Preparation method of low carbon low silicon no-aluminum half-technique non oriented electrical steel

A technology of oriented electrical steel, low-carbon and low-silicon, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increasing production costs, and achieve the goals of reduced production costs, excellent magnetic properties of finished products, and optimized annealing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

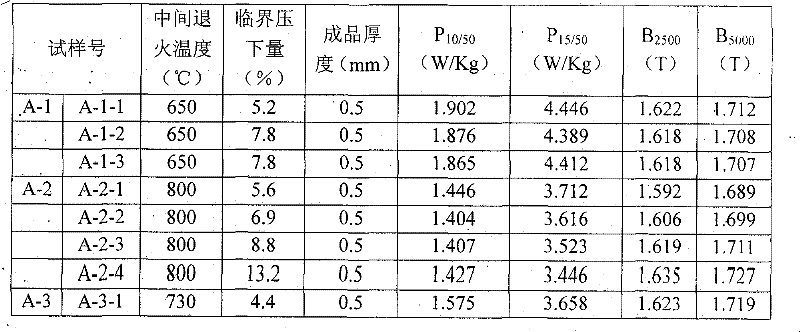

[0016] The chemical composition (%) of steel A continuous casting slab is shown in Table 1.

[0017] Table 1 Chemical composition (%) of continuous casting slab of steel A

[0018] Sample No.

C

Si

mn

P

S

N

O

the remaining

A

0.002

1.03

0.26

<0.005

0.006

0.0046

0.01

Fe and unavoidable impurities

[0019] The thickness of the hot-rolled steel strip is 2.3mm. The air-cooled hot-rolled steel strip is pickled and then cold-rolled. After intermediate annealing at 650-800°C for 1-2min, the annealing atmosphere is required to be 30%H 2 +70%N 2 Mixed gas does not require humidification and decarburization, and it is necessary to ensure that the crystallization rate after intermediate annealing is ≥ 40%. Then undergo critical deformation cold rolling with a reduction rate of 4.4-13.2%, and the hardness of the steel plate after critical deformation cold-rolling is 130-180HV. ...

Embodiment 2

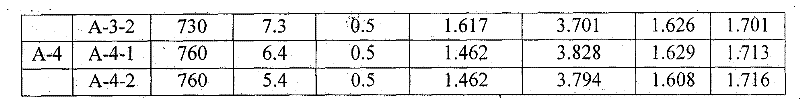

[0024] The chemical composition (%) of steel B continuous casting slab is shown in Table 3.

[0025] Table 3 Chemical composition (%) of steel B continuous casting slab

[0026] Sample No.

C

Si

mn

P

S

N

O

the remaining

B

0.002

0.45

0.29

0.062

0.005

0.0039

0.012

Fe and unavoidable impurities

[0027] The thickness of the hot-rolled steel strip is 2.3mm. The air-cooled hot-rolled steel strip is pickled and then cold-rolled. After intermediate annealing at 650-800°C for 1-2min, the annealing atmosphere is required to be 30%H 2 +70%N 2 Mixed gas does not require humidification and decarburization, and it is necessary to ensure that the crystallization rate after intermediate annealing is ≥ 40%. Then undergo critical deformation cold rolling with a reduction rate of 3.1-8.4%, and the hardness of the steel plate after critical deformation cold rolling is 130-180HV. Af...

Embodiment 3

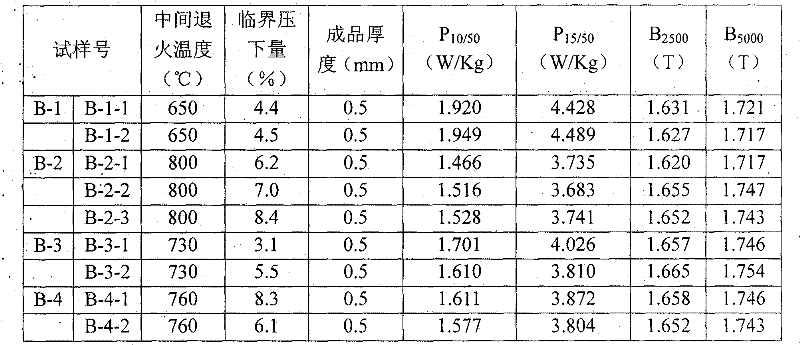

[0031] The chemical composition (%) of steel C continuous casting slab is shown in Table 5.

[0032] Table 5 Chemical composition (%) of steel C continuous casting slab

[0033] Sample No.

C

Si

mn

P

S

N

O

the remaining

C

0.002

0.74

0.28

0.065

0.006

0.0033

0.012

Fe and unavoidable impurities

[0034] The thickness of the hot-rolled steel strip is 2.3mm. The air-cooled hot-rolled steel strip is pickled and then cold-rolled. After intermediate annealing at 650-800°C for 1-2min, the annealing atmosphere is required to be 30%H 2 +70%N 2 Mixed gas does not require humidification and decarburization, and it is necessary to ensure that the crystallization rate after intermediate annealing is ≥ 40%. Then undergo critical deformation cold rolling with a reduction rate of 3.7-10.7%, and the hardness of the steel plate after critical deformation cold ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com