Portable type pipe electric bevelling machine

A beveling machine and portable technology, which is applied to pipe cutting devices, metal processing machinery parts, feeding devices, etc., can solve the problems of time-consuming and labor-intensive, cumbersome construction cost, huge equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

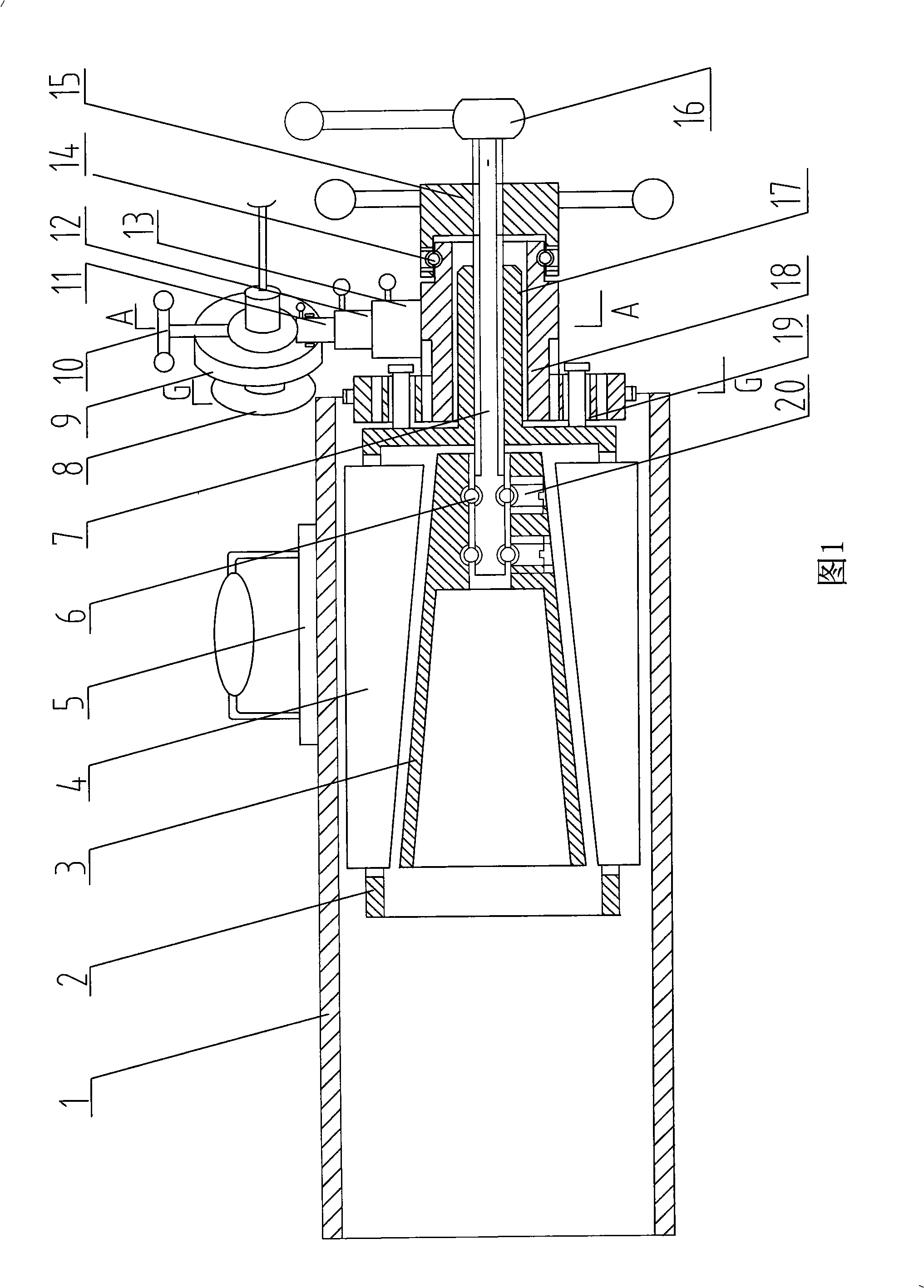

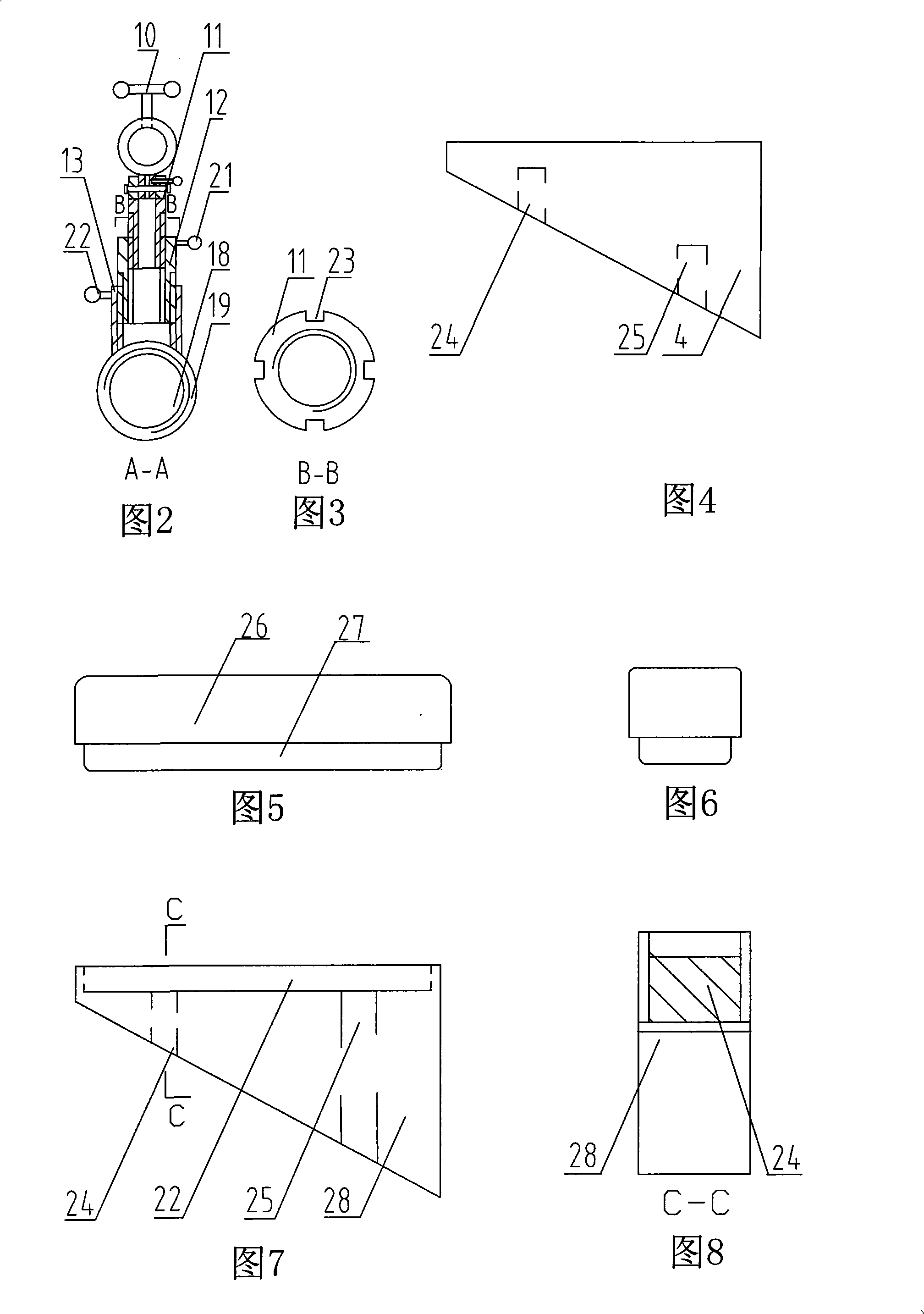

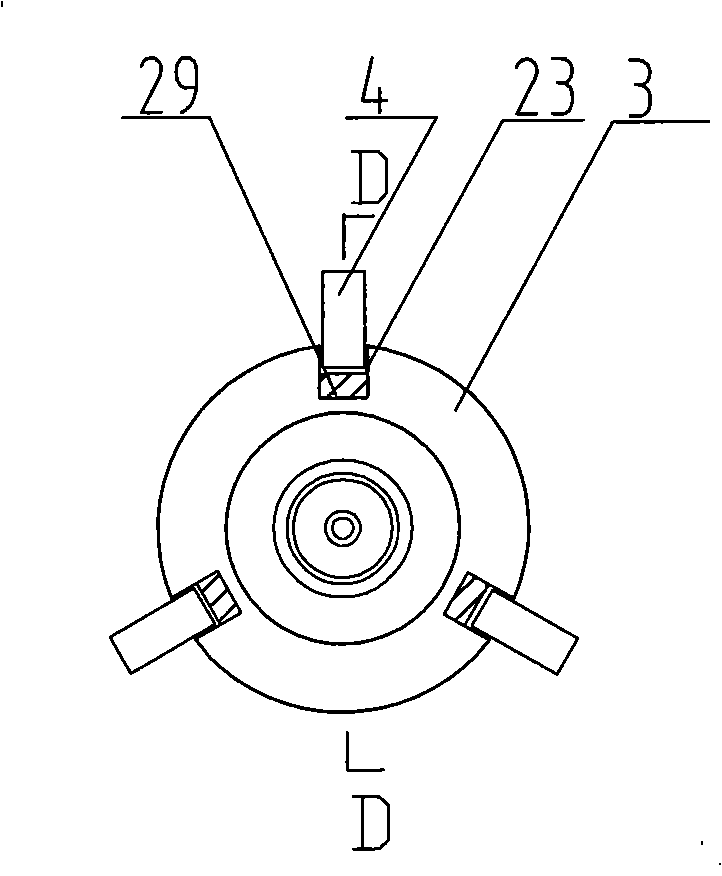

[0033] Referring to the accompanying drawings, the present invention will be further described. In Fig. 1, the pipe beveling machine is mainly composed of a fixing device, a power cutting device and a feeding device. The power cutting device consists of cutter head, electric part, supporting upper rod, adjusting rod, bottom rod and movable sleeve, etc. The feeding device includes axial feeding disc and radial feeding, and radial feeding is as follows: Manually move the operating rod to make the power cutting device rotate radially around the pipe for cutting, or move the ring gear with the handle to make the power cutting device rotate radially around the pipe for cutting.

[0034] When using the beveling machine, first insert the mounting frame 2 of the fixing device into the pipe 1, use the ratchet wrench 16 to move the connecting rod 7 and drive the cone column 3 to move, make the tension block 4 tension the pipe, and use the handle 21 to rotate and adjust Rod 12, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com