Complex type filter board of plate frame filter press

A plate-and-frame filter press and filter plate technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of unreasonable filter plate structure, low overall rigidity and strength, etc., and achieve the elimination of mechanical heating and Ambient temperature effect, improved service life, novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

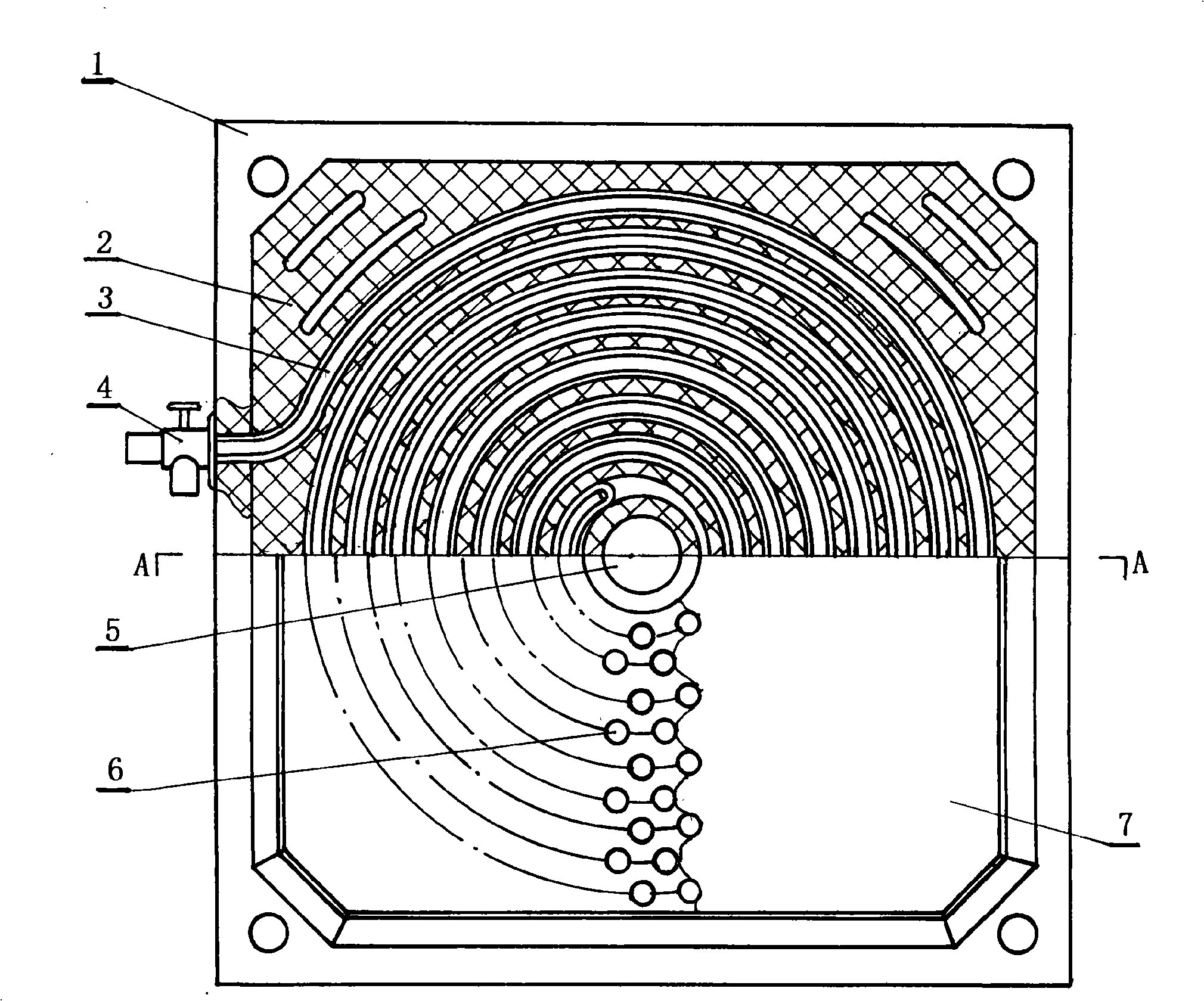

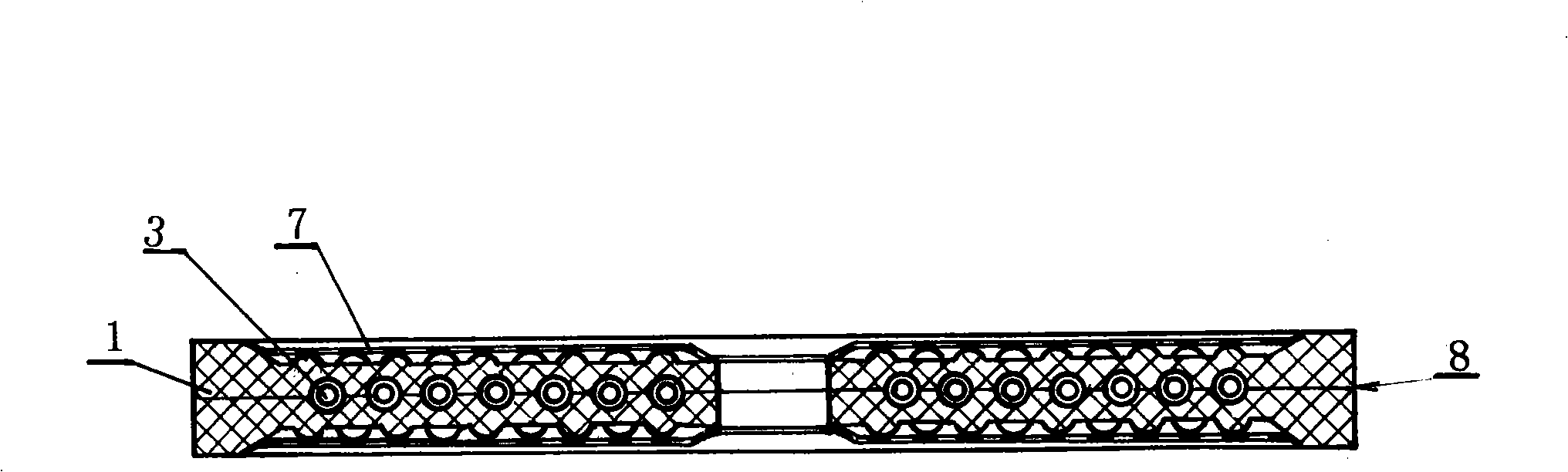

[0017] as attached figure 1 , figure 2 In the shown embodiment, the present invention is a box-type filter plate formed by bonding two half-type filter plates with an adhesive layer 8. A filter plate is embedded in the body with a center feeding hole 5 as the axis of the filter plate. The flat-disc scroll spiral sleeve 3, the inner end of the sleeve 3 is closed, and the outer end pipe joint is fixedly connected to the frame of the filter plate and connected to the double valve 4 disclosed in Chinese Patent No. 200620023302.1. Several filter cloth supports 6 are formed on the outer filter surface of the plate body and the cover is connected with the filter cloth layer 7 .

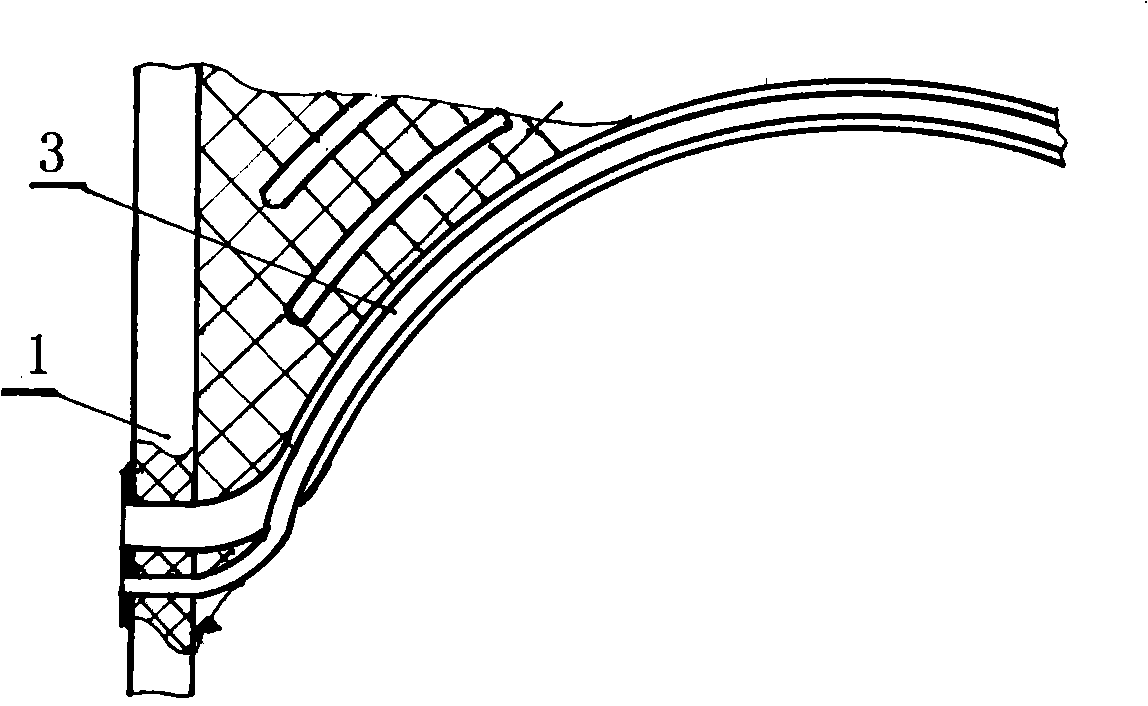

[0018] See attached image 3 In an embodiment, the pipe joint of the casing 3 of the present invention is fixedly connected to the pull frame of the filter plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com