Manifold drawing technique and special-purpose equipment thereof

A technology of drawing process and special equipment, which is applied in the field of manifold drawing process and its special equipment, can solve the problems of large local stress and difficult inspection of fillet welds, and achieve energy saving, appropriate temperature range, and not easily oxidized skin Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

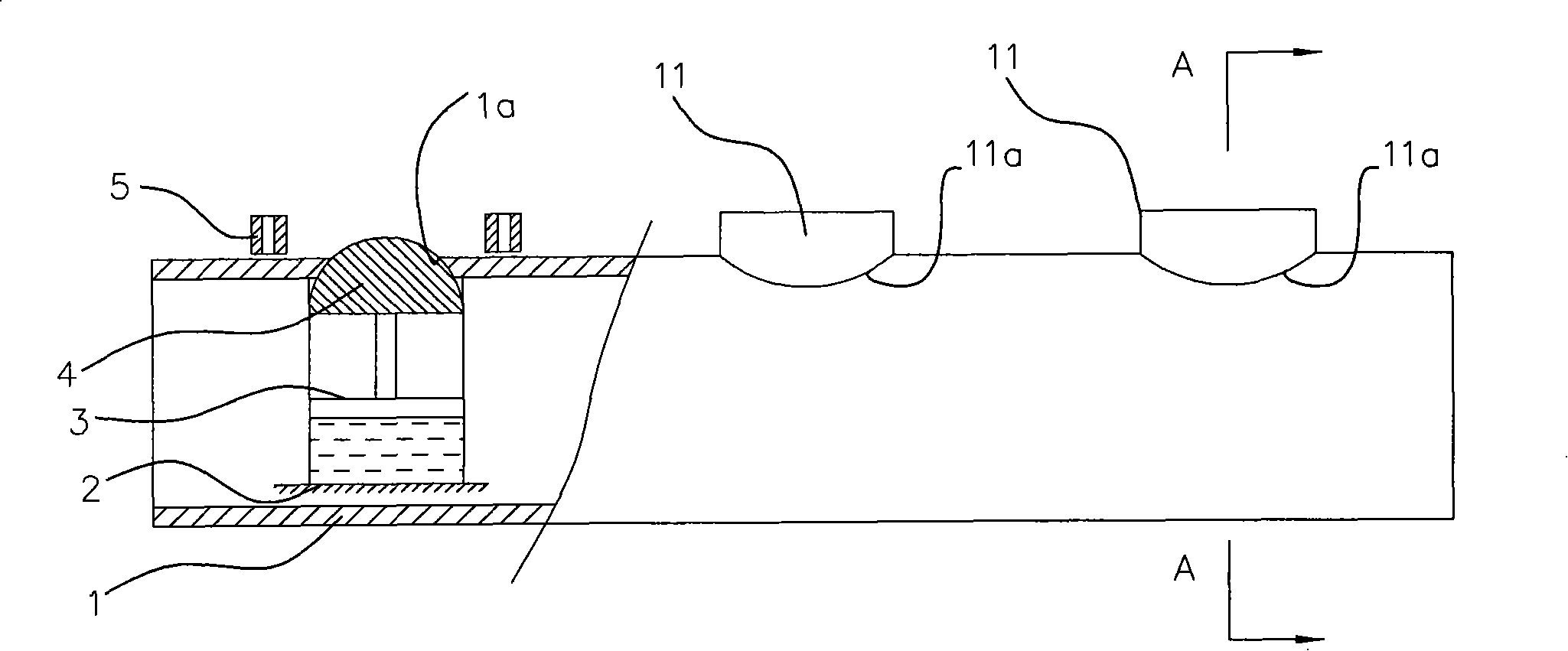

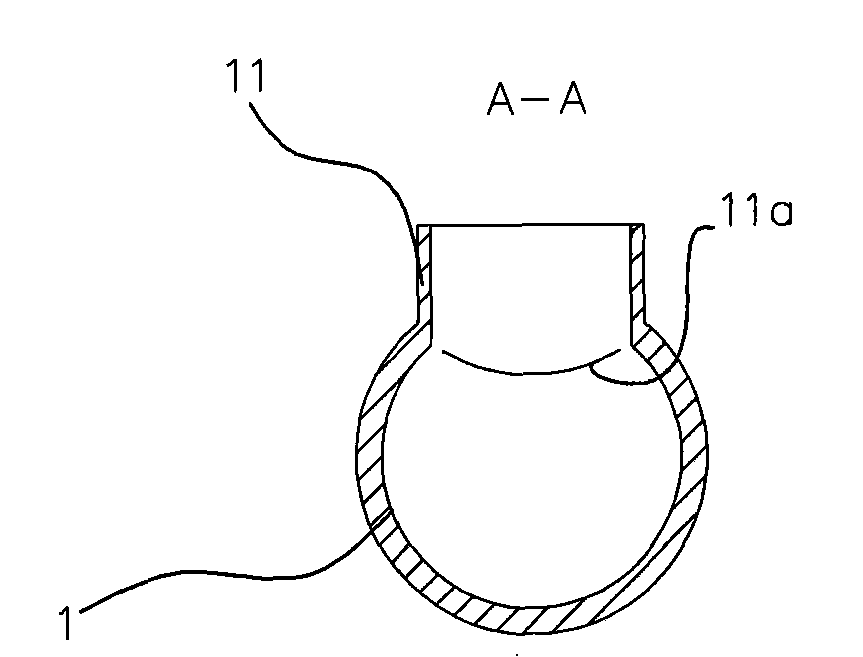

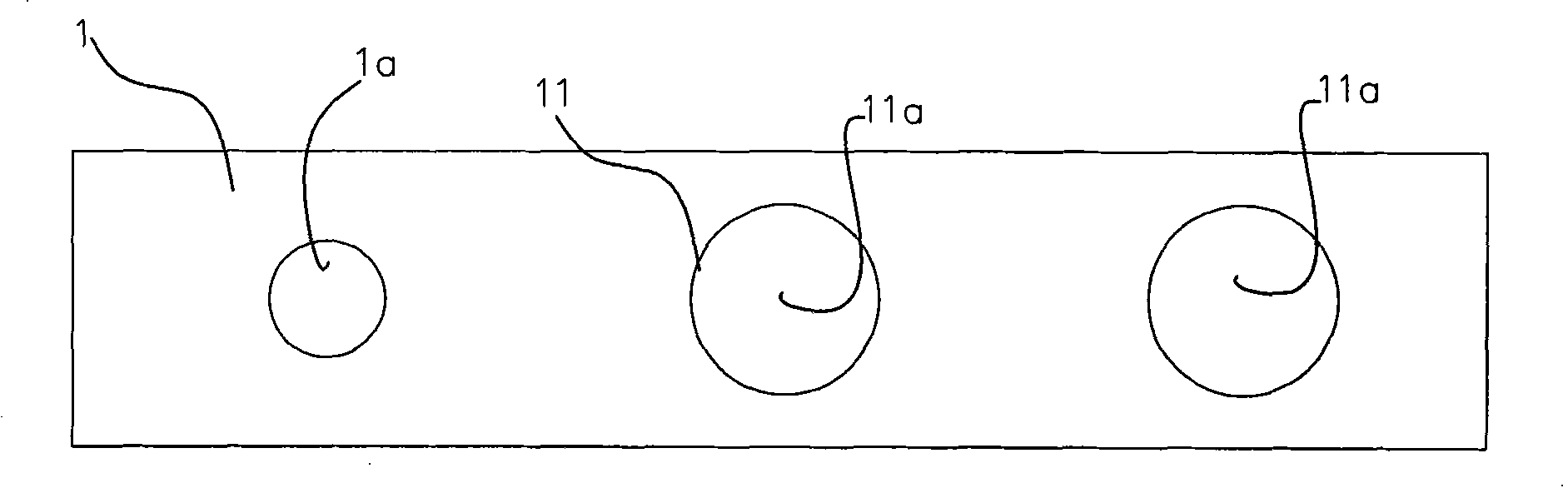

[0027] Example: refer to Figure 1 to Figure 4 , a manifold drawing process, including a material selection step: selecting a formed tube blank as the main pipe 1, which also includes the following steps:

[0028] Opening step: at least one through hole 1a is opened on the side wall of the main pipe 1; fixing step: fix the main pipe 1;

[0029] Steps for placing the drafting mold: Put a drafting mold 4 in the main pipe 1, and the drafting mold 4 is matched with the drawing machine; the drafting mold 4 is preferably a self-made irregular drafting shape. The pulling resistance is small and the pulling is uniform.

[0030] Positioning step: positioning the draft 4 on the inner hole wall of the through hole 1a;

[0031] Heating step: use the induction heater 5 to heat the through hole 1a of the main pipe 1 as the peripheral part of the body of the branch pipe 11, and the heating temperature is controlled by a thermometer, and the range is from 750°C to 1300°C;

[0032] Drawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com