Sharply inclined coal seam mining method

A mining method and a technology of steep inclination, which are applied in the field of roof control by flexible cover supports in steeply inclined coal seams, can solve the problems of restricting single-level excavation, roadway support, difficult maintenance, and heavy outburst prevention workload, etc., and achieve reduction The effect of digging the number of cut holes, reducing the workload of preventing outbursts, and reducing the loss of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

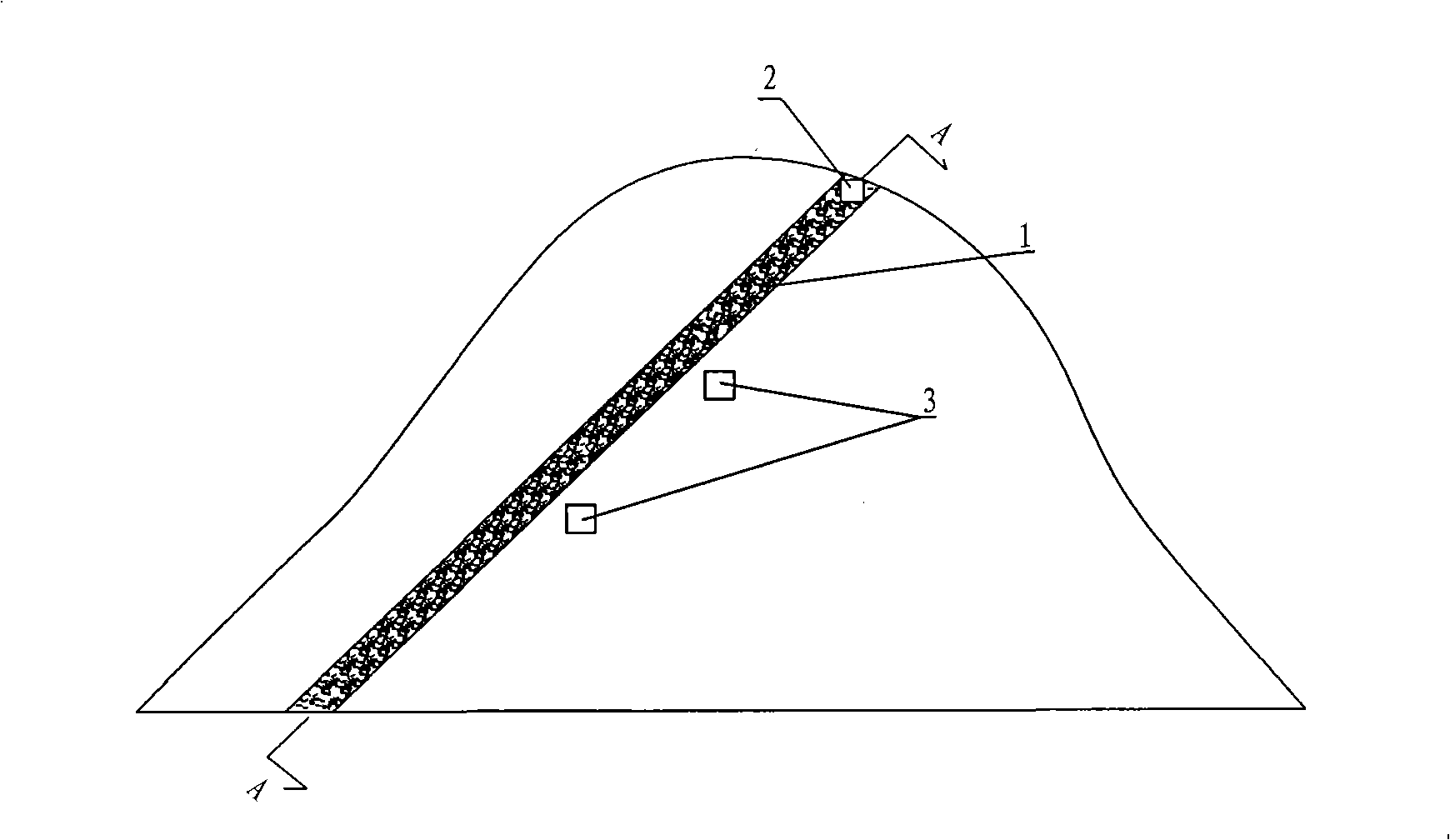

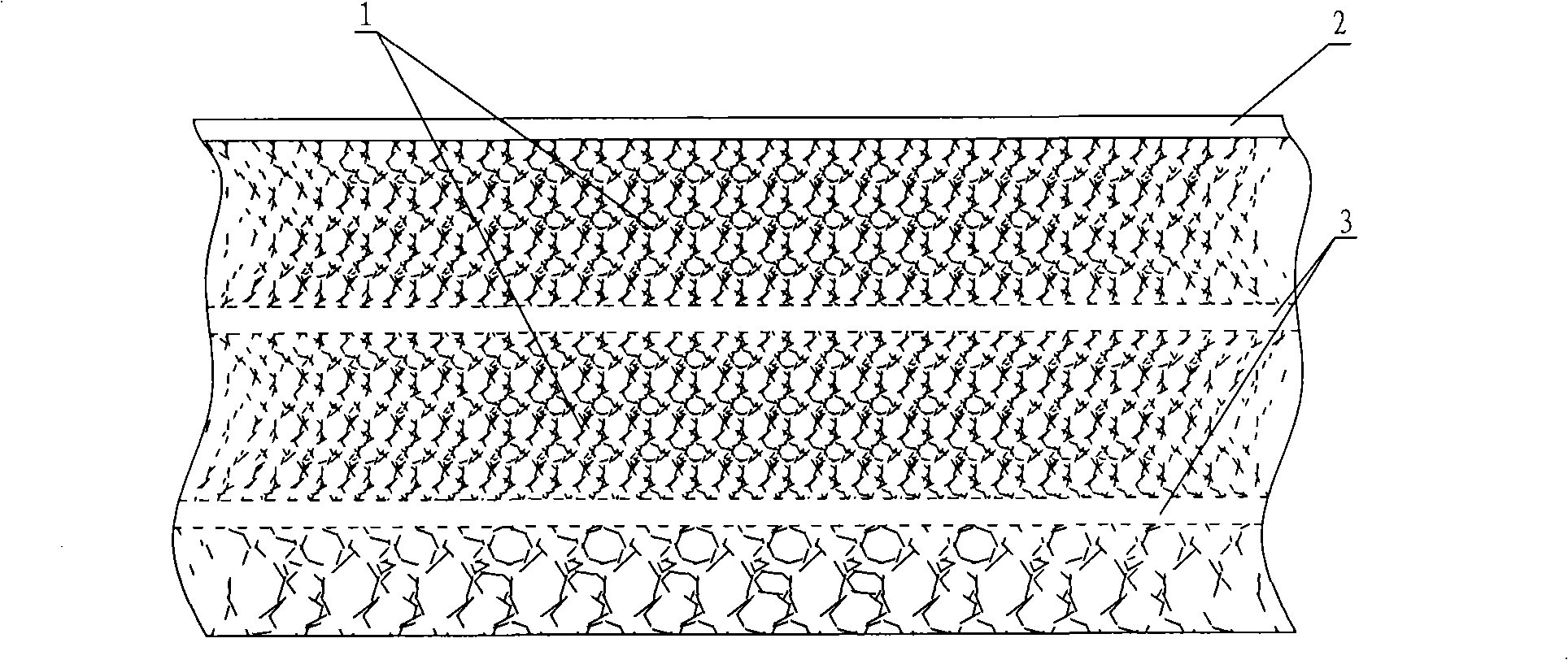

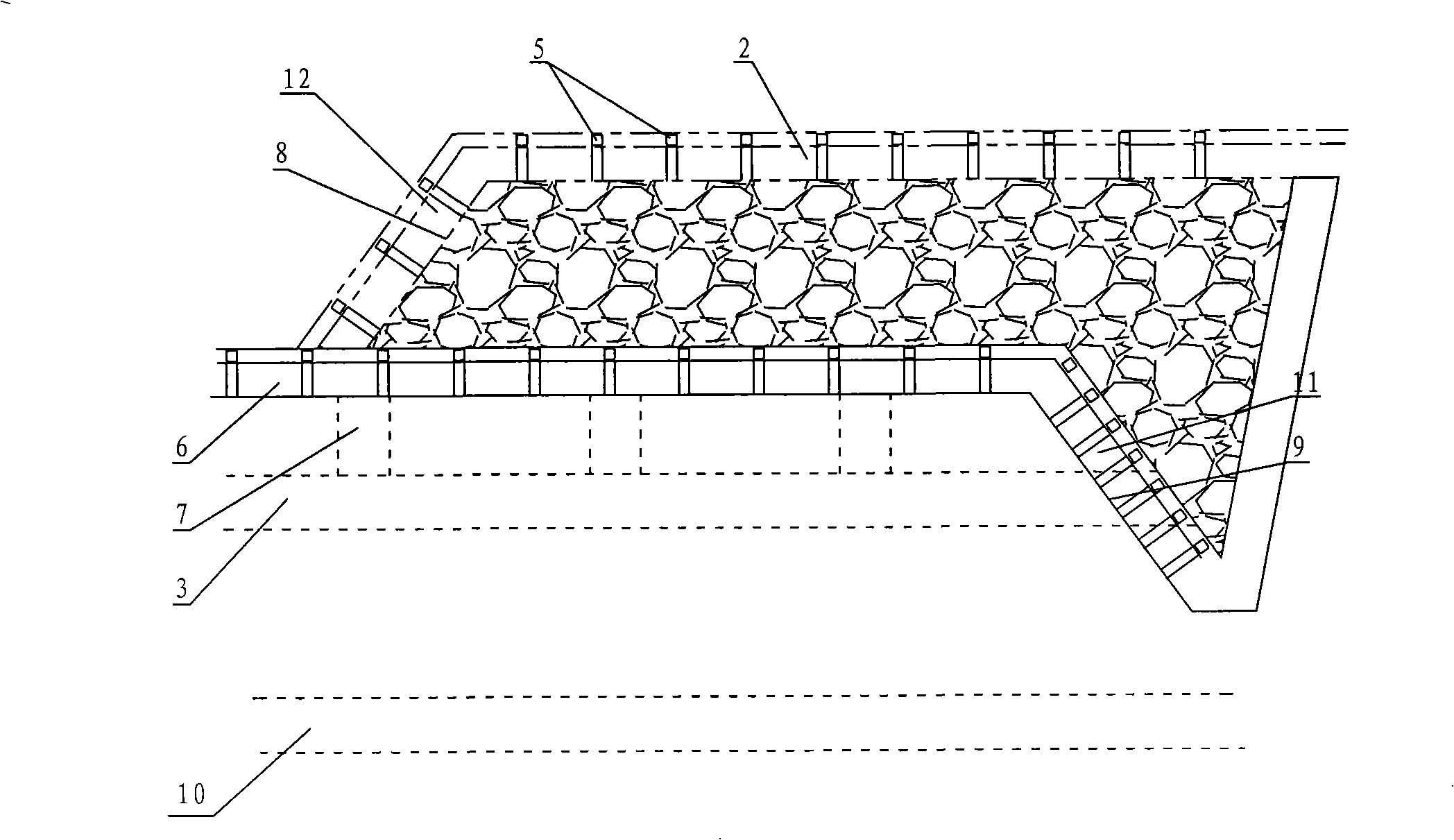

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the mining method of the steeply inclined coal seam consists of the following steps:

[0030] Step 1, open the air return roadway 2 in the steeply inclined coal seam 1 by blasting and driving, and open the transport machine roadway 3 at the rock formation 4 of the steeply inclined coal seam 1 below the return air roadway 2, and the distance between the transport machine roadway 3 and the steeply inclined coal seam 1 is 3 ~ 4m.

[0031] Step 2, first excavate a pseudo-inclined first cutout 12 in the steeply inclined coal seam 1 above the conveyor lane 3, the upper end of the first cutout 12 communicates with the return airway 2, and the first cutout 12 The lower end communicates with the conveyor lane 3 through the connecting inclined lane 7, and the distance between the adjacent connecting inclined lanes 7 is 80-100m. Then place the flexible cover support 5 control top in the first cut hole 12 to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com