Aerosol dust falling system

An aerosol and dust reduction technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of equipment not working properly, unsatisfactory dust reduction effect, and insufficient spraying of water mist, etc., to avoid accumulation Water freezing, good water saving performance, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

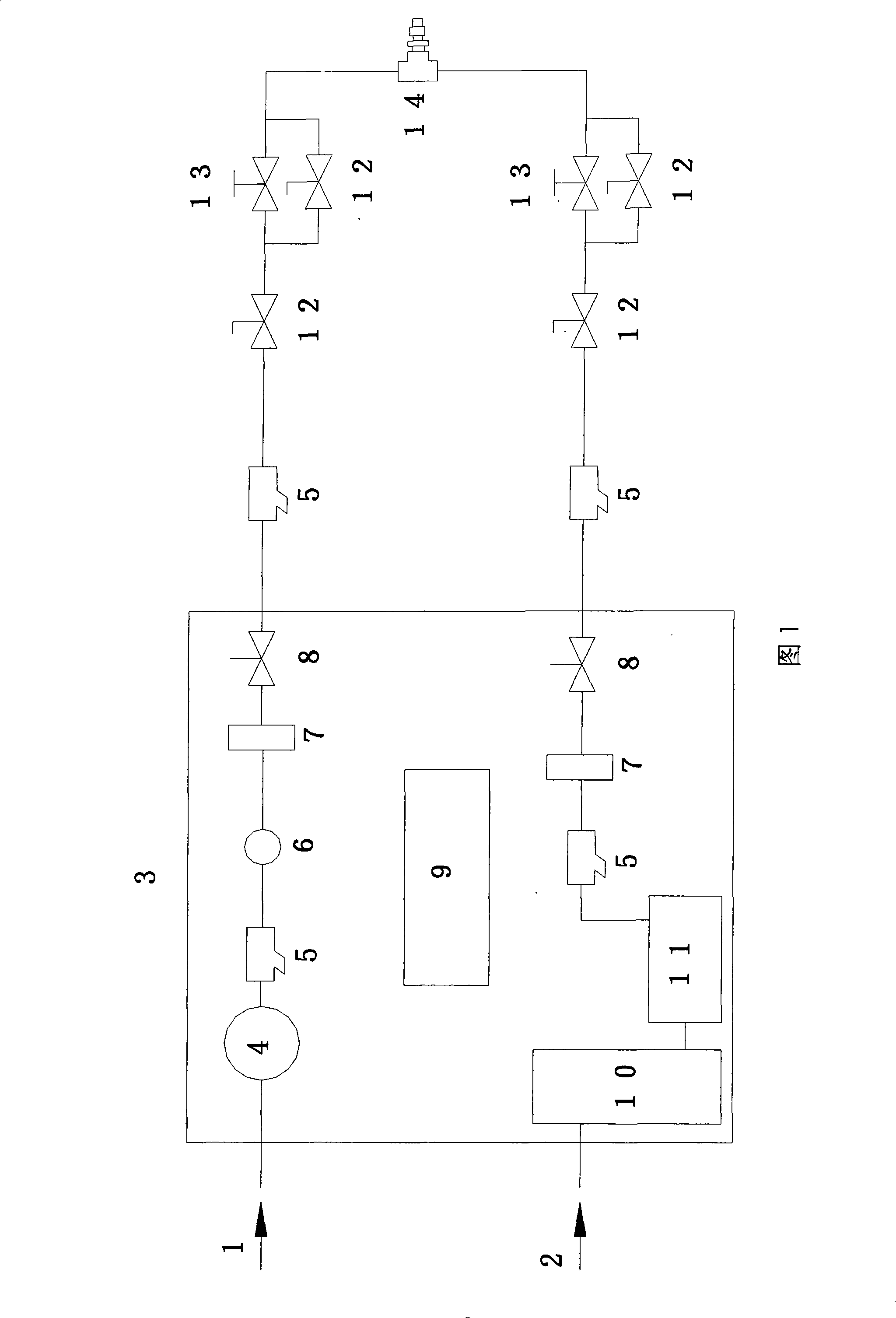

[0026] As shown in FIG. 1 , the system of the present invention includes an aerosol control box 3 and its external pipeline system and a spray device 14 , which have functions such as pressurization, pressure regulation, and filtration. The aerosol control box 3 includes a control system 9, a liquid control unit and a gas control unit; the external piping system includes a liquid pipeline and a gas pipeline, and the spray device 14 is located at the end of the liquid pipeline and the gas pipeline. pool.

[0027] The liquid control unit is composed of a water pump 4 , a filter valve 5 , an electric node pressure gauge 6 , a pressure regulator 7 , and a one-way valve 8 .

[0028] The gas control unit is composed of an air compressor 10, an air storage tank 11, a filter va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com