Triaxiale self-synchronizing elliptical vibrating screen

An elliptical vibration, self-synchronizing technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of increasing the manufacturing cost and difficulty of the vibrating screen, unfavorable development of the large-scale vibrating screen, complex structure of the vibrating screen, etc., and achieves a simple structure. , Easy installation, manufacture and maintenance, the effect of increasing the length

Active Publication Date: 2008-11-26

鞍山鞍重矿山机械有限公司

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the complex structure of the vibrating screen and high installation precision requirements, the manufacturing cost and difficulty of the vibrating screen are greatly increased.

Since the existing vibrating screen is forced to operate synchronously, the distance between the vibrating axes is limited to a certain extent, so this structure is not conducive to the large-scale development of the vibrating screen

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

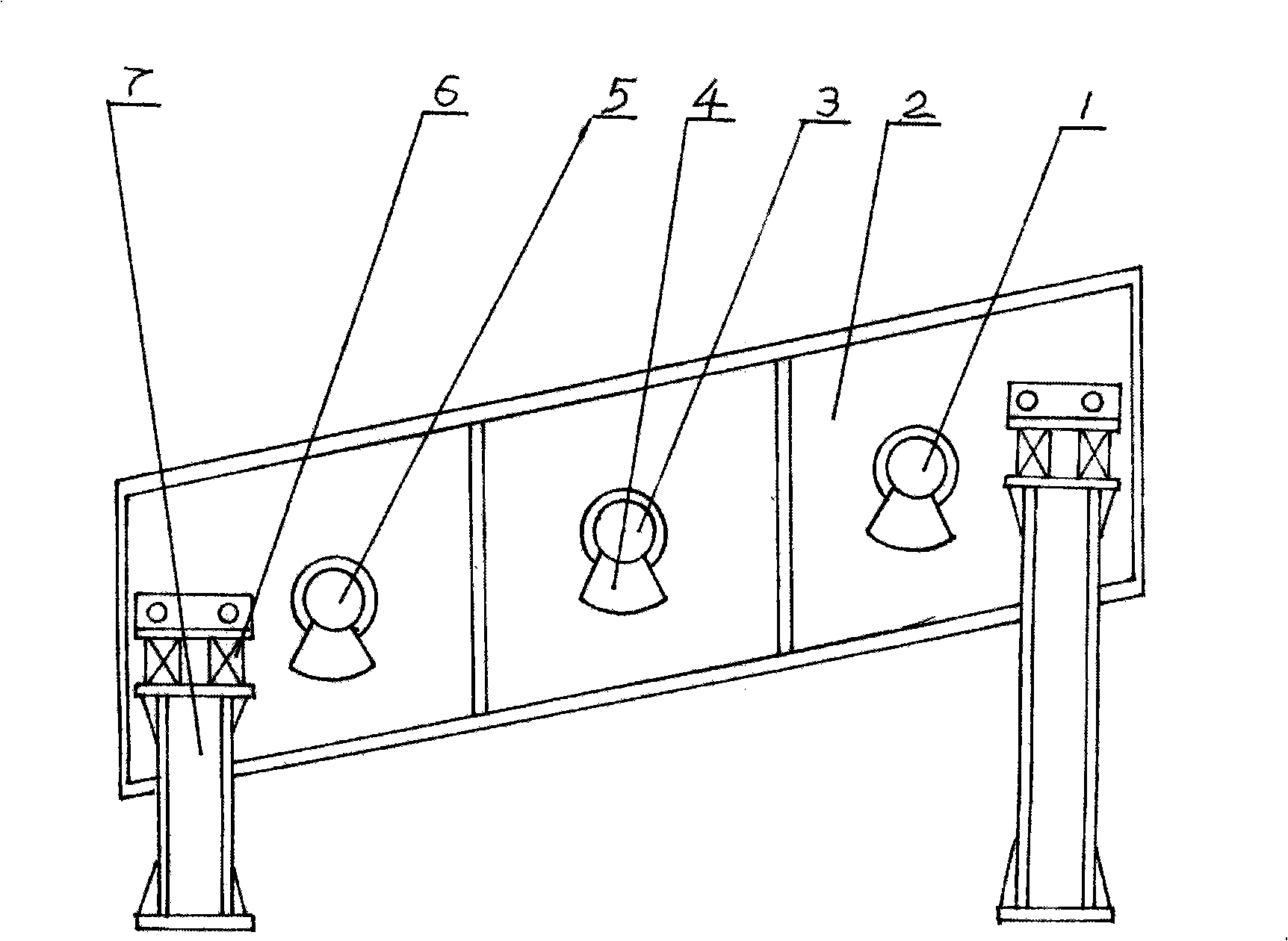

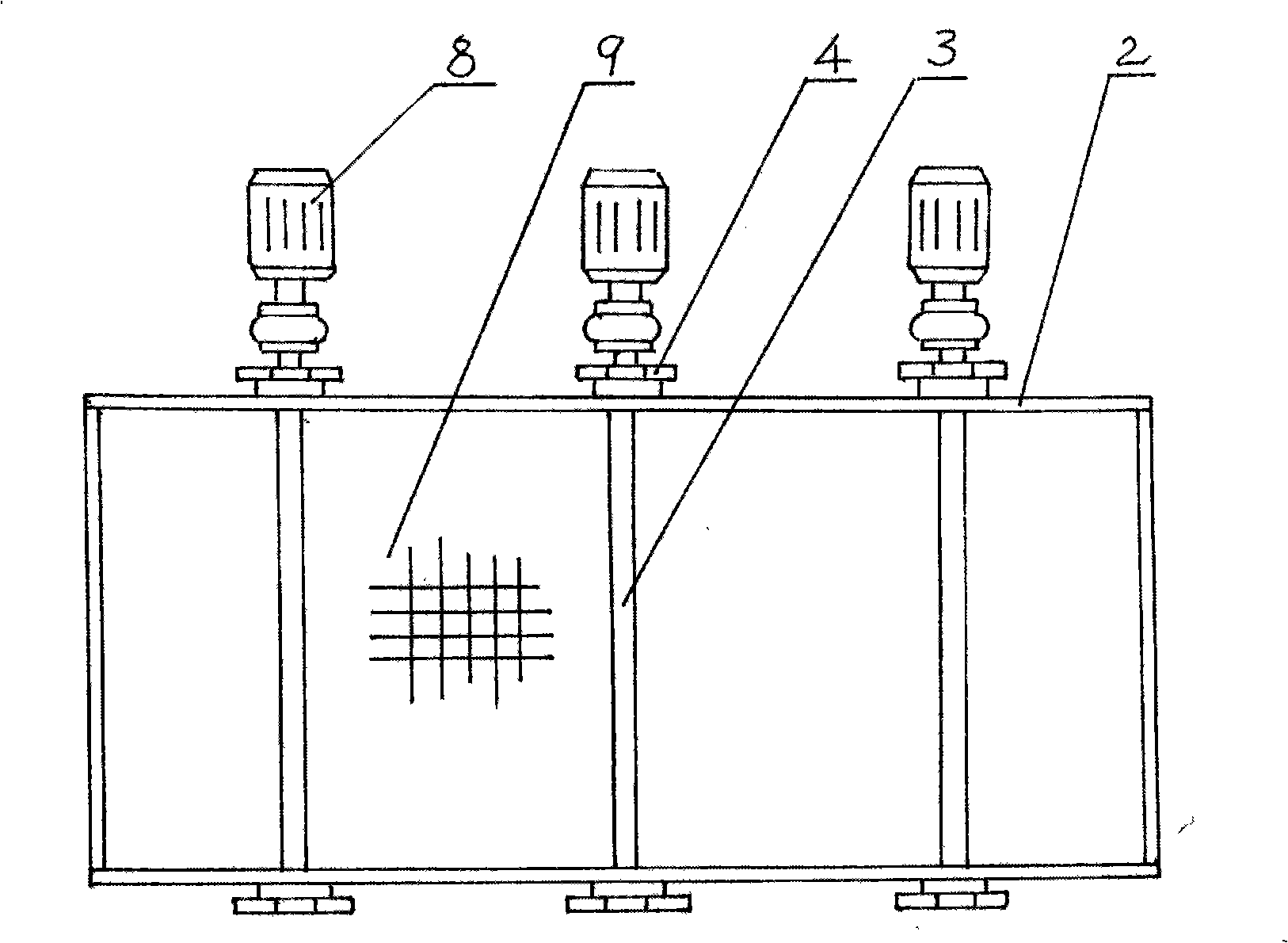

The invention discloses a three-axis self-synchronization ellipse vibrating screen, pertains to the vibrating screening machine field, and is designed to aim at the problems of complex structure, high installation precision and influence on the large-scale development of the existing ellipse vibrating screen. The vibrating screen is provided with three separate vibrating axes from the feed inlet end to the feed outlet end; both ends of each vibrating axis are both provided with an eccentric block driven by three motors; two vibrating axes at both ends of a screening box rotate in opposite directions so that the vibrating screen can rotate by self-synchronization along an ellipse moving track with the major axis of the ellipse vertical to the screen face. Therefore, the distance between the vibrating axes can be lengthened and the large scale of the vibrating screen can be realized. In addition, the three-axis self-synchronization ellipse vibrating screen of the invention is characterized by simple structure and convenient installation, manufacturing and maintenance and can be applied to the materials screening for the sectors of metallurgy, mines, transportation, hydroelectricity, etc.

Description

Three-axis self-synchronizing elliptical vibrating screen technical field The invention belongs to the field of vibrating screening machinery, and mainly relates to a three-axis self-synchronizing elliptical vibrating screen capable of classifying difficult-to-screen materials. Background technique The currently used elliptical vibrating screen generally has three vibration axes, which are installed on the two side plates of the screen box. At both ends of each shaft, eccentric blocks with equal eccentric weight and same eccentric radius are installed on the side plate of the screen box. Through the gear connection of equal parameters, it is forced to run synchronously. It is an elliptical motion track vibrating screen composed of linear motion track and circular motion track. Due to the complex structure of the vibrating screen and high requirements for installation accuracy, the manufacturing cost and difficulty of the vibrating screen are greatly increased. Since the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B07B1/28B07B1/42

Inventor 杨永柱

Owner 鞍山鞍重矿山机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com