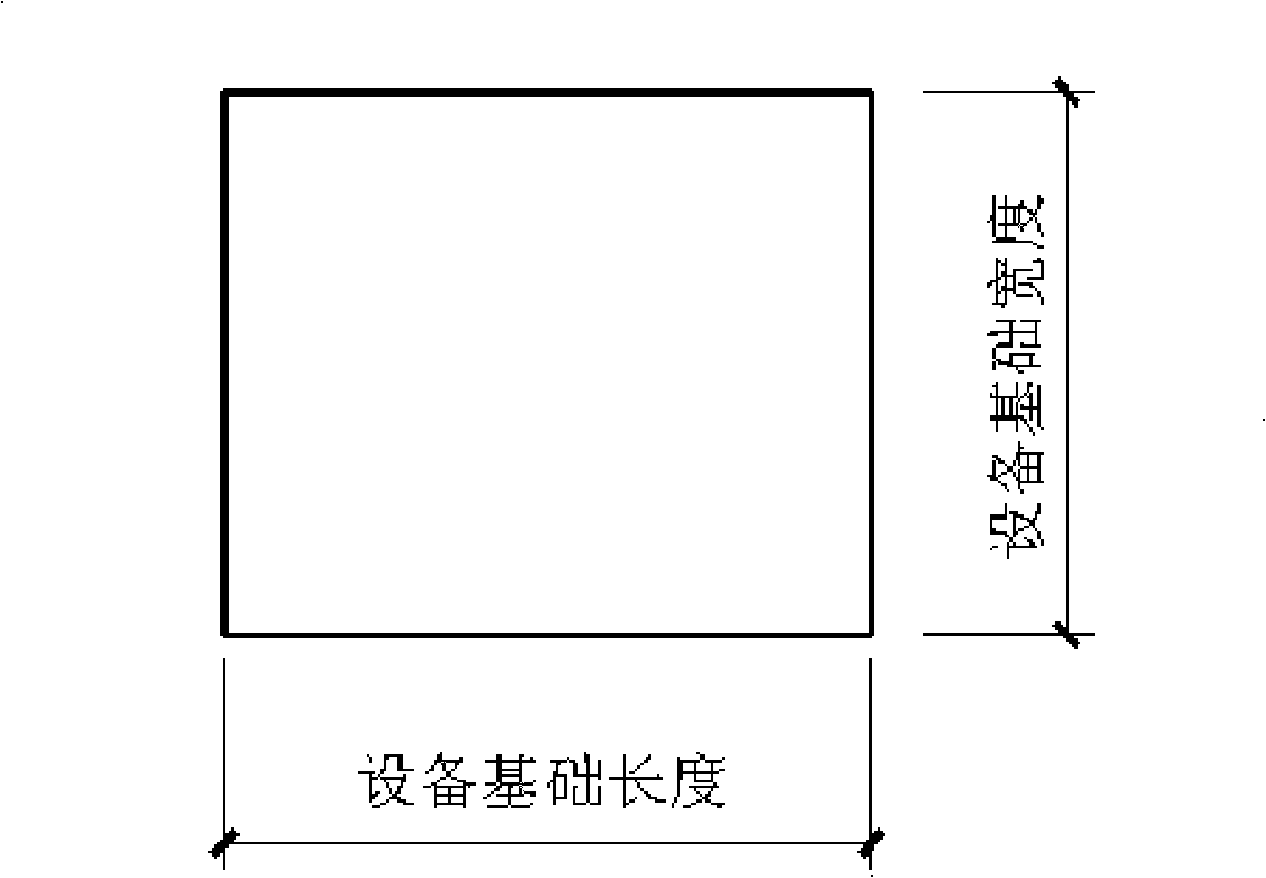

Elevated large-sized apparatus foundation structure

A large-scale equipment and basic technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of reduced engineering safety, easy cracks in concrete, waste of materials, etc., to reduce the occurrence rate, avoid concrete cracks, and reduce the heat of hydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

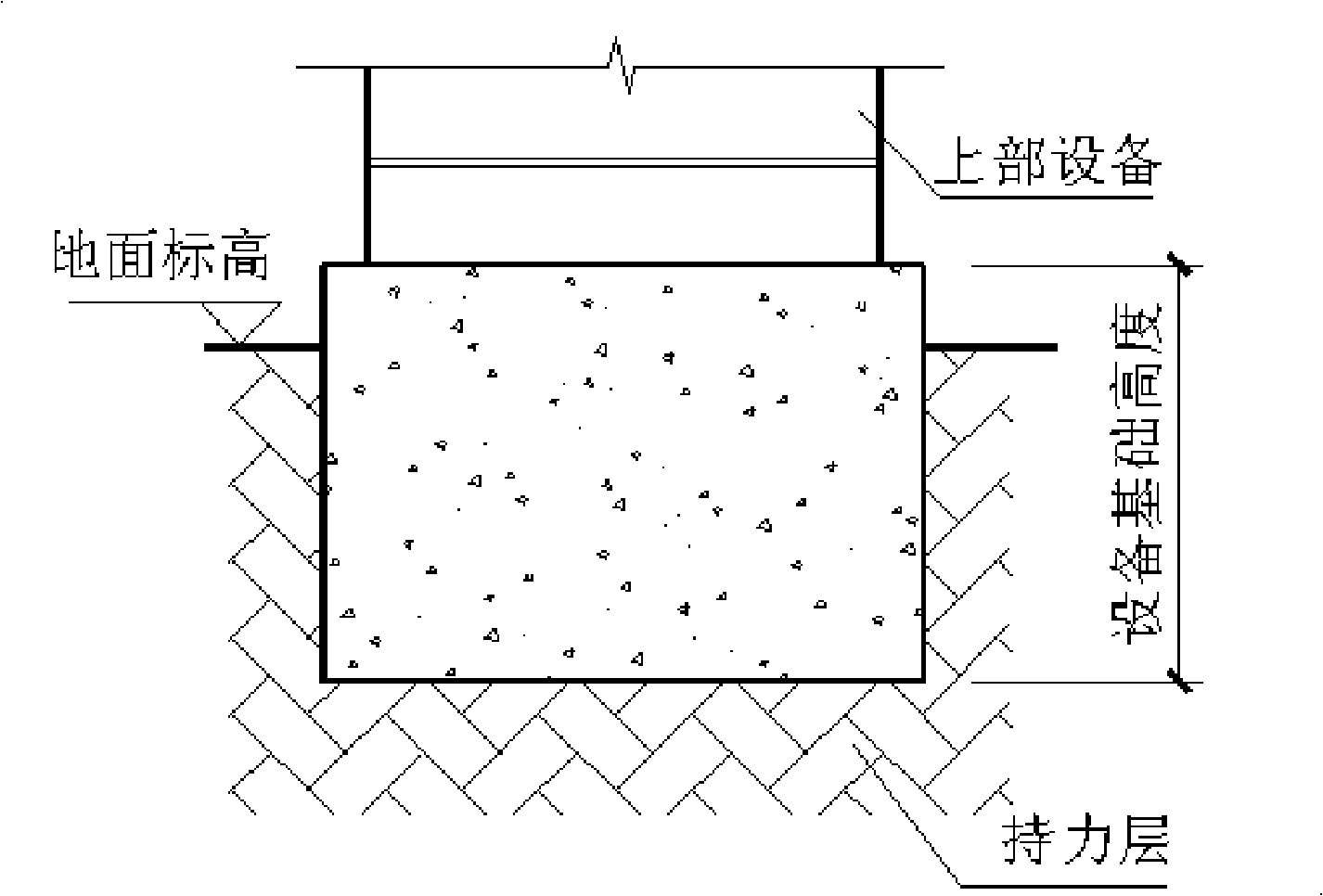

[0013] Embodiments of the present invention: In the following, we take a rectangular equipment foundation with overhead design as an example to illustrate the construction steps of the present invention. Of course, the invention is not limited to rectangular equipment foundations, and circular or even special-shaped equipment foundations can be used. structure.

[0014] First, calculate the weight of the upper equipment and its supporting position on the equipment foundation;

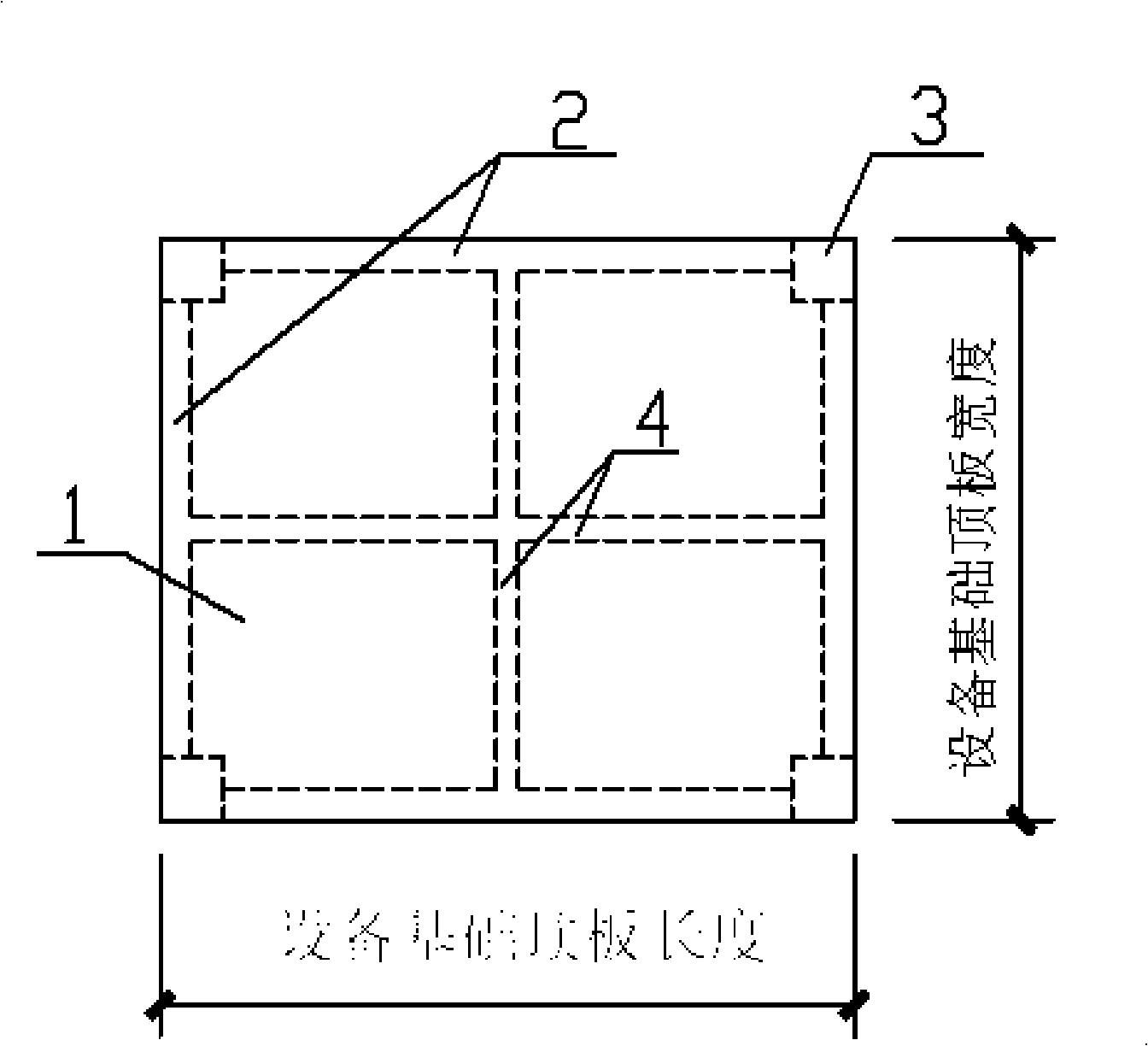

[0015] Second, rationally arrange the positions of the underground frame column 3 and the column reinforced concrete foundation base 7, and arrange the frame beam 2, the middle beam 4, and the reinforced concrete slab 1 on the underground frame column 3 according to the position of the equipment on the foundation;

[0016] Third, design and calculate the beam, slab, and column system formed above according to the reinforced concrete frame structure;

[0017] During construction, the fixed-point foundation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com