Waste lithium battery electrolyte treatment system and treatment process thereof

A waste lithium battery and processing system technology, applied in the field of waste lithium battery treatment, can solve the problems of inconvenient waste battery classification, transfer and collection, inability to externally clean waste batteries, and increase workload, etc. Easy to collect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

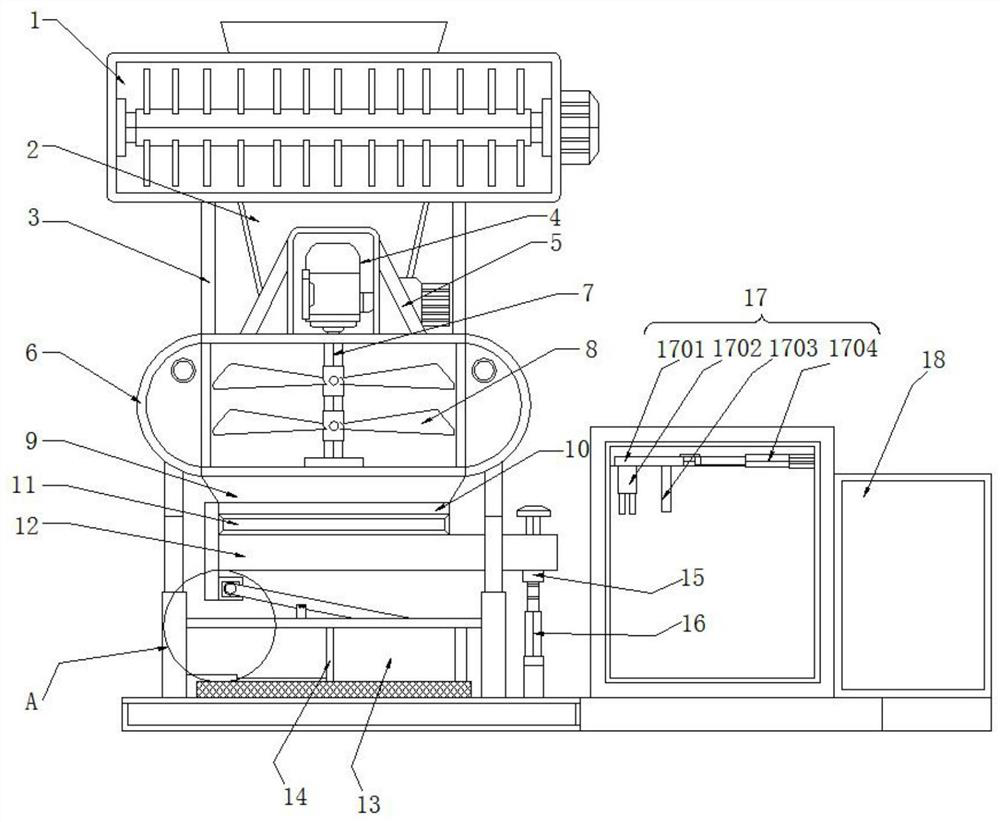

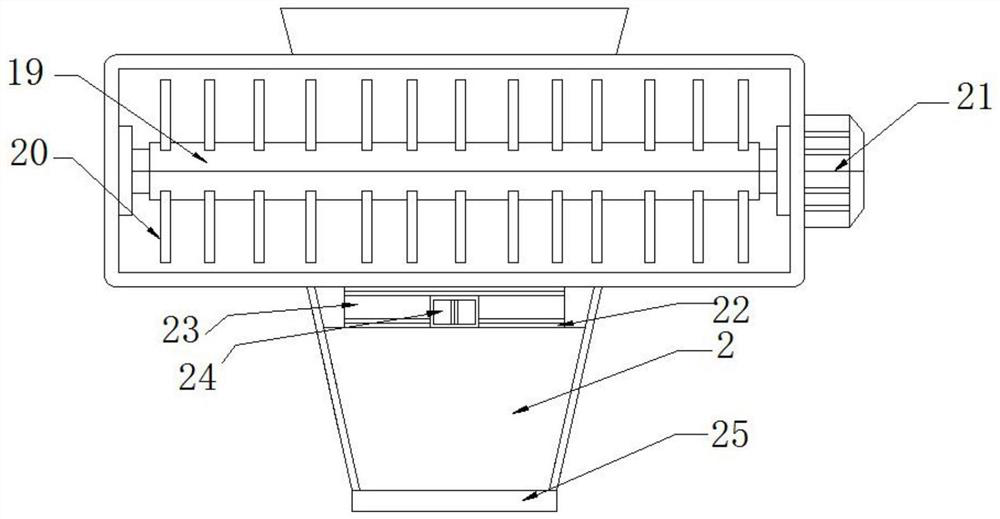

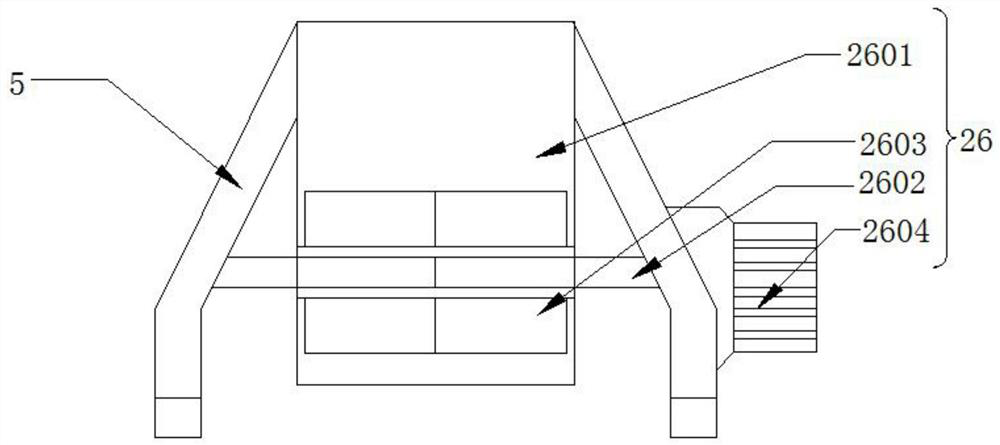

[0031] see Figure 1 to Figure 5, the present invention provides a technical solution: a waste lithium battery electrolyte treatment system and its treatment process, including a first processing frame 1, a guide belt 2, a support frame 3, a first motor 4, a stabilizing frame 5, and a second processing frame 6 , rotating shaft 7, crushing blade 8, feeding port 9, leak port 10, baffle 11, screen 12, first storage chamber 13, connecting plate 14, adapter block 15, first hydraulic air rod 16, cleaning assembly 17 , horizontal plate 1701, cleaning brush 1702, push plate 1703, second hydraulic air rod 1704, second storage chamber 18, horizontal axis 19, vertical strip 20, second motor 21, bottom opening 22, barrier plate 23, the second Three hydraulic air rods 24, positioning magnetic plate 25, auxiliary components 26, built-in cavity 2601, connecting shaft 2602, adsorption guide plate 2603, third motor 2604, side cavity 27, connecting port 28, pipeline 29, water pump 30, electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com