Concentrated winding machine with magnetic slot wedges

A magnetic slot wedge and winding technology, which is applied in windings, manufacturing motor generators, electromechanical devices, etc., can solve the problems of reducing the strength and rigidity of the stator mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following detailed description is merely exemplary in nature and does not limit the use of the invention. Furthermore, the invention is not limited by any expressed or implied theory presented in the preceding technical field, background, brief summary, or the following detailed description.

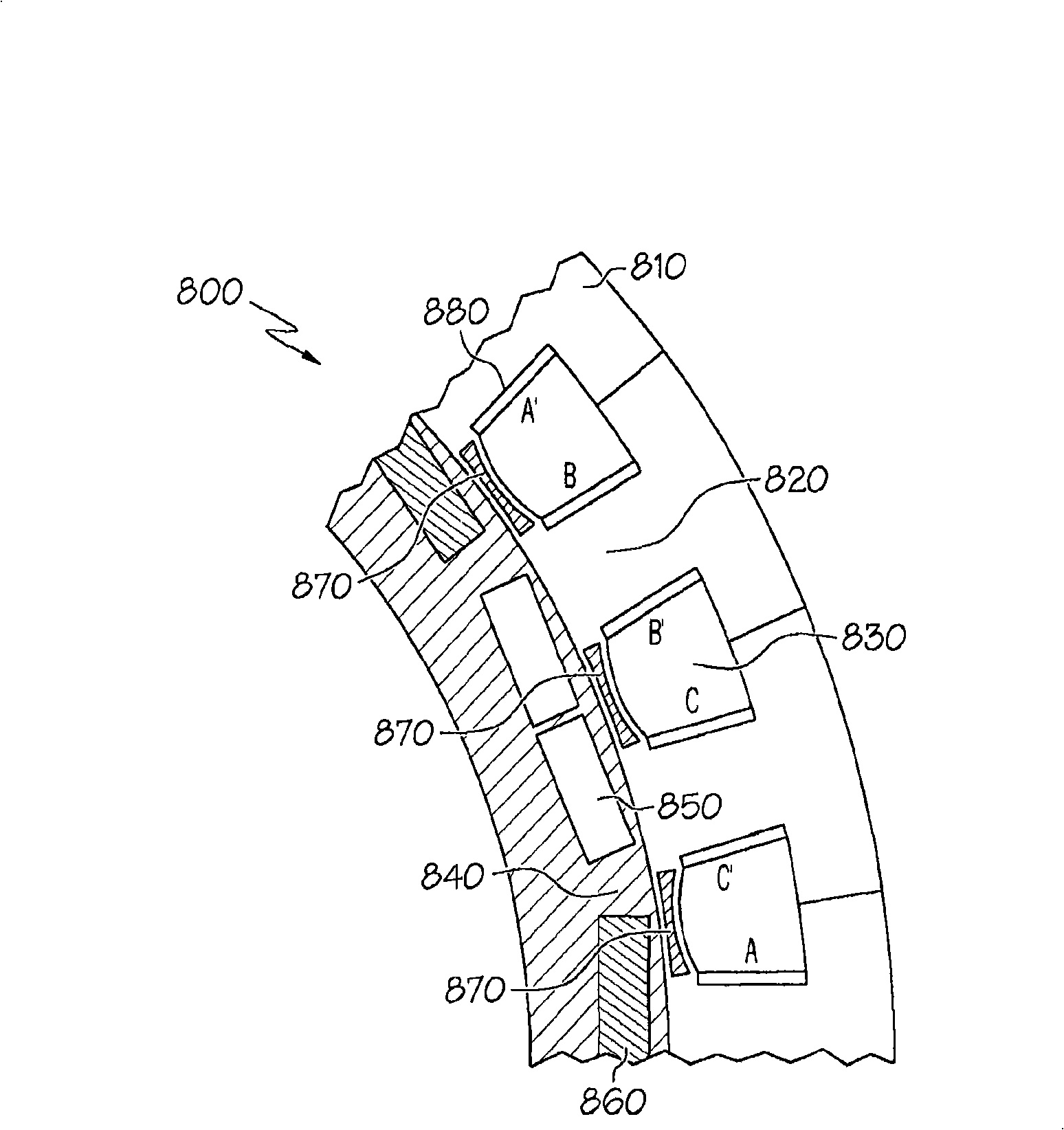

[0028] Figure 4 is a cross-sectional view of stator slot and rotor pole placement in concentrated winding machine portion 800 according to one embodiment. shown in Figure 4 The portion 800 of has a period of 8, ie only 1 / 8 of the entire geometry is shown in the figure.

[0029] In portion 800 , each fixed tooth stator segment 810 has stator teeth 820 with stator slots 830 formed between adjacent stator teeth 820 . Also shown in portion 800 is rotor 840 , rotor north pole 850 and rotor south pole 860 . In total there are 24 stator slots 830 and 16 rotor poles 850, 860, ie a slot to pole ratio of 1.5. For convenience, the Figure 4 The geometry of is called 24-16 geometry. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap