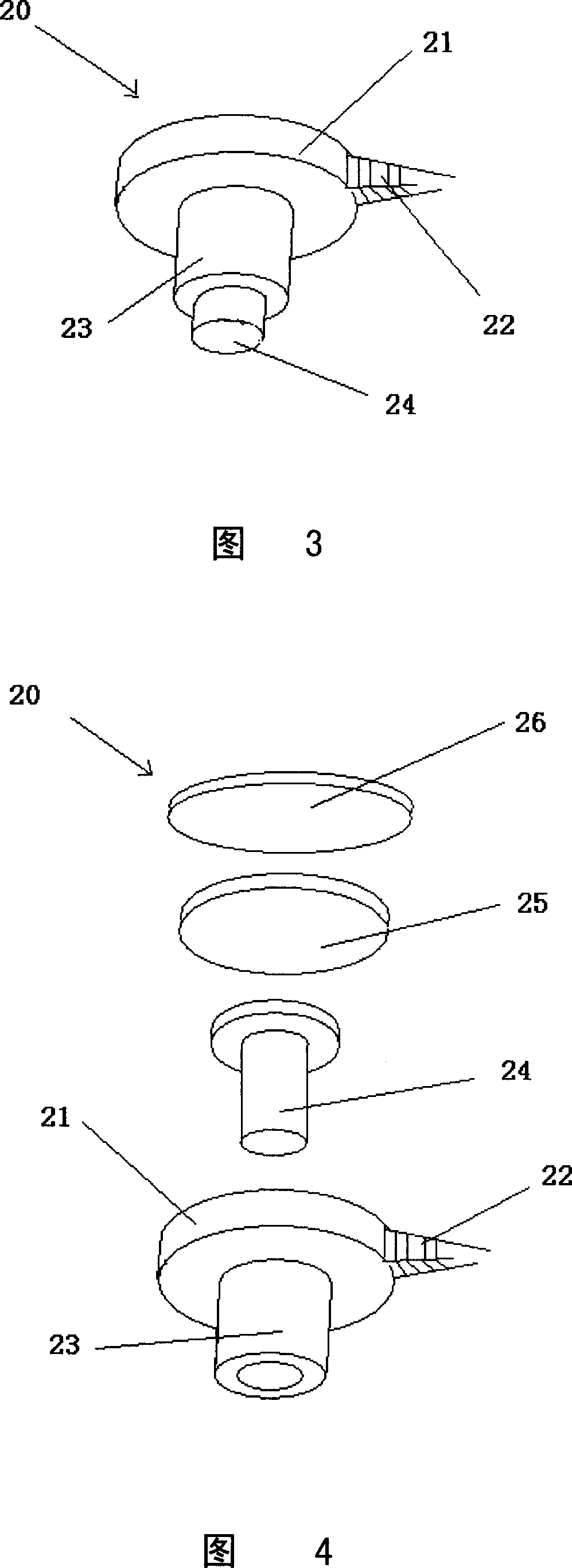

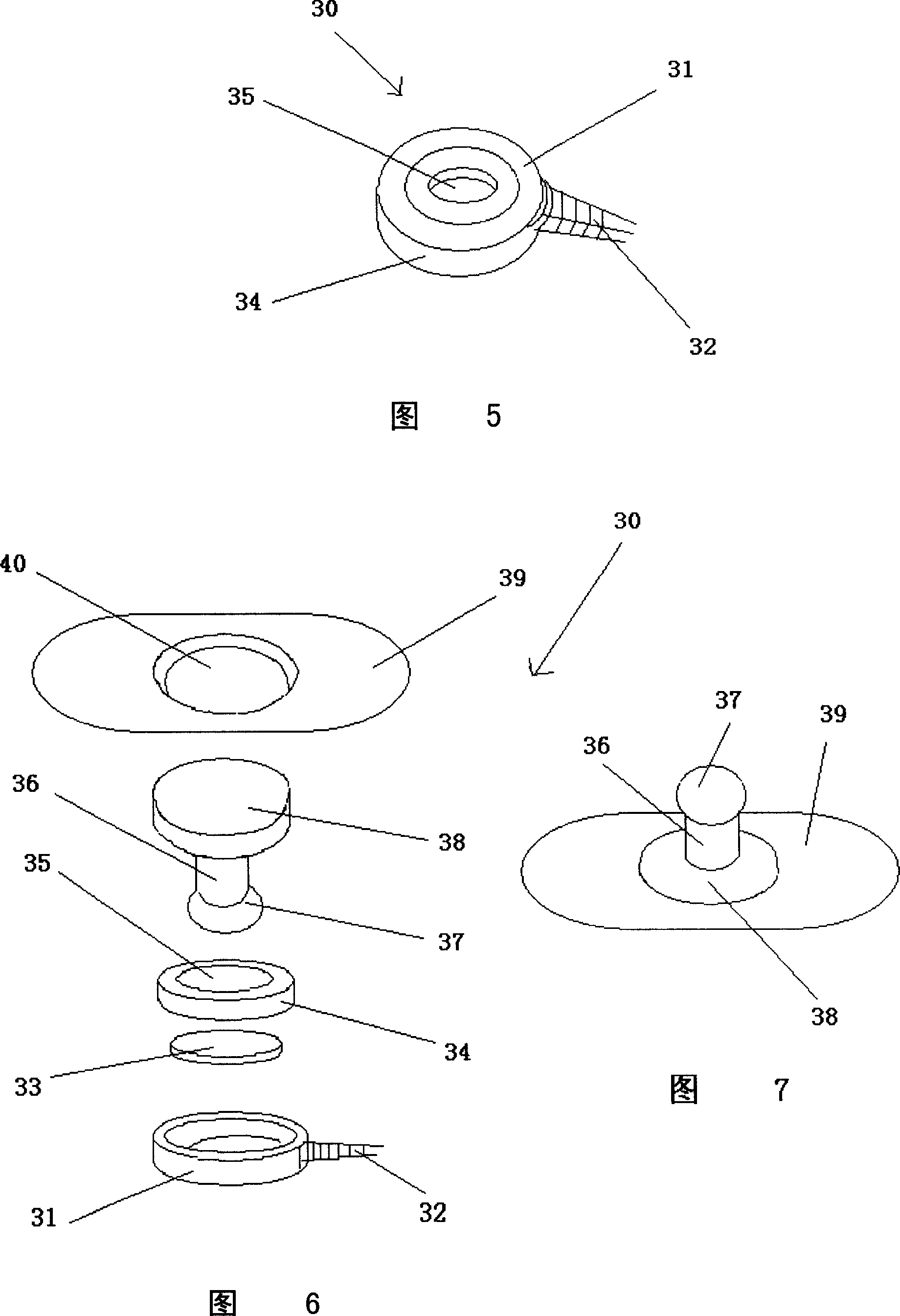

A physiological electrical signal collection device

InactiveCN1961823AReduce the interference of environmental noise on the signalEasy to collect and transferDiagnostic recording/measuringSensorsElectricityEngineering

The invention relates to a physiological signal collector, which is characterized in that: it comprises an electrode cap, a wire output connected to one side of electrode cap, an active circuit board connected to the wire output and inside the electrode cap, an electrode connected to the active circuit board and at least one end inside the electrode cap, a cover plate connected to the open end of electrode cap. The collected physiological signal is processed by forward circuit to be transmitted by wire; therefore, its signal amplitude is higher than condition interference, to reduce the skin resistance interference on the signal, while the obtained data is more accurate.

Owner:PEKING UNIV

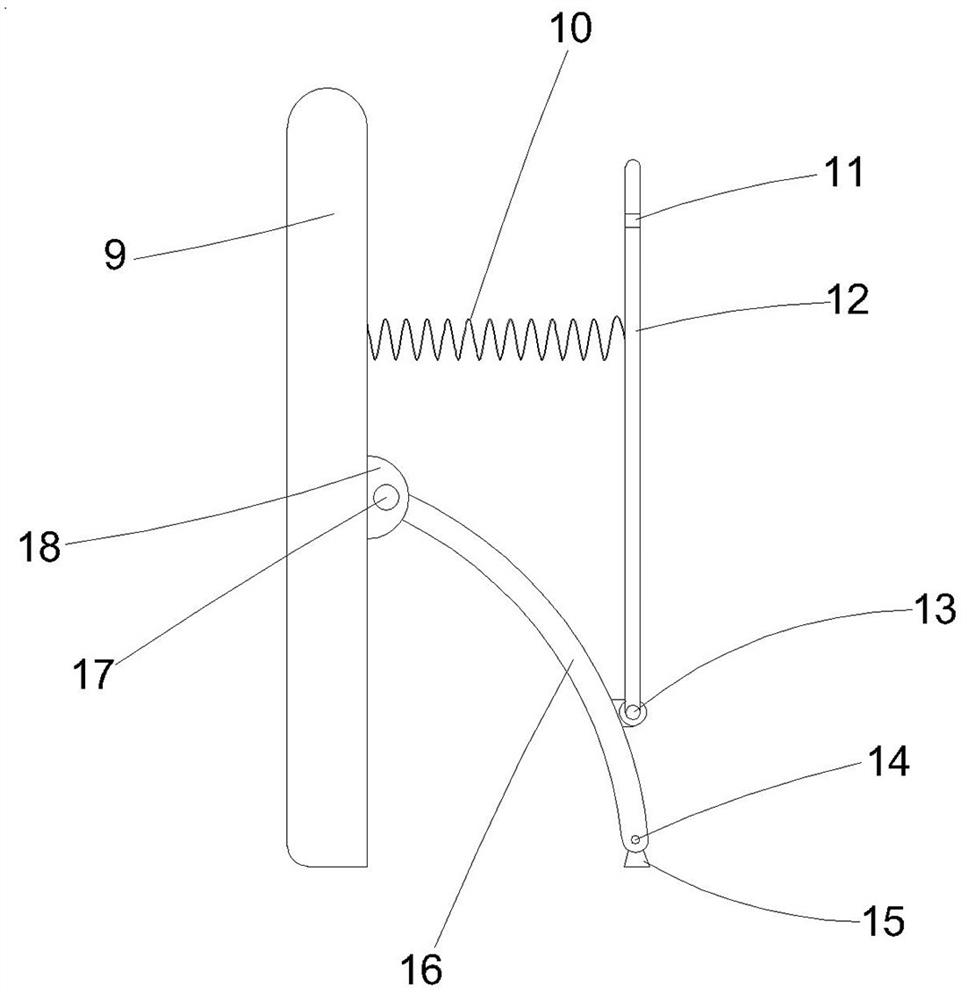

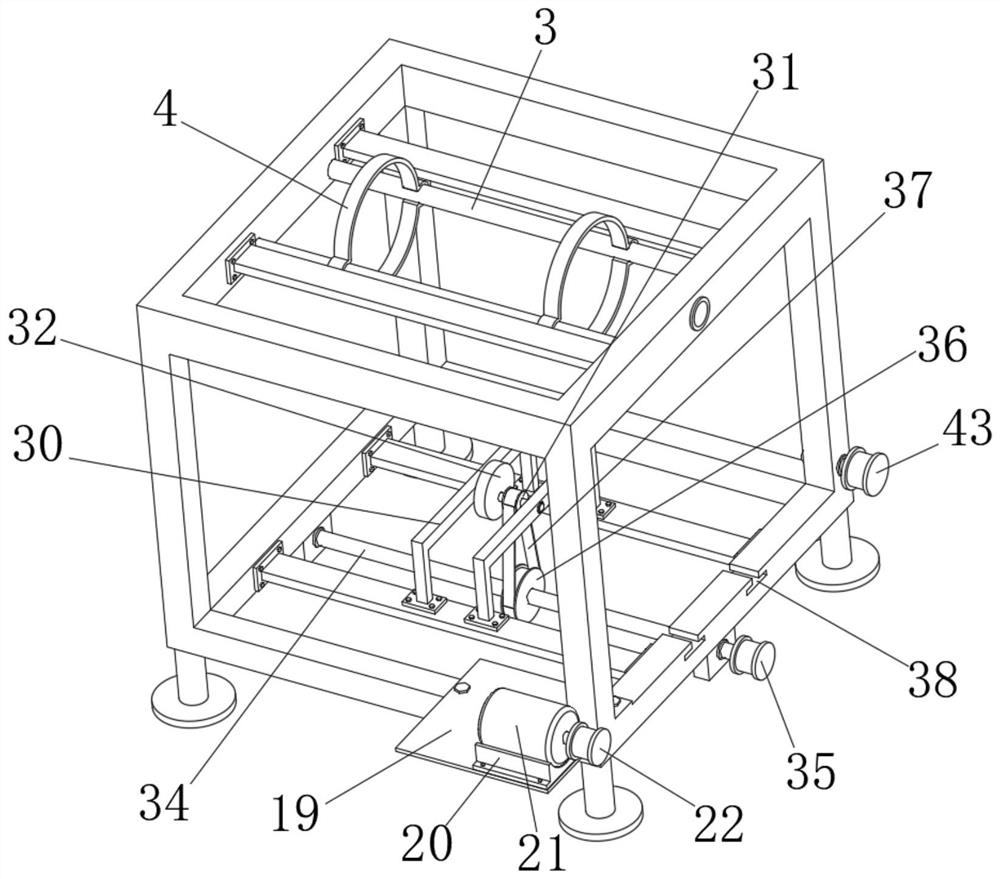

Device for rapidly preparing conductive carbon

PendingCN112691742ARealize continuous deliveryRealize installation and disassemblyHollow article cleaningGrain treatmentsEngineeringMechanical engineering

The invention relates to the field of conductive carbon preparation equipment, and particularly relates to a device for rapidly preparing conductive carbon. The device comprises a support, a conveying structure, a mounting structure, a crushing structure, an anti-blocking structure, a scraping structure, a screening structure and a collecting structure. The conveying structure is arranged at one end of the support, so that crushed carbon powder can be continuously conveyed; the mounting structure is arranged, so that a crushing assembly and the support can be mounted and dismounted, transportation and assembly are facilitated, and the damping effect can be achieved; the crushing structure is arranged, so that carbon blocks can be fully crushed, the crushing structure can drive the anti-blocking structure to work synchronously while crushing work is carried out, and therefore the position of a discharging port can be prevented from being blocked by materials; and the scraping structure is arranged in a crushing box, so that the carbon powder adhered to the interior of the crushing box can be scraped off regularly, the situation that a large amount of carbon powder is adhered to the side wall of the interior of the crushing box can be effectively avoided, and the crushing quality is guaranteed.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

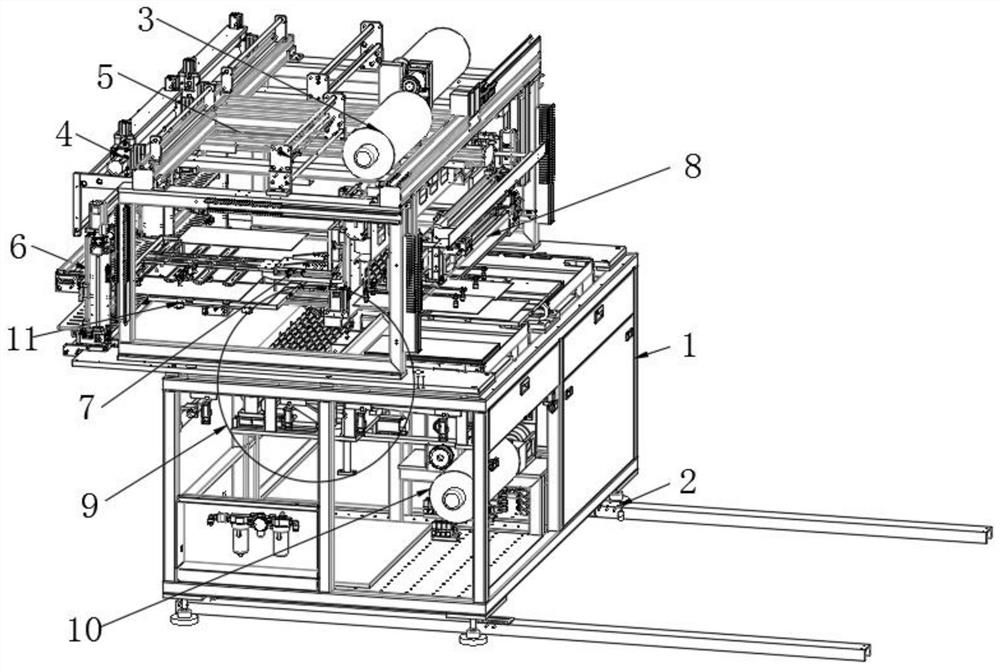

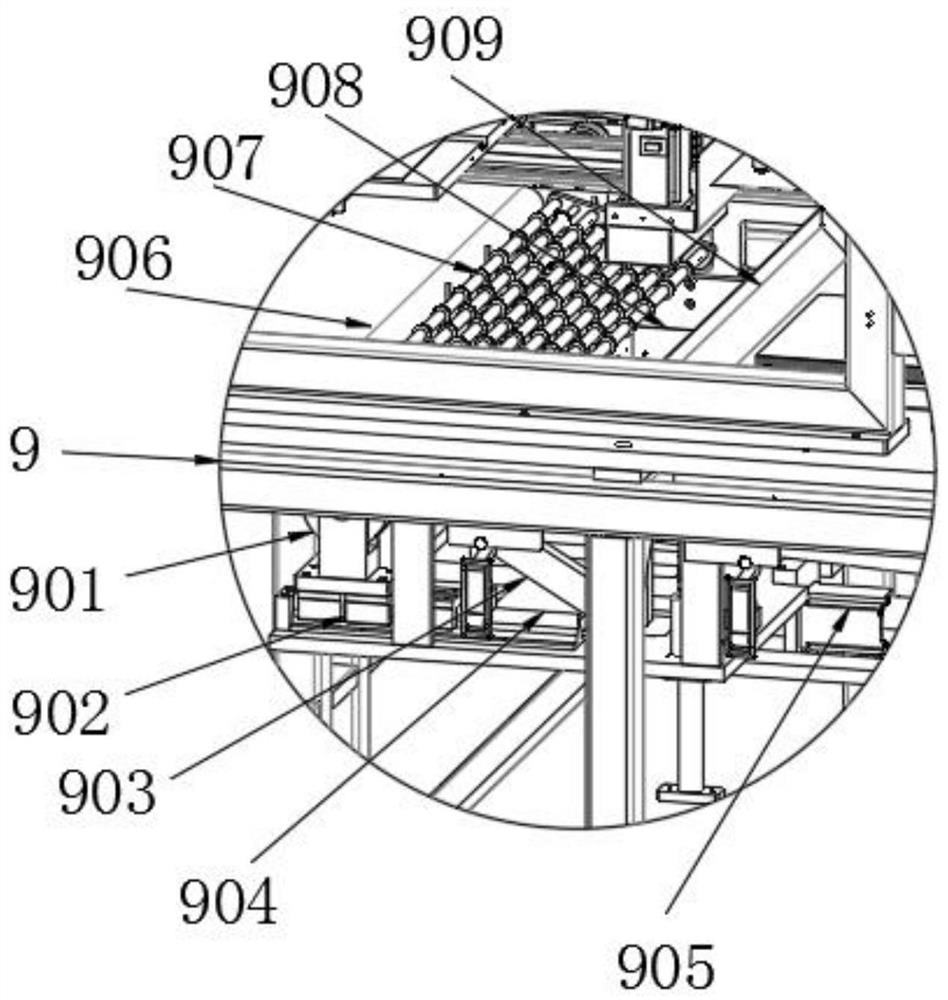

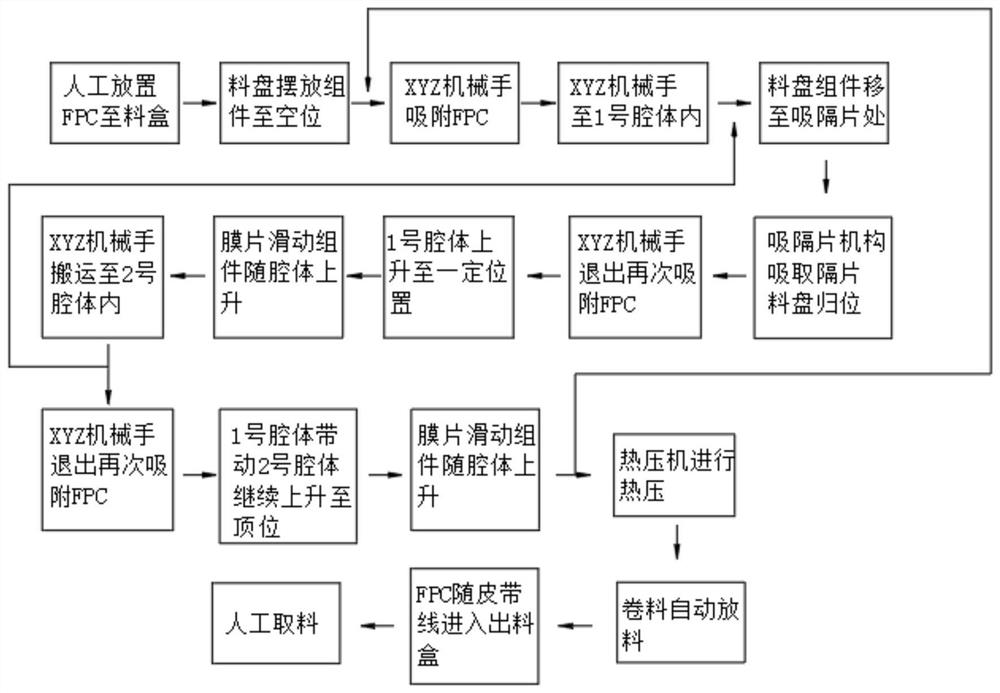

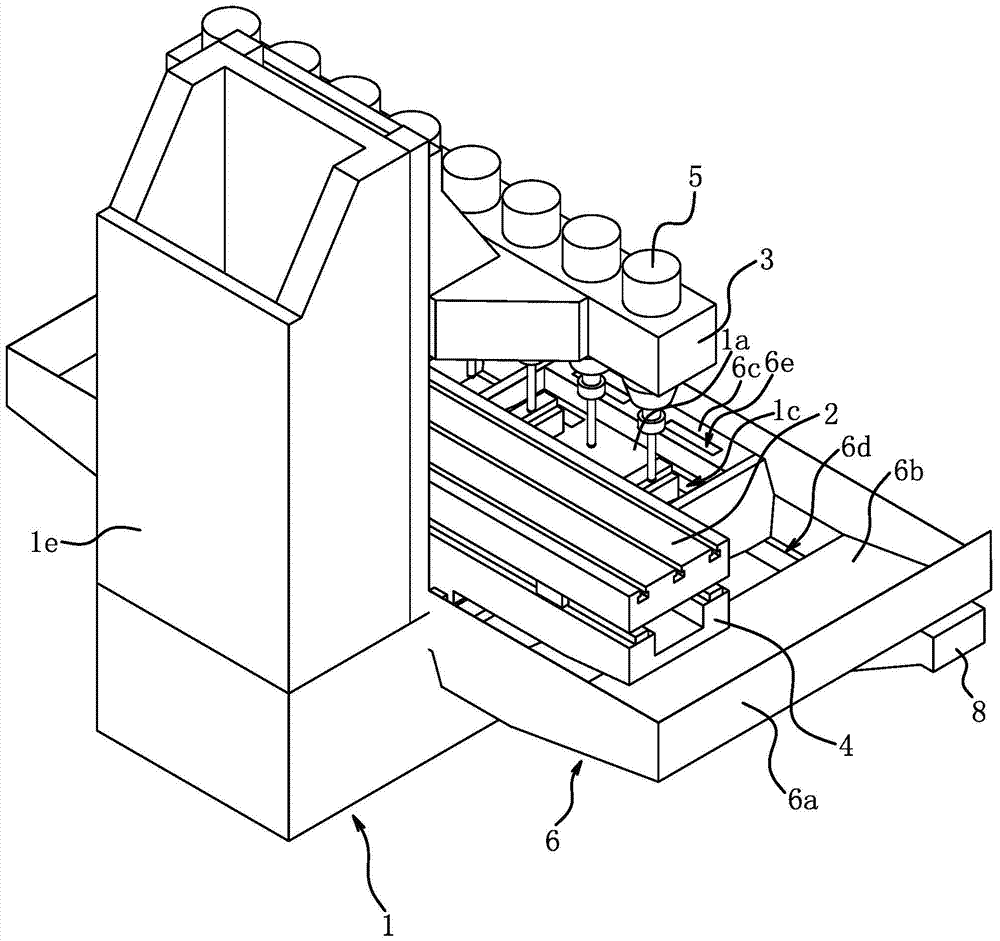

Automatic material placing machine for flexible hot-pressing process

The invention discloses an automatic material placing machine for a flexible hot-pressing process, and relates to the field of FPC production. The automatic material placing machine for the flexible hot-pressing process structurally comprises a lower frame butt-joint double-track sliding mechanism, a product sucking and carrying mechanism, a product tray bearing and moving mechanism, a release film upper-layer and lower-layer sliding mechanism, an unwinding mechanism, a winding mechanism, an upper film passing roller mechanism, a multi-position lifting belt receiving mechanism and a spacer sucking mechanism. The lower frame butt-joint double-track sliding mechanism is installed at the bottom of a lower machine frame, butt-joint for equipment during production is facilitated, the product sucking and carrying mechanism comprises a machine frame, an X-direction module, a Y-direction module, a Z-direction module, a telescopic assembly and a product suction disc, and the product tray bearing and moving mechanism comprises a bearing frame, an X-direction sliding part and a Y-direction sliding part. According to the automatic material placing machine for the flexible hot-pressing process, the use of manpower is reduced, the working environment is improved, the loss rate of product materials caused by manual errors is reduced, the automation degree is improved, and the machining efficiency is greatly increased.

Owner:深圳市福和大自动化有限公司

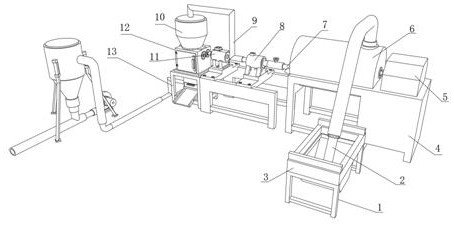

PVC ingredient particle processing device for UPVC production

The invention discloses a PVC ingredient particle processing device for UPVC production, and relates to the technical field of PVC ingredient particle processing. The PVC ingredient particle processing device is in order to solve the problem of the integrity of ingredient mixing and pelletizing and specifically comprises a first supporting frame, an installation fixed seat, a second supporting frame, a third supporting frame and a vacuum delivery pump. A powder groove is fixed to the outer wall of the top of the first supporting frame through bolts, a machine box is fixed to the outer wall ofone side of the top of the installation fixed seat through bolts, a first motor is fixed into the machine box through bolts, a mixed material box is arranged on the outer wall of the top of the installation fixed seat, a partition plate is welded on the inner wall of the periphery of the mixed material box, a material pump is fixed to the outer wall of one side of the partition plate through a bracket, a material absorbing pipe is fixed to the input end of the material pump through threads, the material absorbing pipe is inserted into the powder groove, the output end of the material pump penetrates through one side of the partition plate through a guide pipe, and a material guiding opening is formed in the outer wall of the top of the mixed material box. According to the PVC ingredient particle processing device for the UPVC production, the defect that the size of particles is different by adopting a pelletizing mode is overcome.

Owner:安徽玉发塑业有限公司

High-efficiency lubricating oil production and purification equipment

InactiveCN111575051AGood for preliminary filtrationGuaranteed purityTreatment with plural serial refining stagesLubricant compositionWaste oilVALVE PORT

The invention provides high-efficiency lubricating oil production and purification equipment. The high-efficiency lubricating oil production and purification equipment comprises a stirrer, a distiller, a heating sheet, an outer heat preservation shell, a main controller, an oil suction pump, a purifier, a cooling box, a cooling liquid injection pipe, a cooling liquid discharge valve, a waste oil discharge valve, a flow guide pipe, a lubricating oil eduction pipe and a mechanical valve. According to the invention, a crude oil purification buffer hopper, an inlet pipe and oil outlet pipe, an adsorption sheet and movable bolts, a cleaning plate, an observation window and a crude oil primary filter screen are arranged, so preliminary impurity filtering of crude oil is facilitated, and distillation effect is ensured; the crude oil is introduced into the crude oil purification buffer hopper through the inlet pipe, impurities are filtered through a crude oil primary filter screen, the filtering condition is observed through the observation window, so that cleaning can be conducted conveniently; meanwhile, iron impurities in crude oil can be adsorbed in an auxiliary mode through the adsorption sheet, so that the purity of the crude oil can be guaranteed; impurities in the crude oil primary filter screen and the crude oil purification buffer hopper can be cleaned by loosening the movable bolts and taking down the cleaning plate, the operation is convenient, and the filtering effect is guaranteed.

Owner:苑昀辉

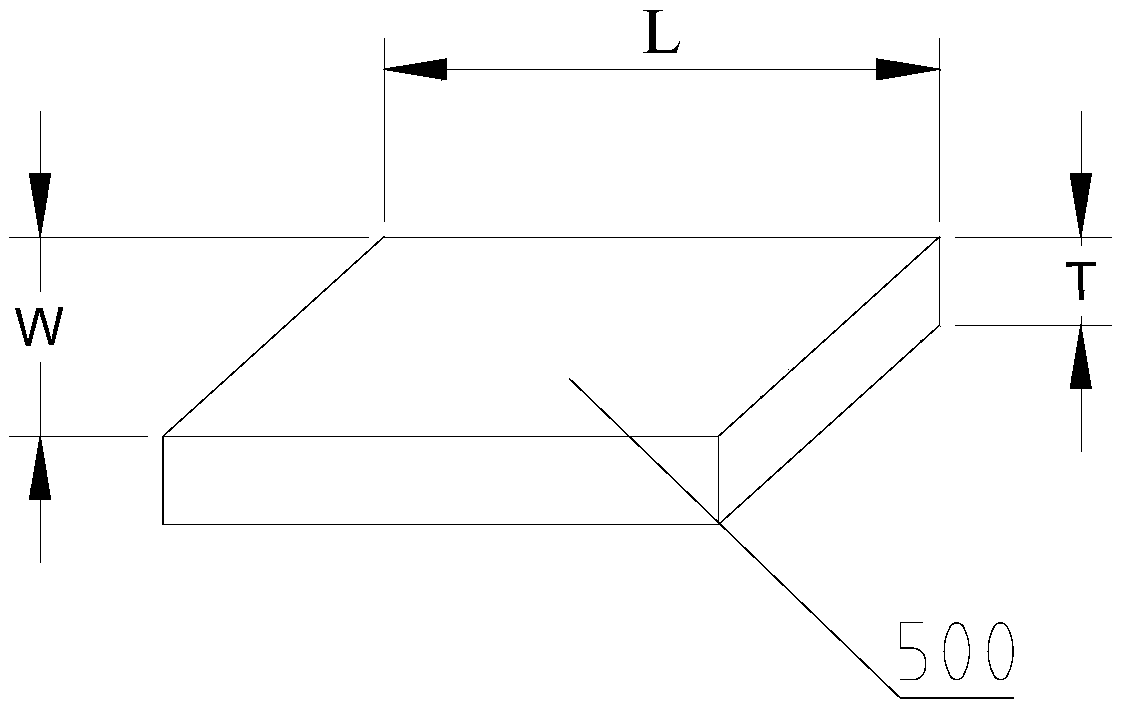

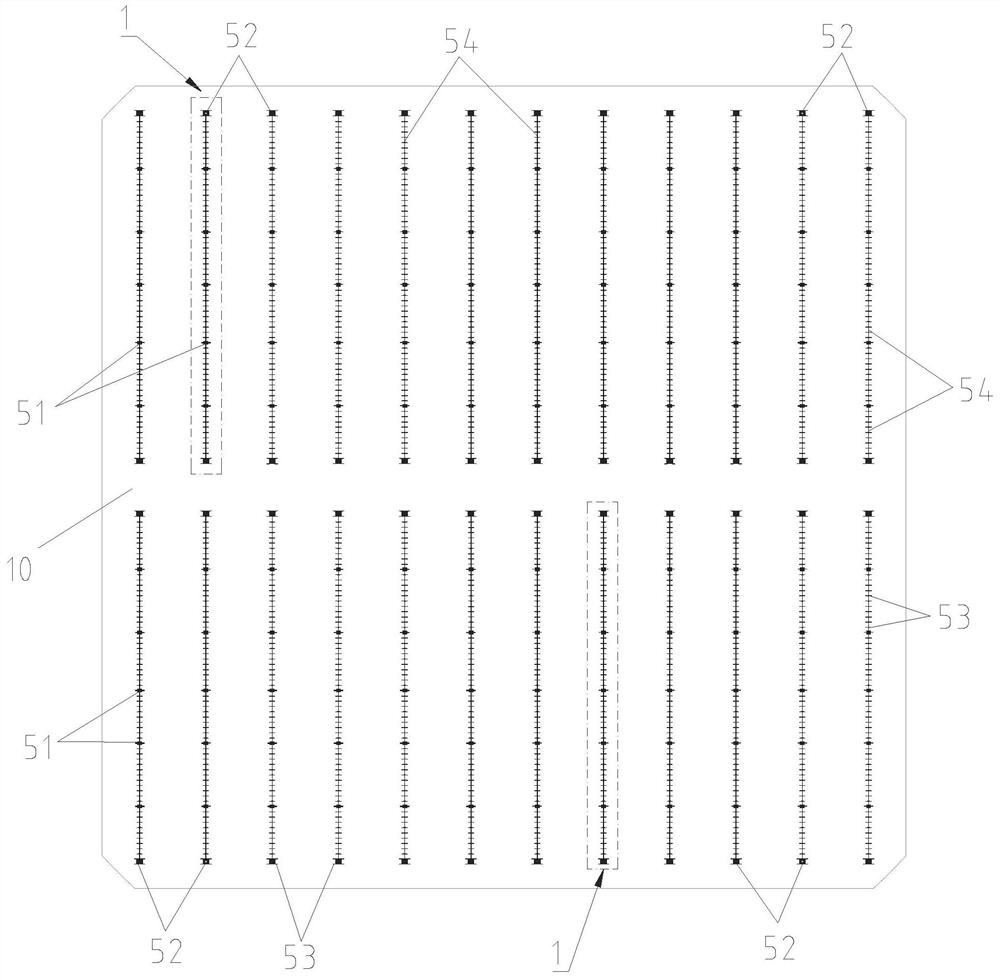

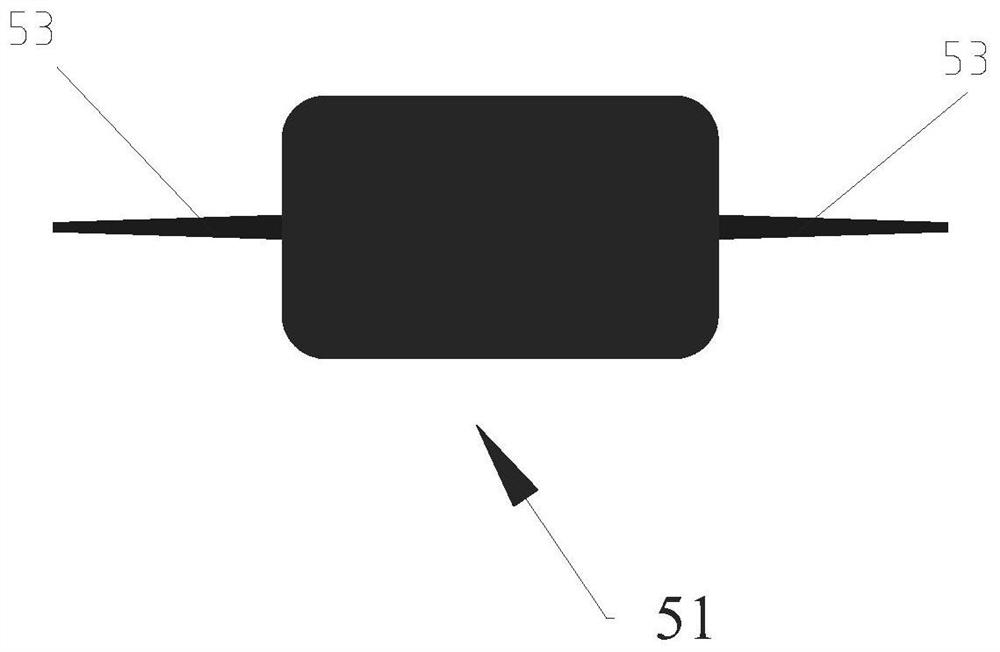

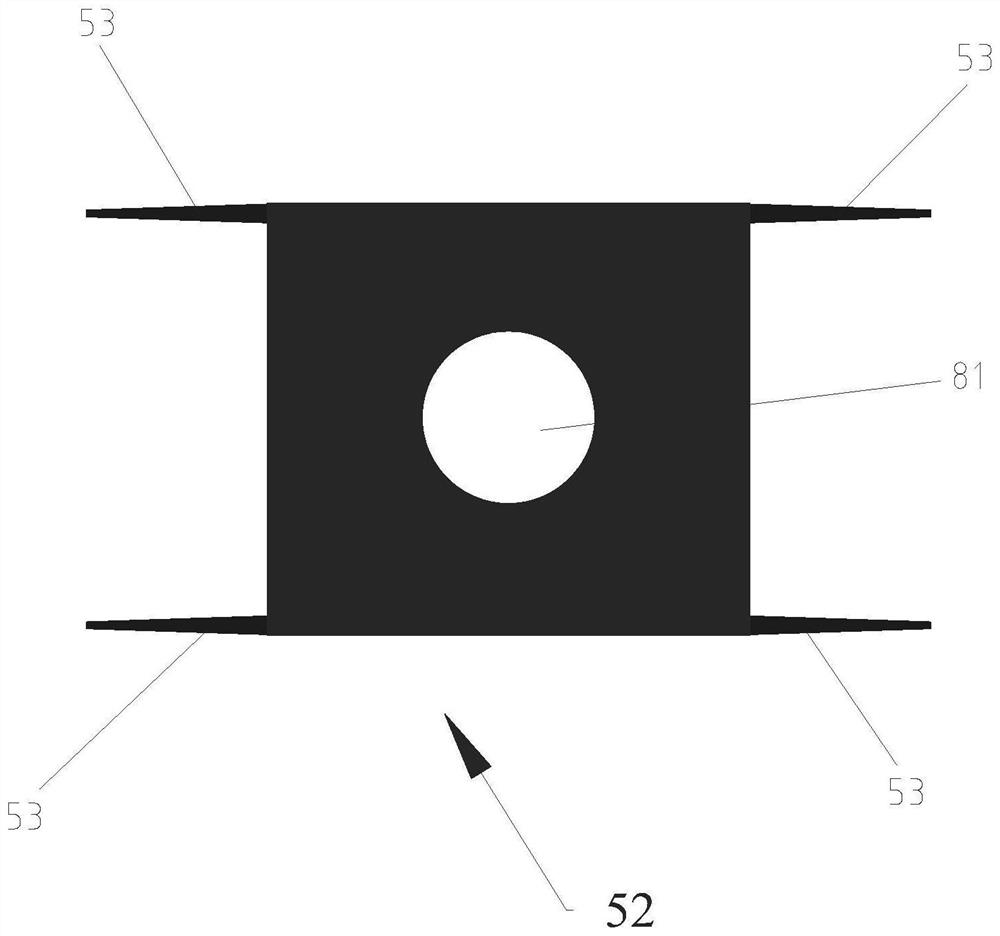

Front pattern structure of solar cell suitable for step-by-step printing and solar cell

PendingCN113345975AIncrease the transmission pathEasy to collectFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention discloses a front pattern structure of a solar cell suitable for step-by-step printing. The front pattern structure is designed on the front side of the solar cell; the front pattern structure comprises a first printing pattern and a second printing pattern; the first printing pattern comprises a plurality of main grid lines arranged in parallel; each main grid line comprises end welding pad points located at the end of the main grid line, internal welding pad points distributed between the two end welding pad points at intervals, connecting lines connected between the end welding pad points and the internal welding pad points or between the two internal welding pad points, and first connecting grids arranged on the welding pad points and the connecting lines, the extension direction of the first connecting grids is perpendicular to the extension direction of the connecting lines; the second printing pattern comprises a hollow part corresponding to the end welding pad points and a plurality of parallel auxiliary grid lines; and the first connecting grids are used for connecting the main grid lines and the auxiliary grid lines.

Owner:HANWHA SOLARONE QIDONG

In-hole deburring device

PendingCN114083748AEasy to collect and transferImprove the safety of useMetal working apparatusElectric machineWorkbench

The invention discloses an in-hole deburring device. The device comprises a rack, and a workbench is arranged at the top of the rack. In addition, two product deburring mechanisms, a product positioning jig and a rotary pressing mechanism are arranged above the workbench. Each product deburring mechanism is provided with a deburring base, a horizontal driving air cylinder, a horizontal guide block, a motor connecting block, a rotating motor and a cutter, the horizontal driving air cylinder is connected to the upper portion of the deburring base, the horizontal guide block is in driving connection with a horizontal driving motor, the motor connecting block is connected to the upper portion of the horizontal guide block, the rotating motor is connected to the upper portion of the motor connecting block, and the cutter is in driving connection with the rotating motor; the product positioning jig is arranged between the two product deburring mechanisms; and the rotary pressing mechanism is arranged on the adjacent side of the product positioning jig. With the in-hole deburring device adopted, injection molded parts can be automatically deburred, and the work efficiency of deburring is improved.

Owner:HUIZHOU ZHIJING PRECISION TECH CO LTD

Classified conveying device with insulation detection function for radar joint machining

The invention discloses a classified conveying device with an insulation detection function for radar joint machining, and relates to the technical field of radar joint processing. The classified conveying device comprises a machined part and a connecting seat, wherein a first conveying belt is arranged outside the machined part, and a placing frame is arranged at the right end of the exterior of the first conveying belt; an insulation detector is arranged in the placing frame; and a main body is arranged at the tail end of the first conveying belt. Through the arrangement of an adjusting device, when the machined part is subjected to secondary detection, a switching block can be moved in the front-back direction through the interaction of a first hydraulic air rod and an extension rod. Meanwhile, the whole adjusting device is located at the lower one-third position of the right end of the main body and can be parallel to the bottom of a fixing device, so that defective workpieces after detection can be removed through movement of the switching block in the front-back direction, and intact workpieces are reserved. Classification is simple, manual operation of a user is not needed, and use by the user is facilitated.

Owner:龙口市宝仕绝缘材料科技有限公司

A classification conveying device with insulation detection function for processing radar joints

ActiveCN112604989BConvenient and unified placementReduce gravity damageSortingRadarStructural engineering

The invention discloses a classification and conveying device with insulation detection function for radar joint processing, which relates to the technical field of radar joint processing. A placing frame is installed at the right end of the placing frame, an insulation detector is installed inside the placing frame, and a main body is installed at the end of the first conveyor belt. Through the setting of the adjustment device, the present invention can be used in the secondary inspection of the workpiece. The interaction between the first hydraulic gas rod and the extension rod moves the adapter block forward and backward. At the same time, the entire adjustment device is located in the lower third position of the right end of the main body, which can be parallel to the bottom of the fixing device, so that the adapter can pass the adapter. The movement of the front and rear positions of the block removes the processed parts that have problems after the detection, and retains the intact processed parts.

Owner:龙口市宝仕绝缘材料科技有限公司

Zinc sheet cast ingot collecting device

ActiveCN113926969AFull heating timeIngot casting process is simpleForging/hammering/pressing machinesProcess efficiency improvementIngot castingEngineering

The invention discloses a zinc sheet cast ingot collecting device which comprises a conveying mechanism, a softening mechanism, an ingot casting mechanism and a collecting mechanism. The conveying mechanism penetrates through the softening mechanism and is connected with the ingot casting mechanism, and the collecting mechanism is arranged on one side of the ingot casting mechanism; the ingot casting mechanism comprises an ingot casting machine frame, a feeding roller set, a mold assembly, an extrusion module and a discharging module; the ingot casting machine frame is arranged on one side of a discharging port of the conveying mechanism; the feeding roller set is arranged on the upper side of a conveying machine frame; the mold assembly is arranged at a discharging port of the feeding roller set; an extrusion module is arranged on the upper side of the mold assembly; and a discharging module is arranged on the lower side of the mold assembly. According to the zinc sheet cast ingot collecting device adopting the structure provided by the invention, a traditional cast ingot melting mode is mainly adopted, namely, electrolyzed zinc sheets are put into a heating furnace so as to be melted, then molten zinc is put into a mold with a specified shape and size, and zinc ingots are collected and stored in a unified mode after cooling.

Owner:桐乡市思远环保科技有限公司

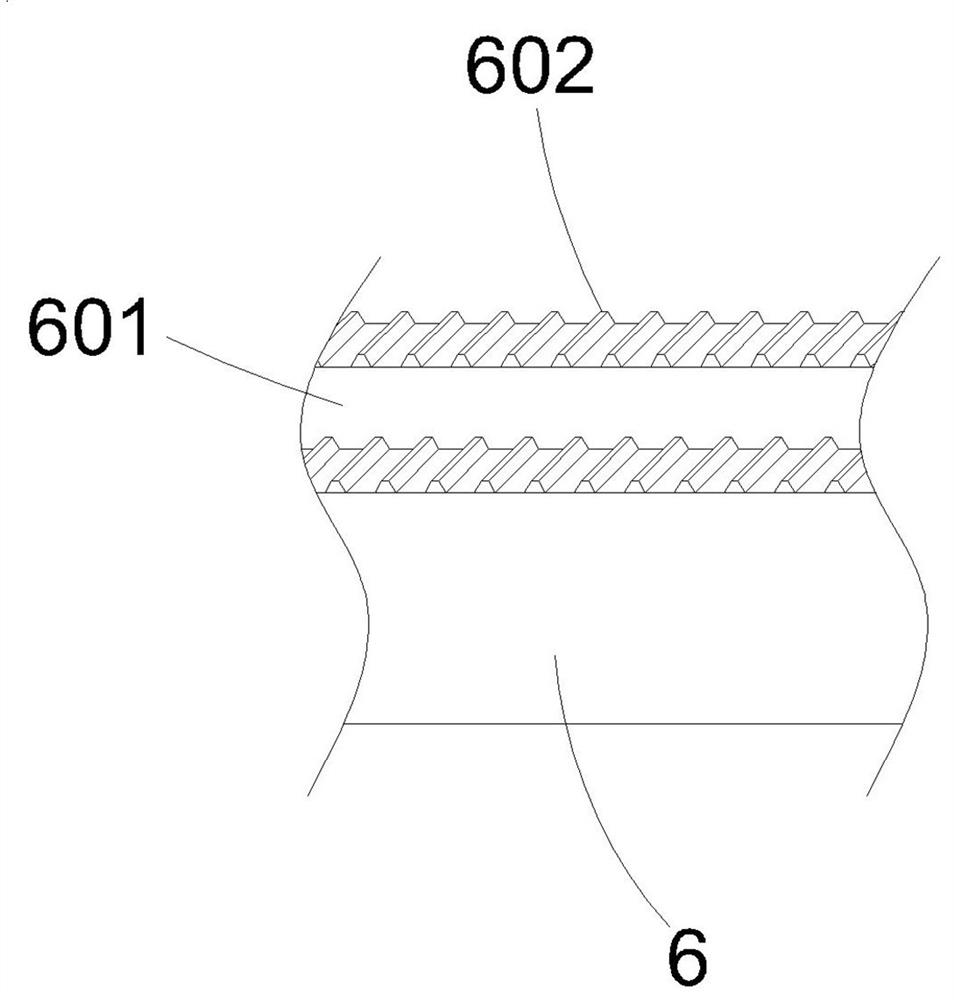

Finance and accounting paper smashing device with compacting and packaging structure

InactiveCN113499838AImprove compactionImprove crushing effectGrain treatmentsPressesStructural engineeringMechanical engineering

The invention provides a finance and accounting paper smashing device with a compacting and packaging structure, and belongs to the technical field of smashing equipment. The finance and accounting paper smashing device with the compacting and packaging structure comprises a smashing box, one side face of the smashing box is fixedly connected with a first servo motor, finance and accounting paper needing to be smashed enters the smashing box through a paper inlet, the finance and accounting paper is cut by a first smashing blade on a first fixed cutter sleeve firstly, the cut paper falls on a partition plate, and the partition plate is inclined, so that the paper subjected to primary cutting can slowly enter a second fixed cutter sleeve, is cut by a second smashing blade again and then falls into the bottom of the smashing box, a shredded paper push plate at the bottom of the smashing box can feed paper pieces subjected to secondary cutting into a connecting pipe, then the paper pieces enter a compacting box through the connecting pipe to be compacted, data can be smashed more seriously through two times of smashing, meanwhile, subsequent paper piece compaction can be more conveniently carried out, and the smashing effect is improved.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

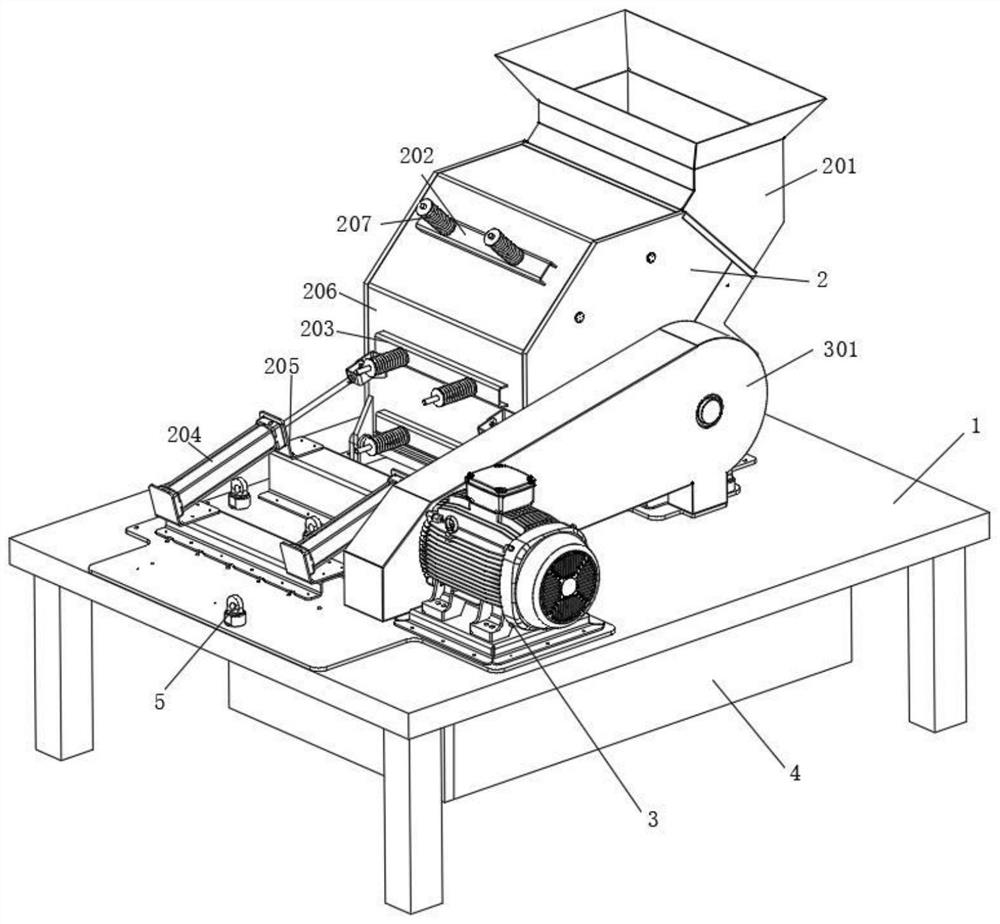

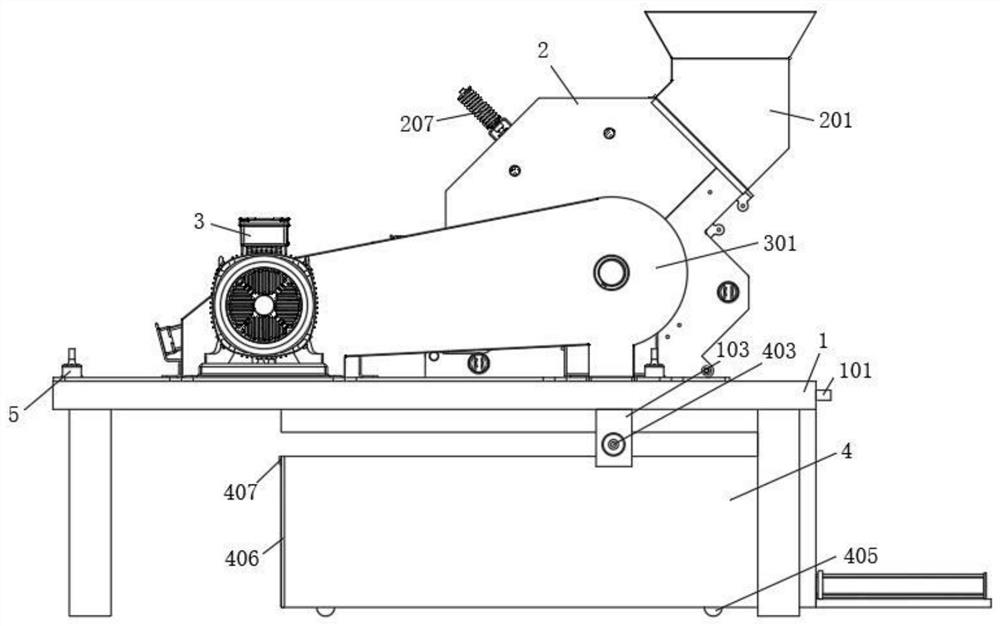

Raw material crushing and collecting device for solid red brick production

InactiveCN113877680AReduce wearing partsExtended service lifeGrain treatmentsBrickMechanical engineering

The invention discloses a raw material crushing and collecting device for solid red brick production. The raw material crushing and collecting device comprises a supporting table, the top side of the supporting table is fixedly connected with a crushing box and a motor for driving the crushing box to work, the bottom side of the supporting table is slidably connected with a material collecting box, and a cavity communicating with the crushing box and the material collecting box is formed in the supporting table; side supporting plates fixedly connected with the supporting table are arranged at the two sides of the material collecting box, an impact crushing structure is arranged in the crushing box, an auxiliary material collecting structure is arranged in the material collecting box, a transmission structure is connected between the impact crushing structure and the auxiliary material collecting structure, and a feeding hopper fixedly penetrates through the inclined upper portion of the crushing box; and a box door is rotationally hinged to one vertical side of the crushing box. By means of the raw material crushing and collecting device, raw materials are crushed in an impact type crushing mode, so that the production efficiency of solid red bricks is greatly improved, maintenance is convenient, manual pouring of the raw materials is replaced by machinery, and the workload of workers is reduced.

Owner:安庆惠嘉新型建材有限公司

Aseptic sample transfer system and method in diseased area

InactiveCN114104634AAvoid contactReduce decreaseControl devices for conveyorsChemicalsDisease areaControl engineering

The invention belongs to the field of advanced manufacturing and automation, and particularly discloses a sterile sample transfer system in a disease.The sterile sample transfer system comprises a sample transfer mechanism and a sterile regulation and control mechanism matched with the sample transfer mechanism, and the sample transfer mechanism is connected with a transfer control mechanism matched with the sterile regulation and control mechanism; the transfer control mechanism comprises a transfer control shell, an intelligent control processor is arranged in the transfer control shell, the intelligent control processor is connected with a dynamic simulation module, and a touch control screen electrically connected with the intelligent control processor is arranged on the transfer control shell; a shell fixing structure is arranged on the back of the transfer control shell.

Owner:HENAN CANCER HOSPITAL

Anti-corrosion treatment device for fan blade processing

ActiveCN113275304BReduce uncertaintyThe feeding process is stable and effectiveCompression machinesDrying gas arrangementsWater flowStructural engineering

The invention discloses an anti-corrosion treatment device for fan blade processing, comprising a water tank, a treatment box is fixed at the upper end of the water tank, a building platform is fixed at the lower part inside the treatment box, and a driving mechanism is provided at the upper end of the building platform , the peripheral outer wall of the treatment box is provided with a material inlet and a material outlet, the upper part of the inner side of the treatment box is fixed with a paint box, and the upper wall of the paint box is provided with a backflow groove. The inner wall of the tank is penetrated with a collecting tank communicating with the return tank. The advantages are: automatic loading and unloading, which reduces the uncertainty caused by manual loading, ensures the stability and effectiveness of the feeding process, and the circular processing can effectively improve the overall efficiency. The blades are cleaned by washing with water, and will not carry dust and stains Entering the next step, so as to improve the quality of the overall spraying anticorrosion treatment, the circulating flow of hot air can dry the blades sprayed with paint, which is convenient for subsequent transfer and storage.

Owner:南通清风通用机械有限公司

Scaffolding with protective function for building construction

ActiveCN111648581BEasy to fixEasy to disassembleScaffold connectionsScaffold accessoriesArchitectural engineeringScrew thread

The invention belongs to the technical field of scaffolding, in particular to a new type of scaffolding with protective function for building construction, comprising fixing brackets, the number of the fixing brackets is two, and the opposite surfaces of the two fixing brackets are fixedly connected with cards The number of said buckles is four; in the present invention, by setting threaded holes, bolts, nuts, clamping grooves and clamping rods, and loosening the bolts, the bolts are separated from the threaded caps, so that the first fixing plate and the supporting The plate is disengaged from the buckle. By lifting the guardrail, the clamping rod is released from the slot, which facilitates the disassembly of the scaffold and facilitates collection and transfer. By setting the universal wheel, it is convenient to move the scaffold. Rotate the rotating plate, so that the rotating shaft drives the threaded column to rotate, so that the slider moves in the chute, so that the threaded cylinder extends, so that the bottom plate is in contact with the ground, which is convenient for fixing the scaffold and makes the scaffold more stable when it is parked.

Owner:SHANDONG XINGANG INT TEMPLATE ENG TECH

Highway construction concrete pouring device

InactiveCN112342868AEasy to cleanSmall water absorptionRoads maintainenceStationary filtering element filtersWater storageArchitectural engineering

The invention discloses a highway construction concrete pouring device, which comprises a carrying base, a stirring tank and a box body are fixedly installed at the top of the carrying base, a feedingport is fixedly installed on the outer surface of the top of the stirring tank, and a discharging port is fixedly installed on the outer surface of the side face of the stirring tank; a transmissionshaft is fixedly installed on the side, away from the discharging port, of the stirring tank, a control panel and a faucet are fixedly installed on one side of the box body, and a water pump is fixedly installed on the side, close to the stirring tank, of the box body; filtered sewage can be conveniently collected and transferred through the water storage cavity, so that a worker can recycle waterresources in the concrete pouring process, and meanwhile, the worker can conveniently discharge and use the collected sewage through the faucet connected to one side of the water storage cavity; andtherefore, the function that workers can conveniently recycle sewage is achieved, and the practicability is greatly improved.

Owner:范标

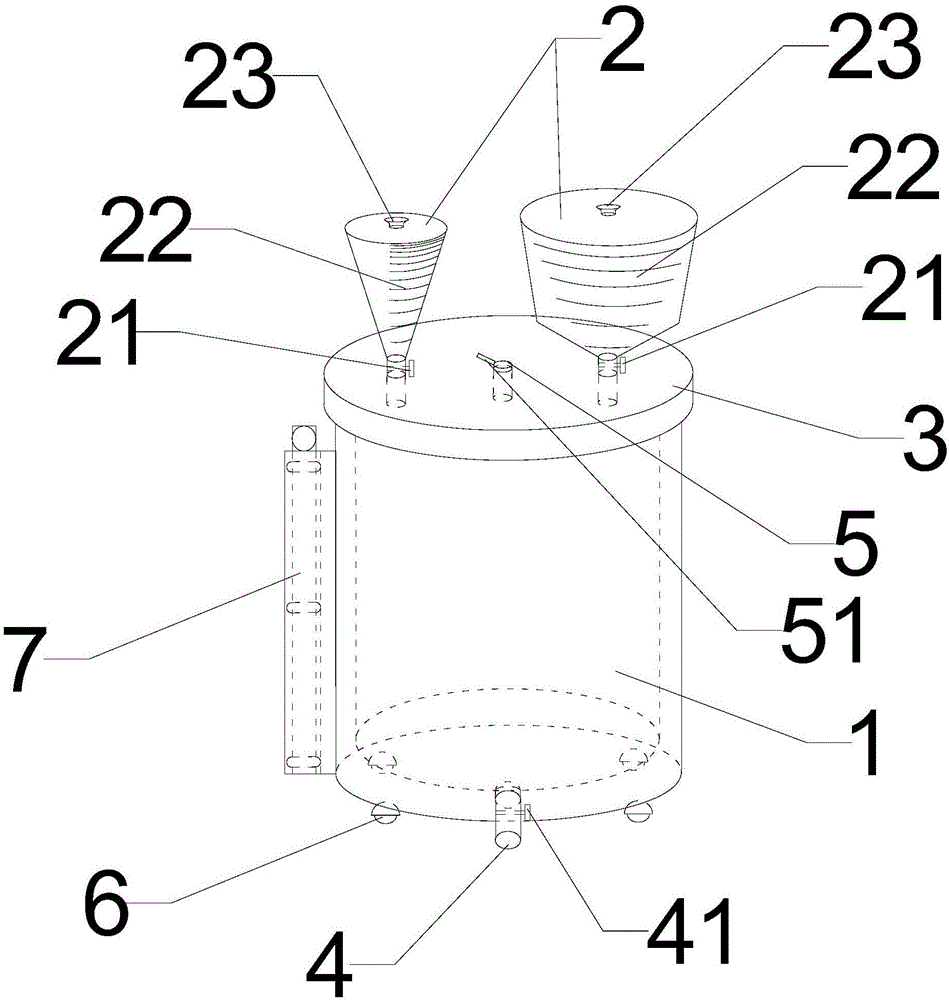

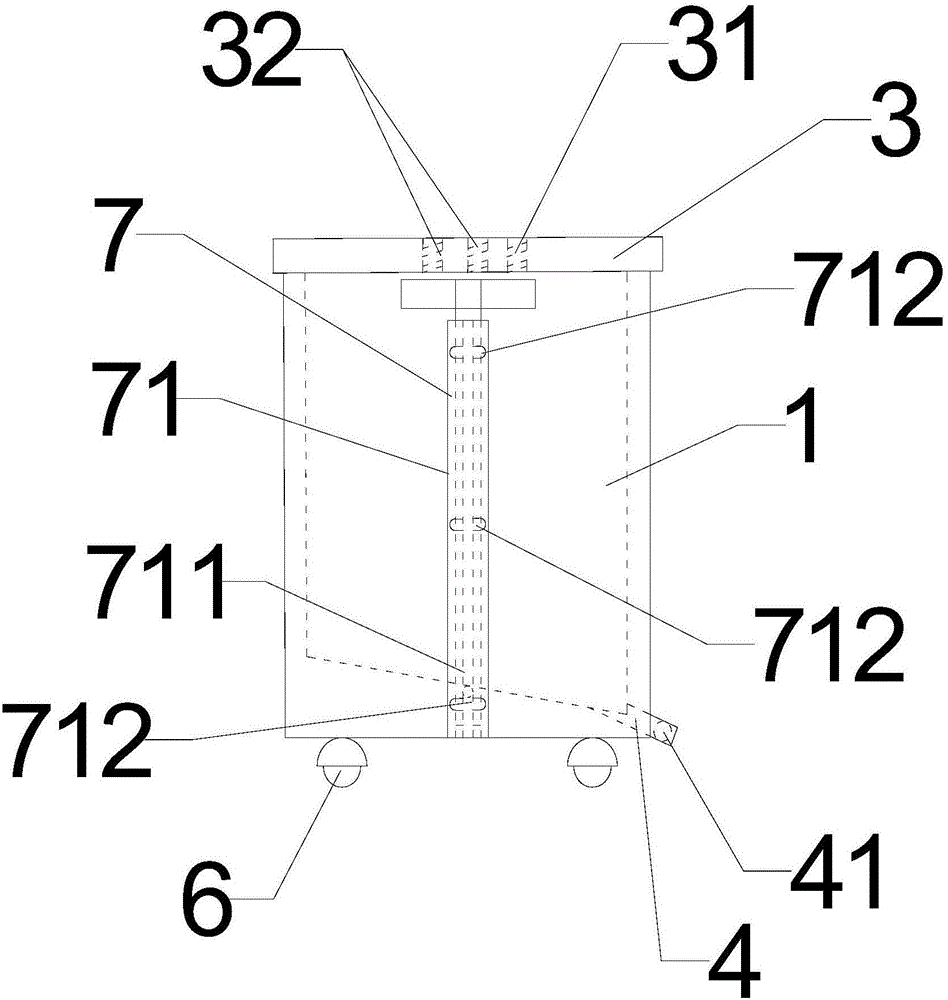

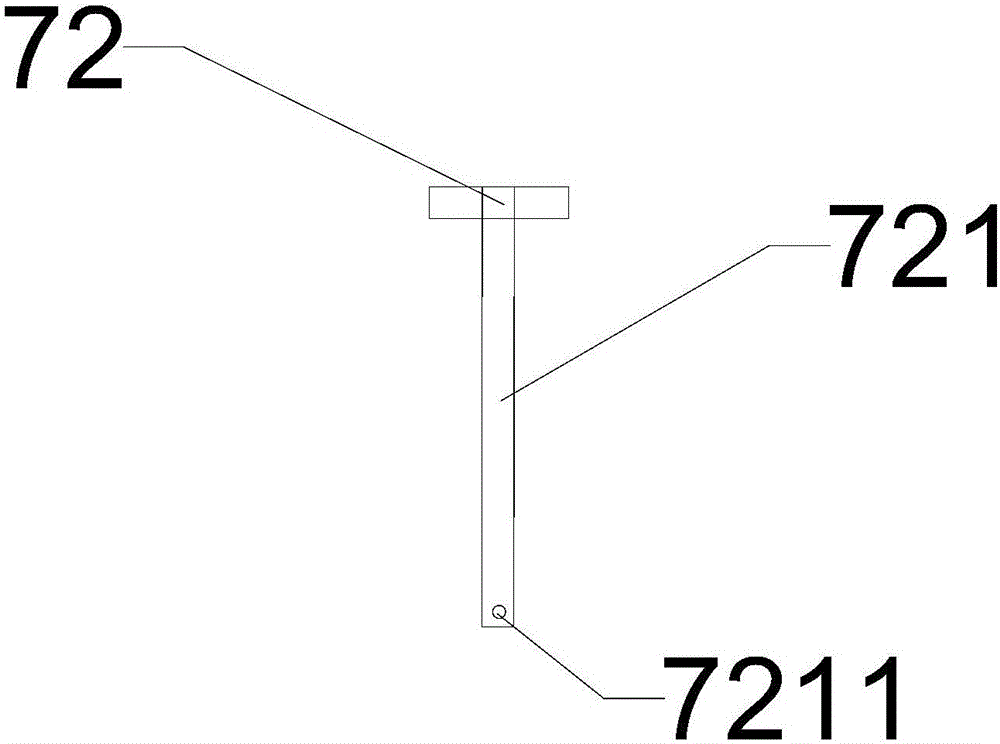

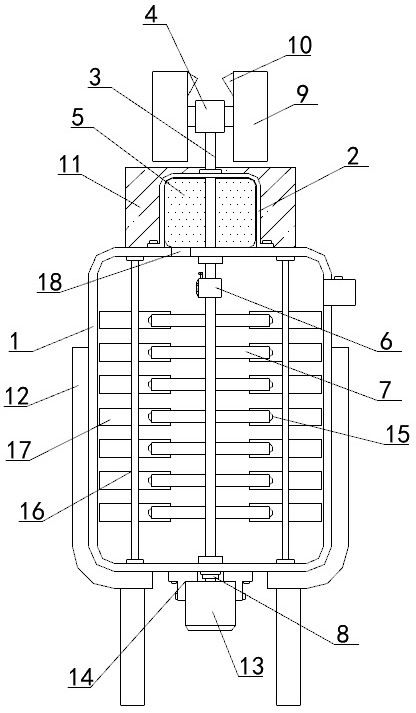

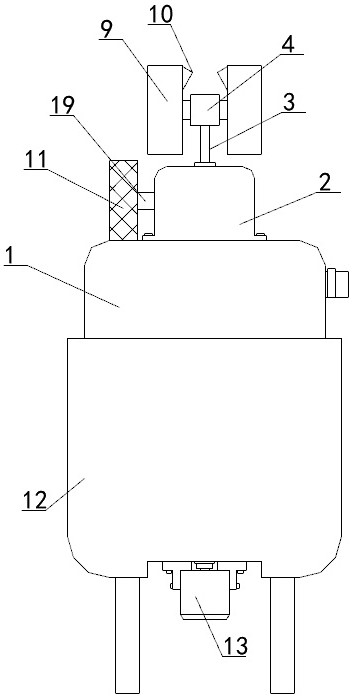

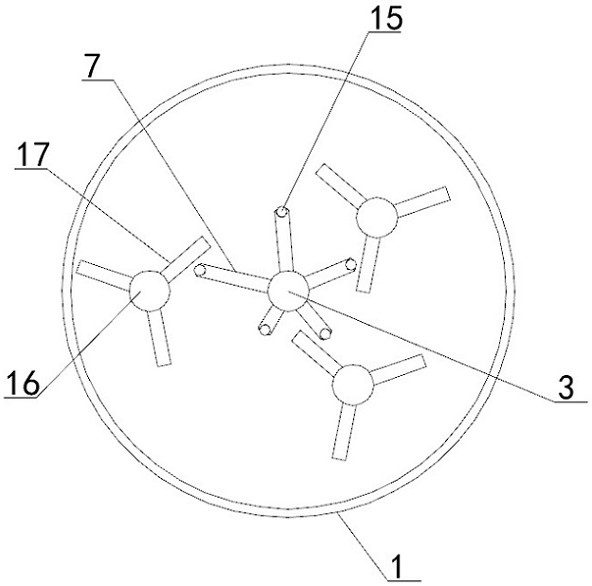

Air pressure self-discharging and self-stirring type biological fermentation tank

PendingCN114751778AIncrease the bearing areaHigh transmission efficiencyGas treatmentDispersed particle filtrationBiomaterialEngineering

The invention discloses an air pressure self-discharging and self-stirring type biological fermentation tank which comprises a tank body and an outer frame mounting structure which is a main device, a support is arranged on the outer surface of the tank body, a through cavity is formed in the top end of the tank body, and a recycling box is arranged at the top end of the through cavity; the shell is located at the middle end of the top of the tank body, a discharging pipeline is connected between the shell and the recycling box, and a throttling valve is installed in the discharging pipeline; the functional rod is located in the tank body, one end of the functional rod penetrates through the shell and the interior of the tank body, and a fixing shaft sleeve, a discharging blade, a connecting shaft sleeve, a stirring rod and a mounting shaft sleeve are sequentially arranged on the outer surface of the functional rod from top to bottom. According to the air pressure self-discharging and self-stirring type biological fermentation tank, not only can the stirring regularity in equipment be disrupted and the mixing reaction area be increased, but also a biological material can be extruded and crushed by utilizing the balls, so that the reaction effect of a biological organic fertilizer is further improved.

Owner:NANJING INST OF MEASUREMENT & TESTING TECH

Stuffing processing equipment for zongzi making and zongzi making method

InactiveCN113100270AAvoid manual processingGuaranteed qualityMeat processing devicesEngineeringRaw material

The invention relates to the technical field of zongzi stuffing processing devices, and discloses a stuffing processing device for zongzi making and a zongzi making method. Through the arrangement of a main transmission belt and the like, meat stuffing raw materials are continuously diced and fall into a cleaning frame below through a discharging hole to be processed in the next process; Therefore, a traditional manual processing mode is avoided, time and labor are saved, and safety is achieved. Through the arrangement of the water pump and the like, the cleaning of the blocked stuffing is realized, and the overall making speed of the stuffing is accelerated; through arrangement of a first belt and the like, an eccentric wheel continuously impacts a triangular block; through the synergistic effect of a plurality of overturning springs, the cleaning frame is continuously shaken; continuously shaking the meat stuffing zongzi raw materials in the cleaning frame up and down, so on the one hand, cleaning is more thorough, and on the other hand, blocky meat stuffing can slide downwards conveniently, and follow-up collection is facilitated; through the arrangement of the T-shaped groove and the like, the collecting box for collecting the meat stuffing is easy to slide, and the collected meat stuffing raw materials can be conveniently subjected to follow-up operations such as collection and transfer.

Owner:赵永岗

Multi-station vertical engraving and milling machine

ActiveCN105081781BReduce weightEasy to collectOther manufacturing equipments/toolsLarge fixed membersEngravingCornice

The invention provides a multi-station vertical engraving and milling machine and belongs to the technical field of operation. The multi-station vertical engraving and milling machine solves the problem that copper scraps in an existing engraving and milling machine are accumulated on a workbench and cannot be easily cleaned away. The multi-station vertical engraving and milling machine comprises a base, a workbench, a lifting base, a machine hood and a plurality of cutting motors. The workbench is connected with the base through a cross pulling plate with a transverse pulling plate and a longitudinal pulling plate. The front end of the base is provided with a cornice part protruding out of the front side. The outer edge of the base is provided with a strip-shaped water blocking part. The cornice part is provided with a scrap falling hole. The machine hood is provided scrap guiding funnel parts which are located below the two ends of the transverse plugging plate and each in the shape of a funnel, and the scrap guiding funnel parts of the machine hood are fixed to the top face of the water blocking part. According to the multi-station vertical engraving and milling machine, the scrap guiding funnel parts of the machine hood are arranged on the two sides to collect cutting bits, the machine hood is a sheet metal part and small in weight, and therefore the situation that the weight of the engraving and milling machine is too large is effectively avoided, and the engraving and milling machine is suitable for being disassembled and assembled through a common loading machine.

Owner:陈美青

Mixing-type lime kiln capable of quickly cooling and discharging

The invention relates to the field of lime production, in particular to a mixing-type lime kiln capable of quickly cooling and discharging. The mixing-type lime kiln comprises a kiln body, wherein a partition plate is arranged in the kiln body, the partition plate is provided with a plurality of through holes used for allowing a finished lime product to pass through, the partition plate is arranged on the lower side of a fire grate, a cooling cavity is formed between the fire grate and the partition plate, a collecting cavity is formed in the lower side of the partition plate, an air outlet pipe is arranged on the side wall of the cooling cavity, an air supplying device is connected to the air outlet pipe, thus the finished lime product falling from the fire grate into the cooling cavity is cooled through air input by the air outlet pipe, the temperature of the finished lime product falling into the collecting cavity is decreased quickly, the finished lime product is collected, transferred and used conveniently, and workers are also prevented from being scalded by the high-temperature finished lime product; and meanwhile, air guided into the upper part of the fire grate is heated by the finished lime product, dispersed by the fire grate and can evenly enter raw materials on the upper part of the fire grate, normal and even burning of fuel on the upper part of the fire grate ismaintained conveniently, conducting of the calcination process is promoted, and the calcination time is reduced.

Owner:四川马氏窑技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com