Intellectualized rapid quantitative loading process for automobile and loading station

A fast and automotive technology, applied in a method of loading automobiles and in the field of loading stations, can solve the problem of unfixed size and shape of automobiles, and achieve the effect of avoiding random damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

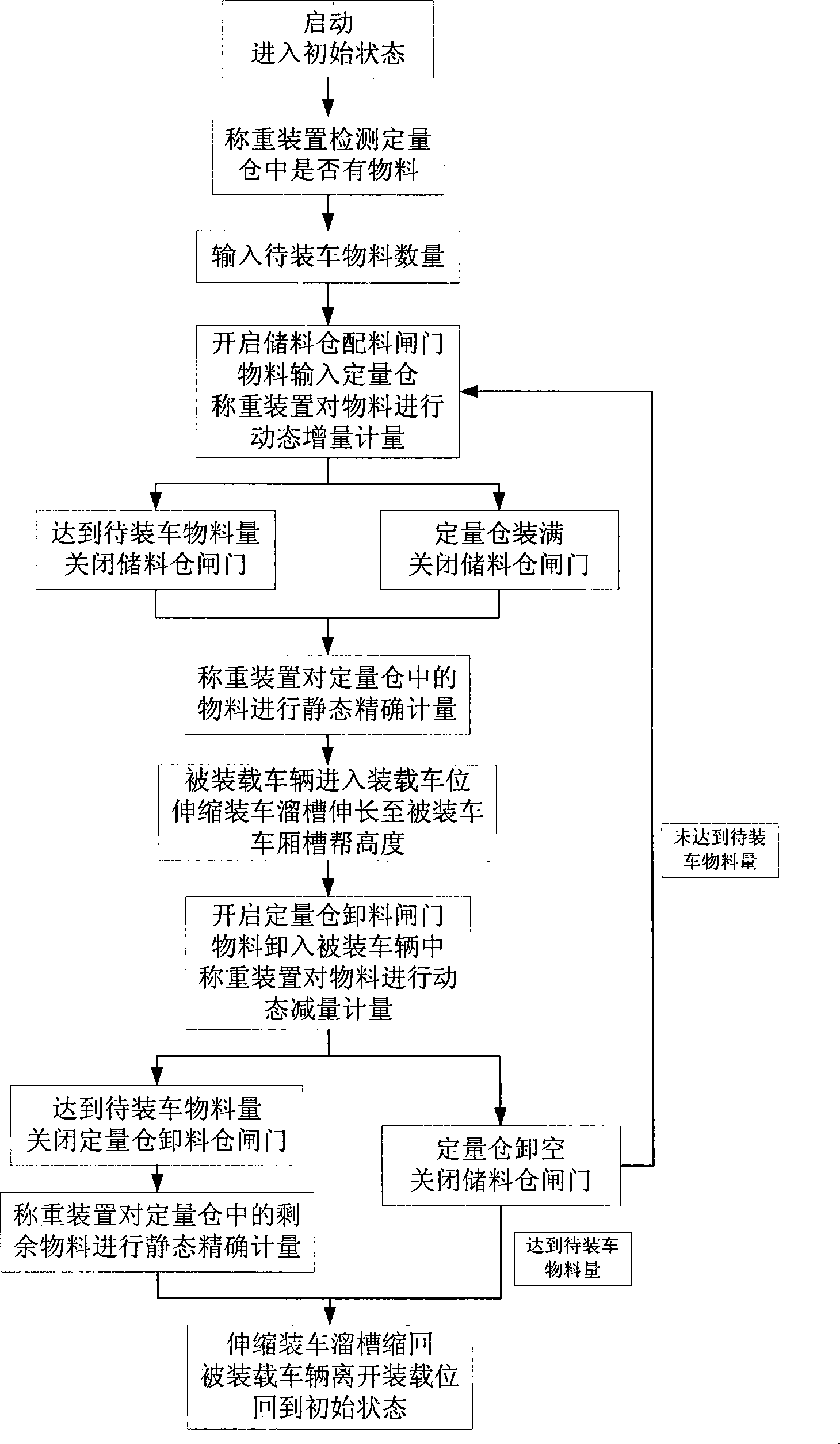

[0032] This embodiment is a specific implementation of the method for fast and quantitative loading of intelligent automobiles. figure 1 It is a schematic diagram of the operation process of the present embodiment. The hardware involved in this embodiment includes: a storage bin, a batching gate for a storage bin, a quantitative bin, a quantitative bin unloading gate, a weighing device, and a telescopic loading chute. figure 2 shown. The whole operation process is as follows:

[0033] Start the loading process and enter the initial state. The initial state is the starting point of the whole process. Before entering the initial state, the system will automatically check whether each part of the equipment is normal, and regularly calibrate the weighing device according to the preset time interval. After everything is normal, it will enter the initial state.

[0034]The weighing device detects whether there is material in the quantitative bin, and measures the quantity if the...

Embodiment 2

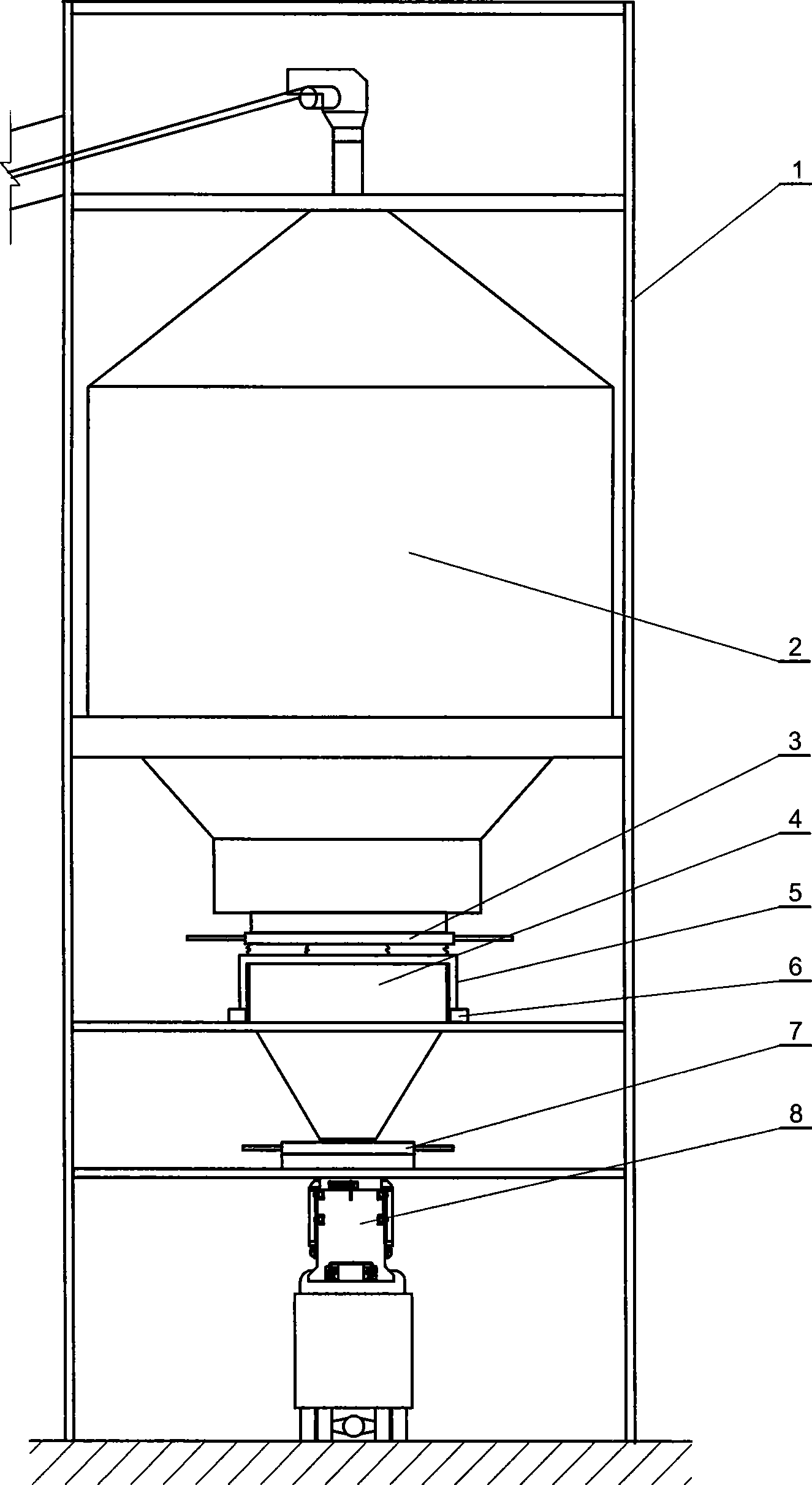

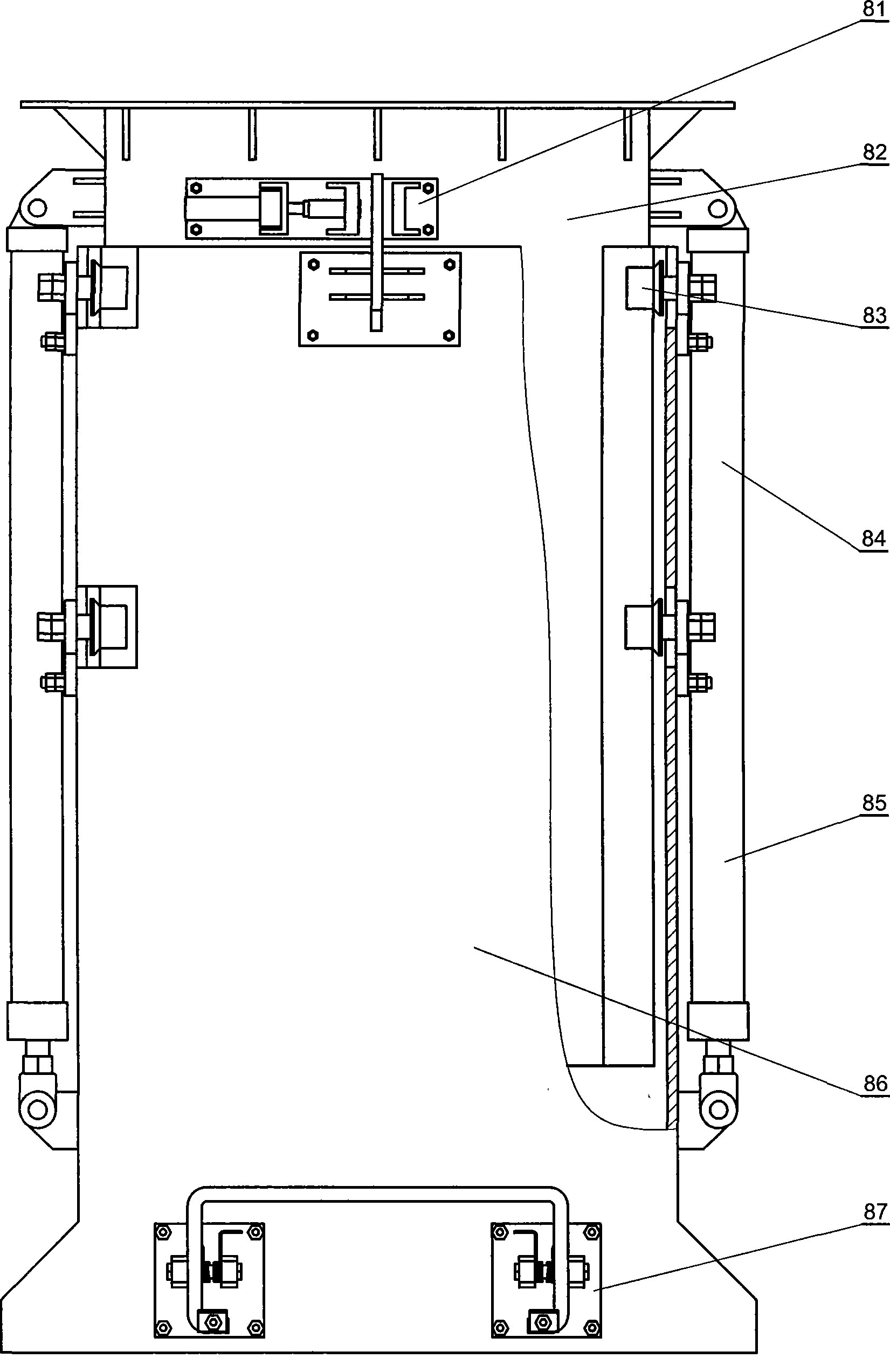

[0060] The present embodiment is to realize the fast quantitative loading station of the intelligent automobile of the method described in the embodiment, the structure is as follows figure 2 shown. This embodiment includes the main support frame 1 as the main body of the loading station. The main support frame is the main body of the fast and quantitative loading station for intelligent automobiles. It can be a steel structure or a reinforced concrete structure. It must have a solid foundation structure or foundation. Similar to a building that needs to be built on site, but the basic structure is made of standard structural parts. What is used in this embodiment is the main support frame of steel structure. On the top of the main support frame, a barrel-shaped storage bin 2 is fixedly installed with an upper inlet for materials and a lower outlet for outlet materials. The storage bin can be a steel structure or a reinforced concrete structure, and the concrete structure us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com