High-temperature resistant water-based insulating liquid

A technology of spacer fluid and high temperature resistance, which is applied in the field of spacer fluid, can solve the problems that the temperature cannot reach the wellbore temperature, the temperature resistance cannot reach 150°C, and the performance index cannot reach the performance index, so as to ensure continuity, stable suspension, The effect of good compatibility

Inactive Publication Date: 2008-11-19

DAQING PETROLEUM ADMINISTRATION

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, SPACE1000 and SPACE3000 are used for water-based mud, while SPACE1001 and SPACE3001 are used for oil-based mud; there are also Dowell's MUDPUSH2 and MUDPUSH WHT two water-based spacers. It does not meet the requirements of wellbore temperature, and other performance indicators do not meet the requirements of the above-mentioned wells, so the price is expensive

There is also Phillips WBS flushing spacer fluid used for deep well high temperature spacer fluid. This spacer fluid has excellent rheology and settlement stability, but the temperature resistance of 150°C cannot meet the above-mentioned wellbore temperature of 150°C.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

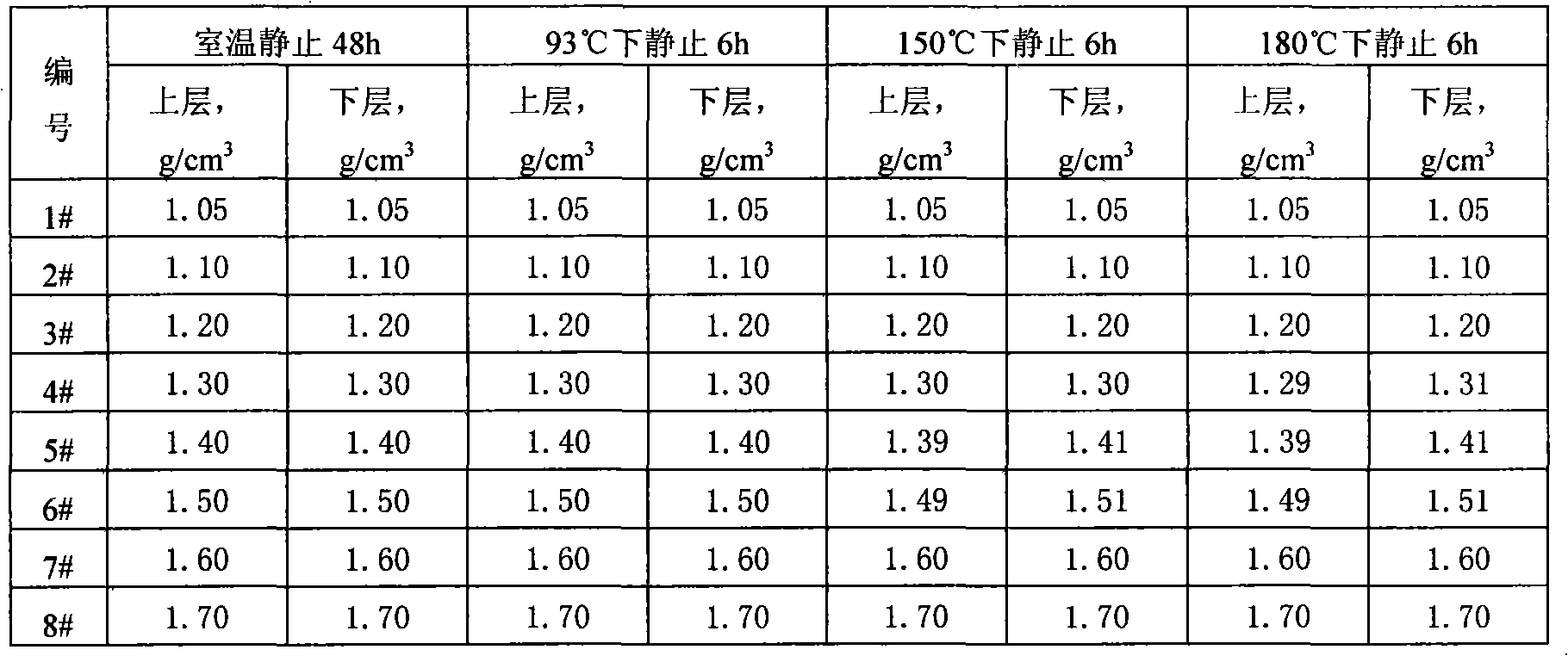

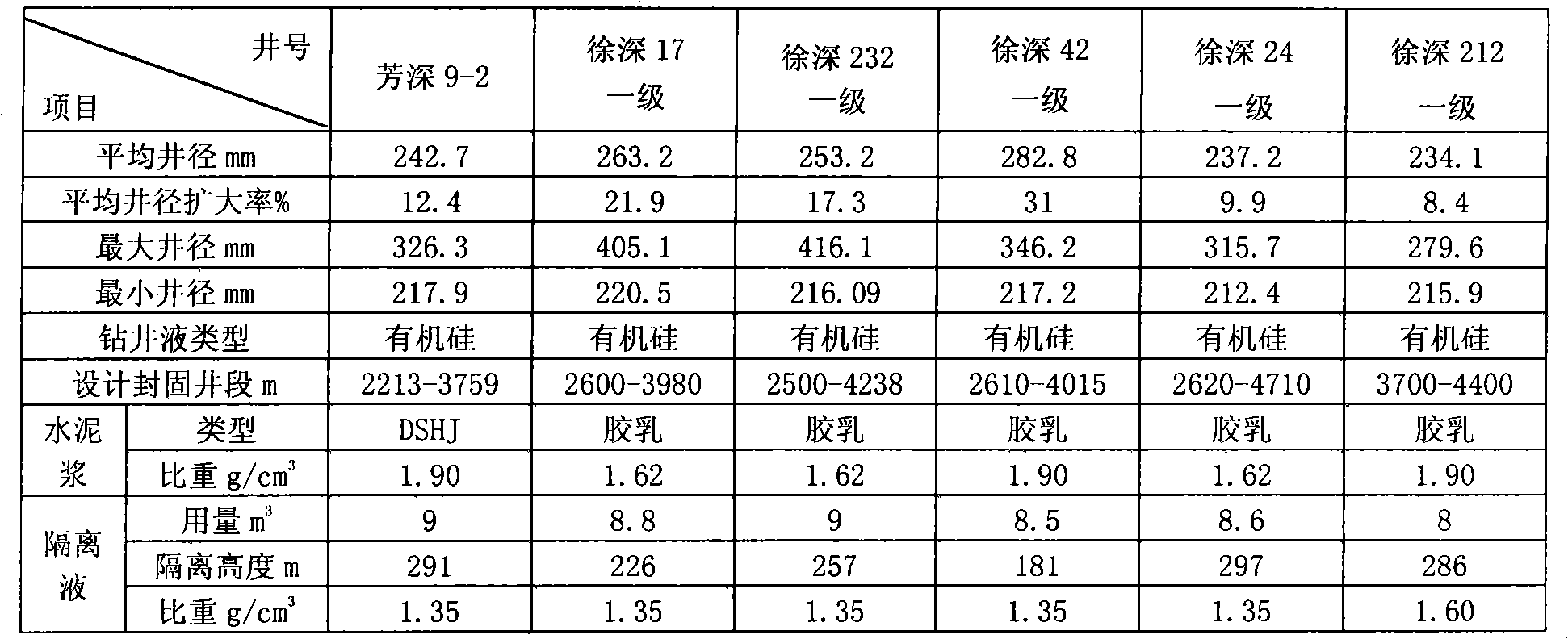

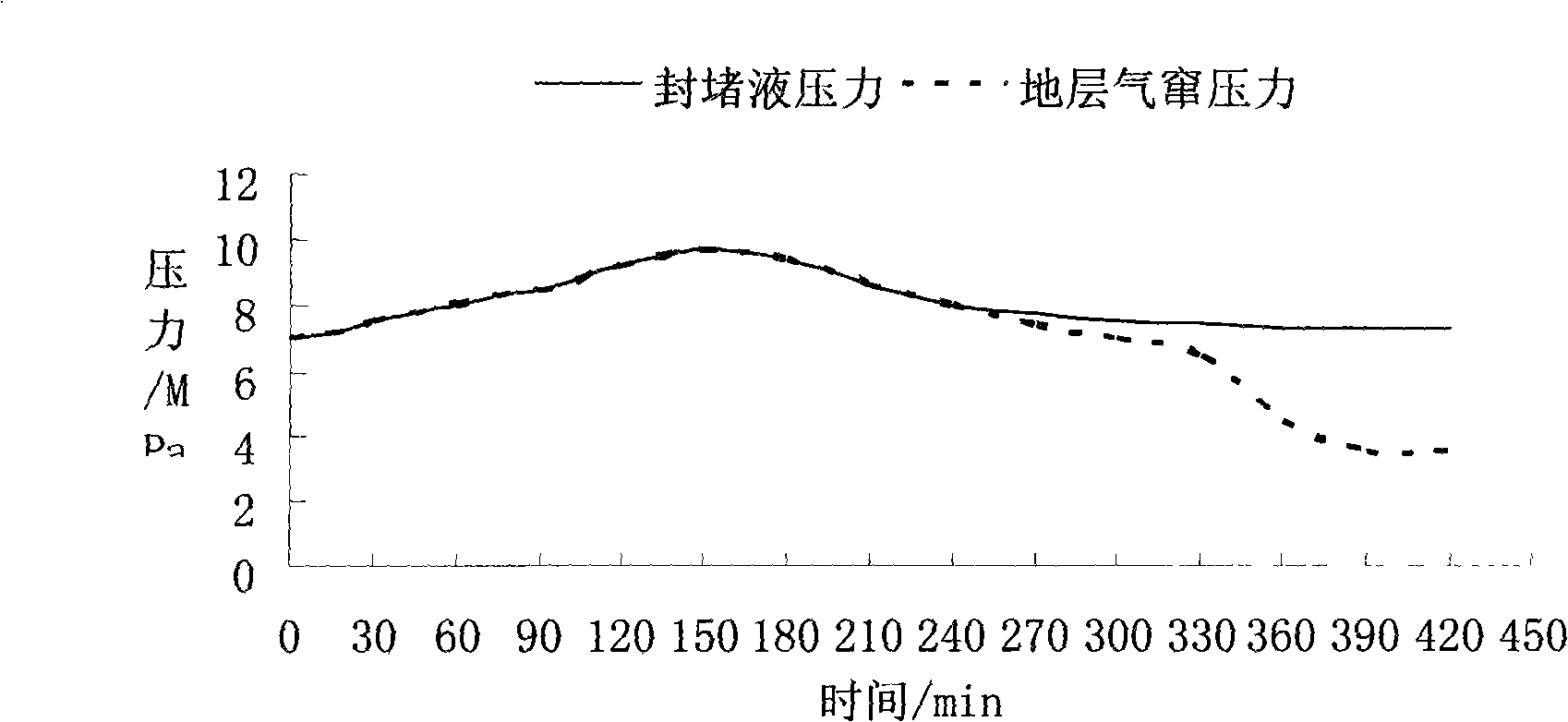

The invention discloses a high temperature resistant sealing liquid which consists of the following compositions by weight portion: 100 portions of water, 5 portions of Attapulgite, 2.5 portions of a suspending agent, 1 portion of polypropylene sulfonate and 0 to 120 portions of baryta powder, wherein, the suspending agent is a multipolymer of vinylphenol, 2 acrylamido-2- methylpropanesulfonic acid, acrylic acid and acrylamide, and the portions of the compositions are weight portions The water-based sealing liquid has the functions of pressing, stabilizing, separating and replacing, etc. in the well cementation process of a deep well and an ultradeep well (a well bottom circulating temperature is up to 180 DEG C); moreover, the water-based sealing liquid can improve the interface cementation quality.

Description

Technical field: The invention relates to a spacer fluid used in the field of drilling and cementing in oil fields, in particular to a high-temperature-resistant water-based spacer fluid. Background technique: With the increasing demand for oil and gas, the increasing difficulty of oil and gas exploration, the emergence of deep wells, ultra-deep wells and complex oil and gas wells, the requirements for the cementing quality of oil and gas wells and the difficulty of improving the cementing quality are getting higher and higher, and more and more High wellbore temperature also poses a problem for cementing technology. The original spacer fluid technology in China can no longer meet the needs of modern cementing. Domestic complex oil and gas reservoir exploration and development and cementing quality problems of special wells are mainly reflected in low cementing displacement efficiency, annular oil and gas water channeling and poor interface cementation quality problems, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K8/40

Inventor 王广雷杨智光和传健徐明弓玉杰姜涛姜晓超

Owner DAQING PETROLEUM ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com