Three-dimensional micro- force silicon micro- sensor

A silicon microsensor and three-dimensional microforce technology, which is applied in the field of three-dimensional semiconductor piezoresistive microforce silicon microsensors, can solve problems such as the lack of ability to measure micro-forces acting on the micro-new level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

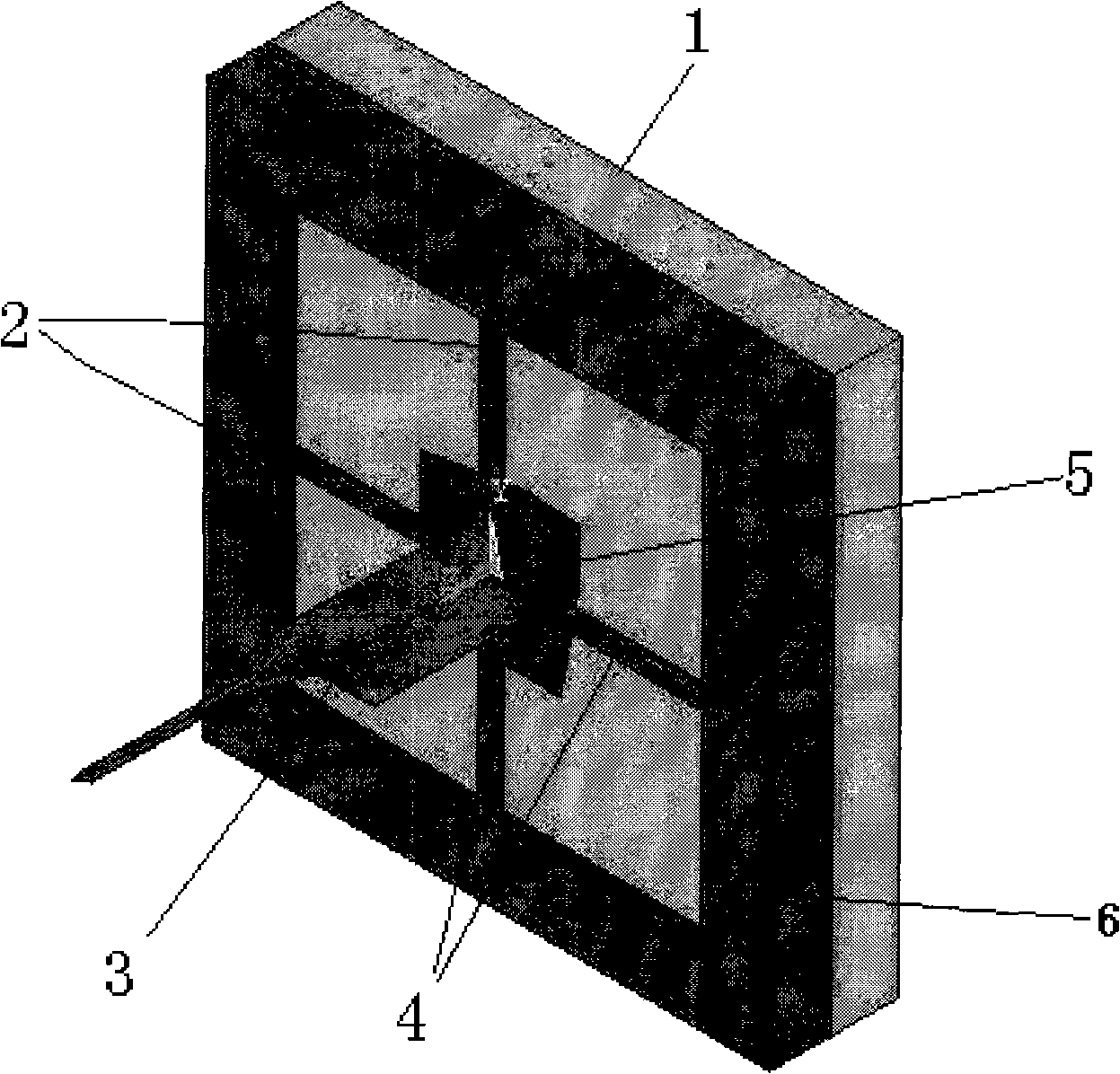

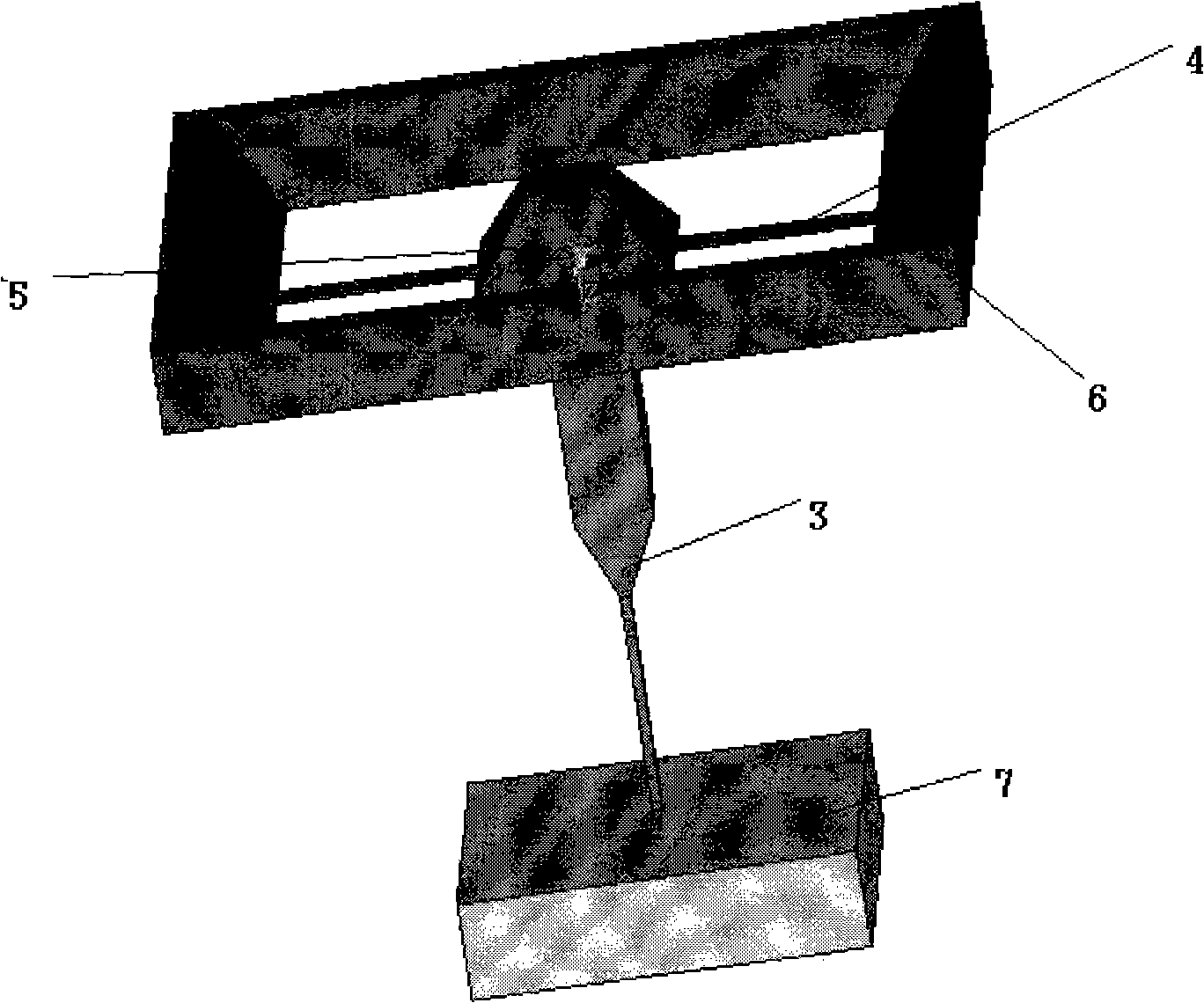

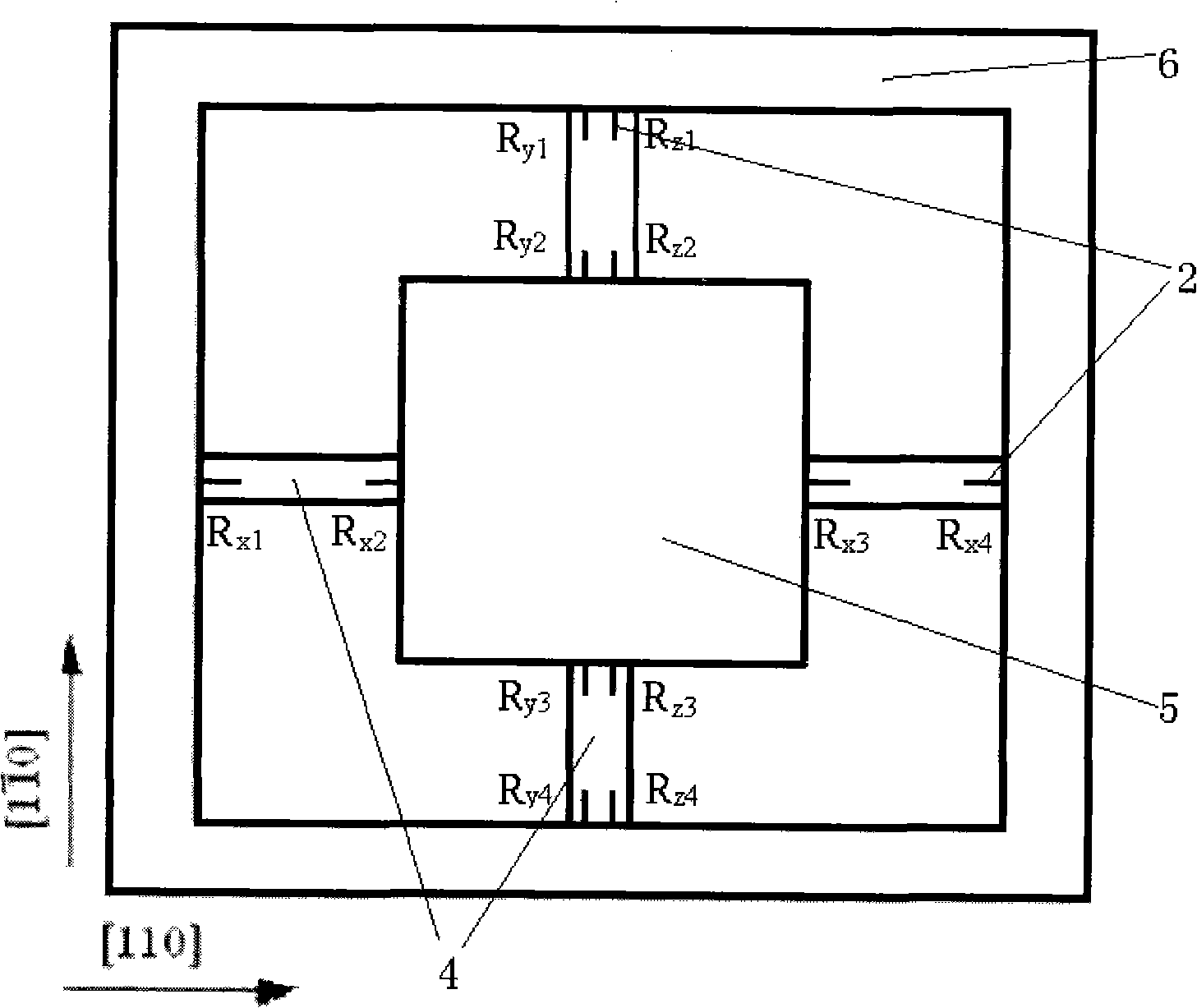

[0017] see figure 1 , the invention mainly includes two parts: a micro-mechanical probe and a three-dimensional force conversion platform with a four-cantilever beam structure. Its specific structure is: a three-dimensional micro-force silicon microsensor, including a glass substrate 1, a silicon side wall 6 is arranged on the glass substrate 1, and four single-end fixed-supported silicon cantilever beams 4 perpendicular to each other are arranged in the middle of the silicon side wall 6. The cantilever beam 4 supports the mass suspension block 5 in the middle, and the micromechanical probe 3 is arranged on the mass suspension block 5, and a set of piezoresistive strips 2 is arranged on each of the four cantilever beams 4, and four sets of piezoresistive strips 2 are arranged as Wheatstone bridge. The thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com