Companding scroll and assembly method thereof

An assembly method and reel technology, which are used in transportation and packaging, door/window protection devices, building components, etc., can solve the problems of high noise, short service life, unstable performance, etc., achieve stable performance, reduce vibration and noise, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

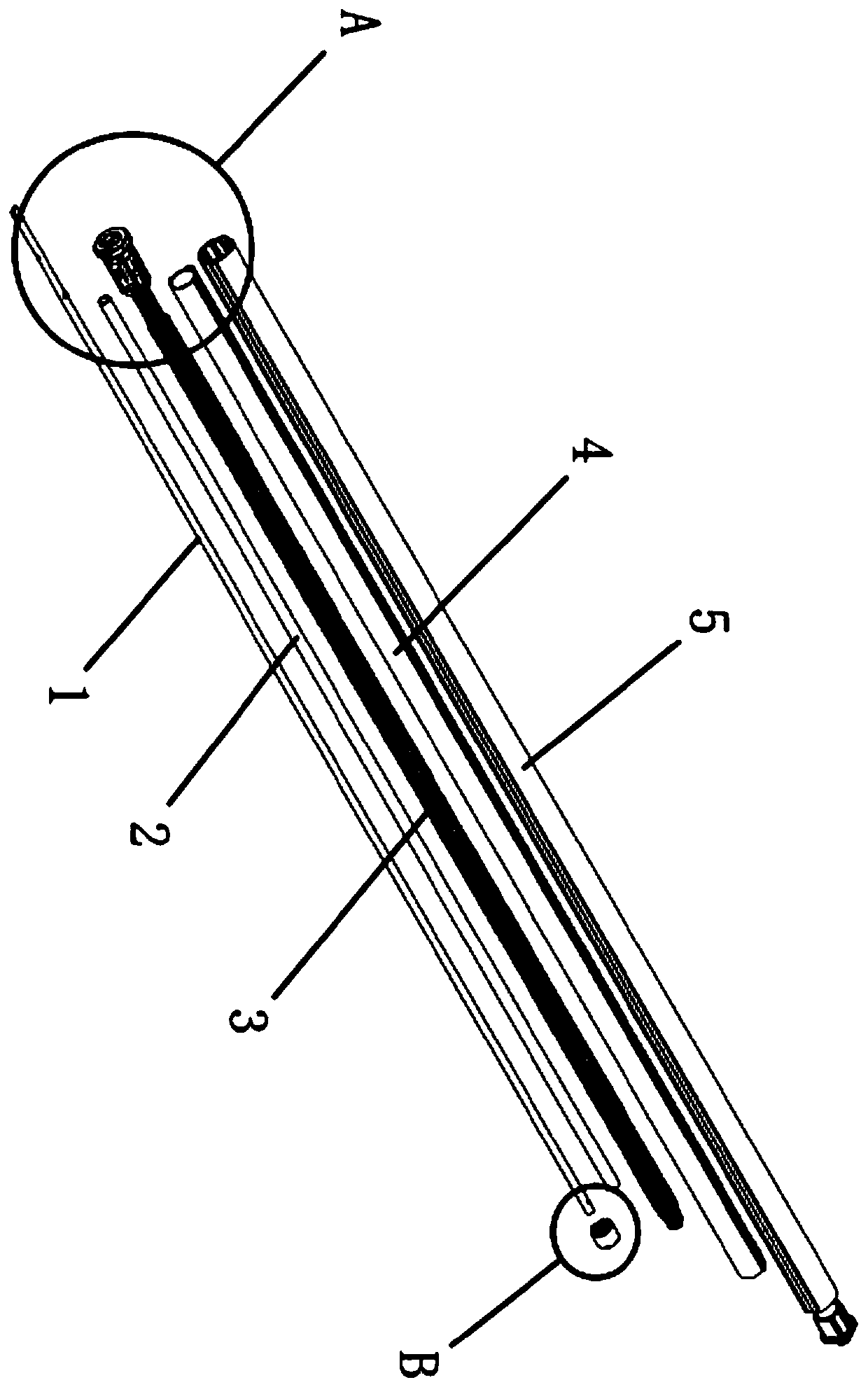

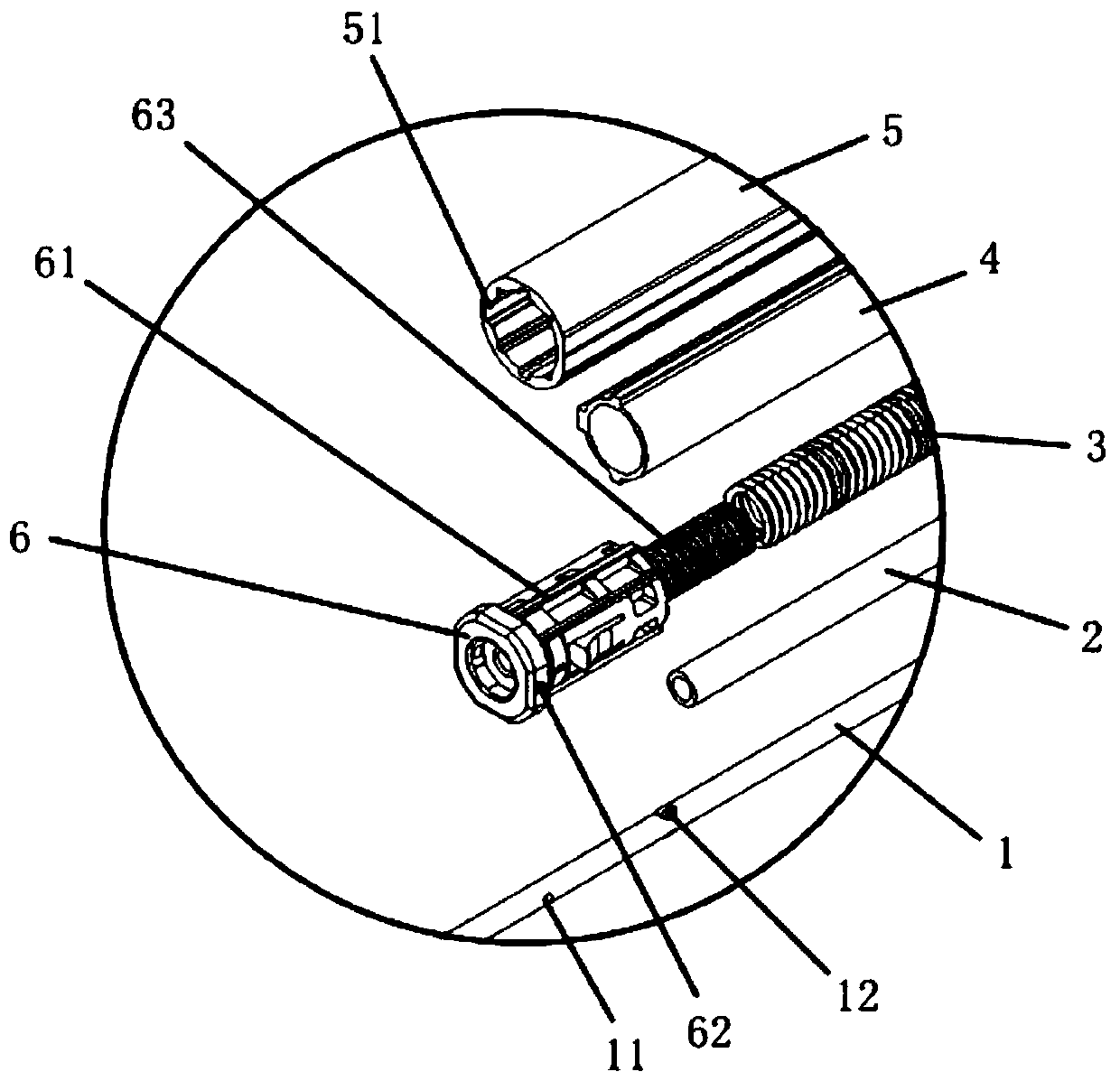

[0028] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0029] In this embodiment, the stretching reel is composed of a mandrel 1, a rubber tube 2, a torsion spring 3, a shock-absorbing and sound-insulating tube 4, and an aluminum tube 5 from the inside to the outside. The rod 1 and the rubber tube 2 are relatively fixed, while the torsion spring 3, the shock-absorbing and sound-insulating tube 4 and the aluminum tube 5 can rotate relative to the mandrel 1. One end of the mandrel 1 is a flat structure, which can be matched with the external car sunroof.

[0030] like Figure 1 to Figure 4 As shown, a compression and stretching reel, the compression and stretching reel includes a mandrel 1, a torsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com