Coil transposition wire-curved tool and use method

A tool and wire bending technology, applied in the field of coil transposition bending tools, can solve problems such as easily damaged wire paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0019] see Figure 1-4 , a coil transposition bending tool, which includes a first bending tool and a second bending tool.

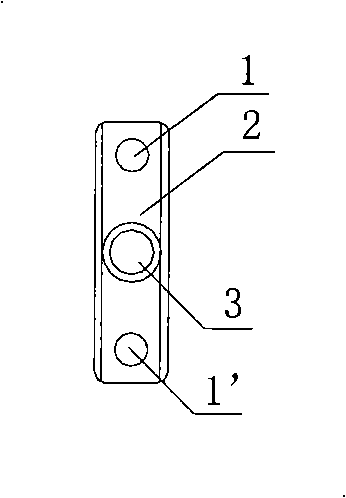

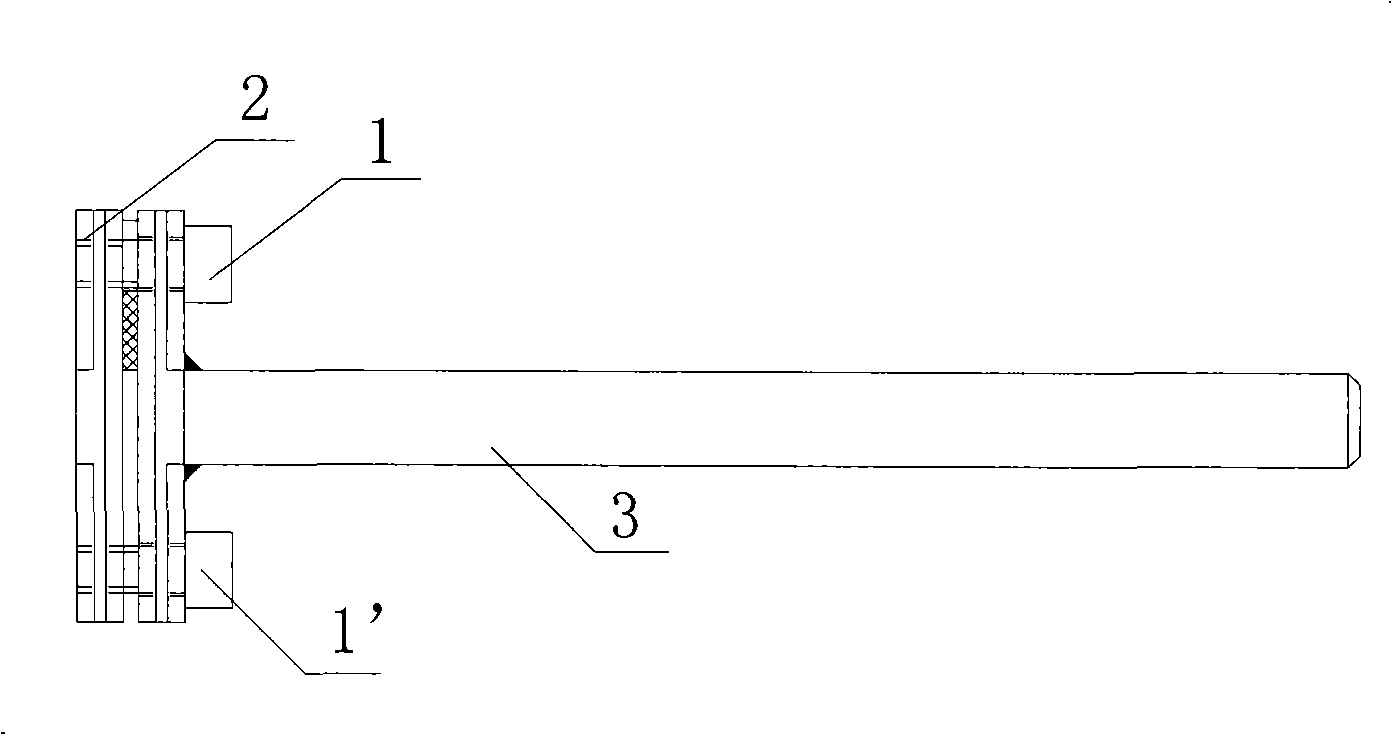

[0020] The first wire bending tool includes a cuboid head 2 made up of two cuboid metal blocks of the same size and a rod-shaped handle 3 vertically connected to one of the head metal blocks, each of the two ends of the two metal blocks has a Screw holes, they can be detachably combined by screws 1 and 1'; the upper and lower long sides of the cuboid metal block of the head are all inverted at an angle of 45 degrees to the short side of the side.

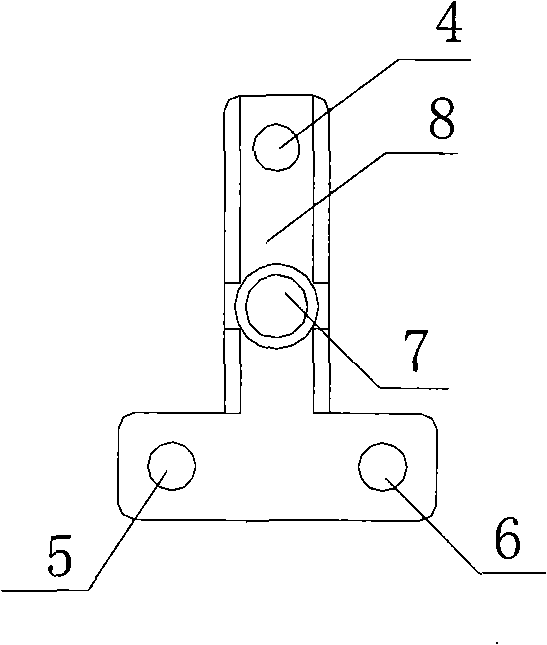

[0021] The second wire bending tool includes a T-shaped head 8 made up of two T-shaped metal blocks of the same size and a rod-shaped handle 7 that is vertically connected to one of the T-shaped metal blocks of the head. Each of the three free ends of the block has a screw hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com