Combined catalytic conversion method for biological oil and fat and mineral oil

A catalytic conversion method and bio-oil technology, which are applied in the field of combined catalytic conversion of bio-oil and mineral oil, can solve problems such as insufficient and effective use of straight-chain hydrocarbon groups, and achieve high bio-oil conversion capacity, improved flexibility, and high low-carbon olefins. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

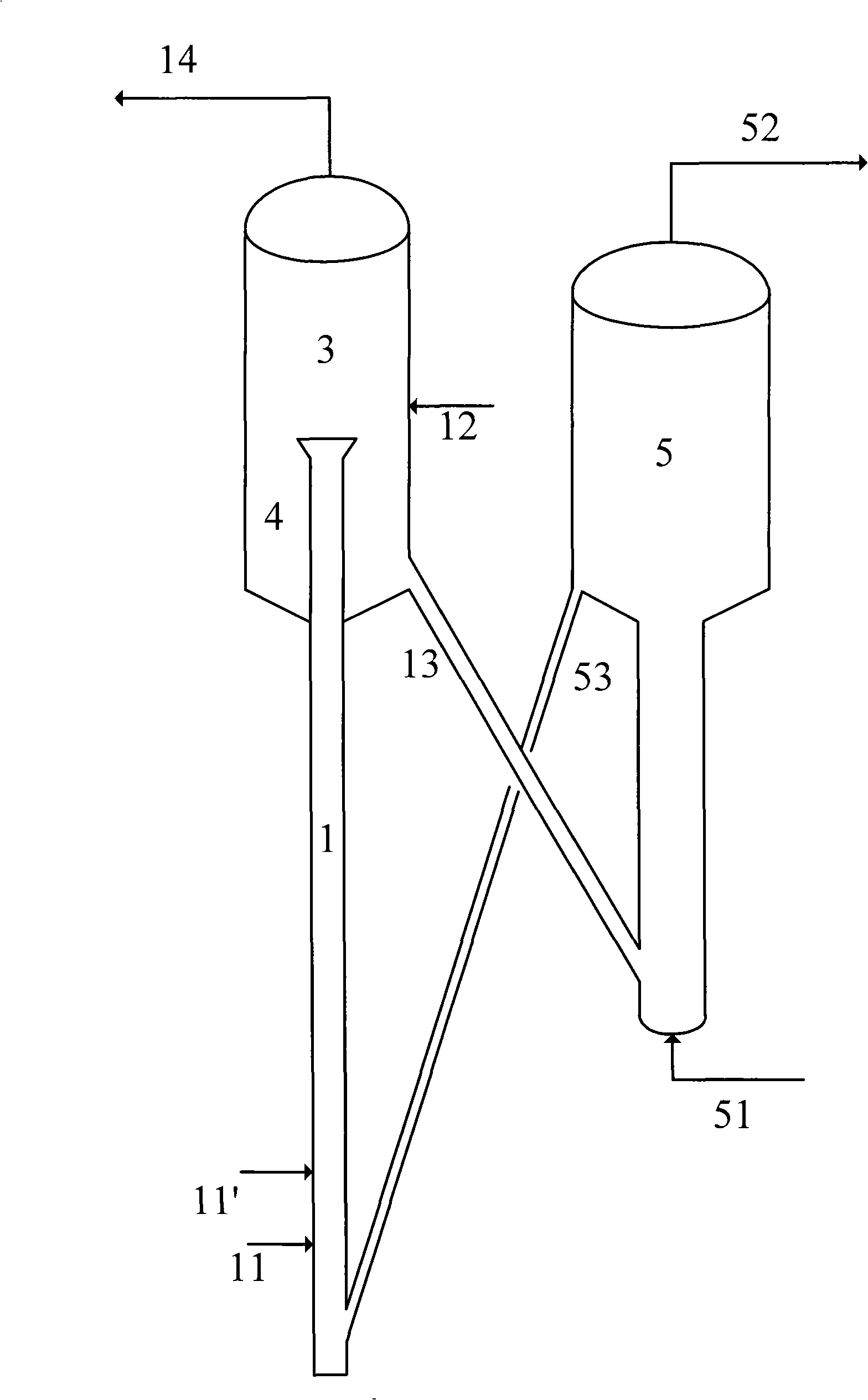

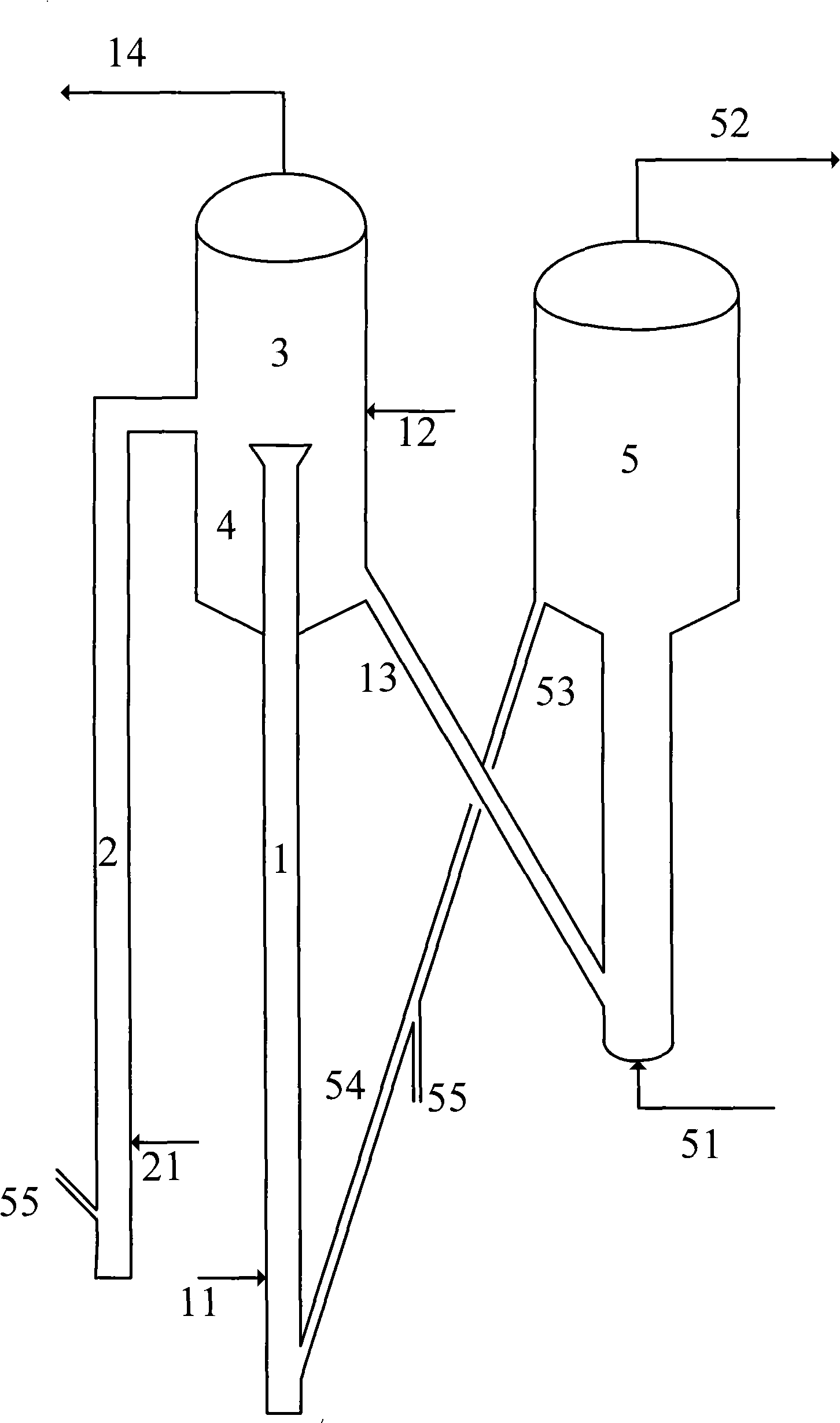

Method used

Image

Examples

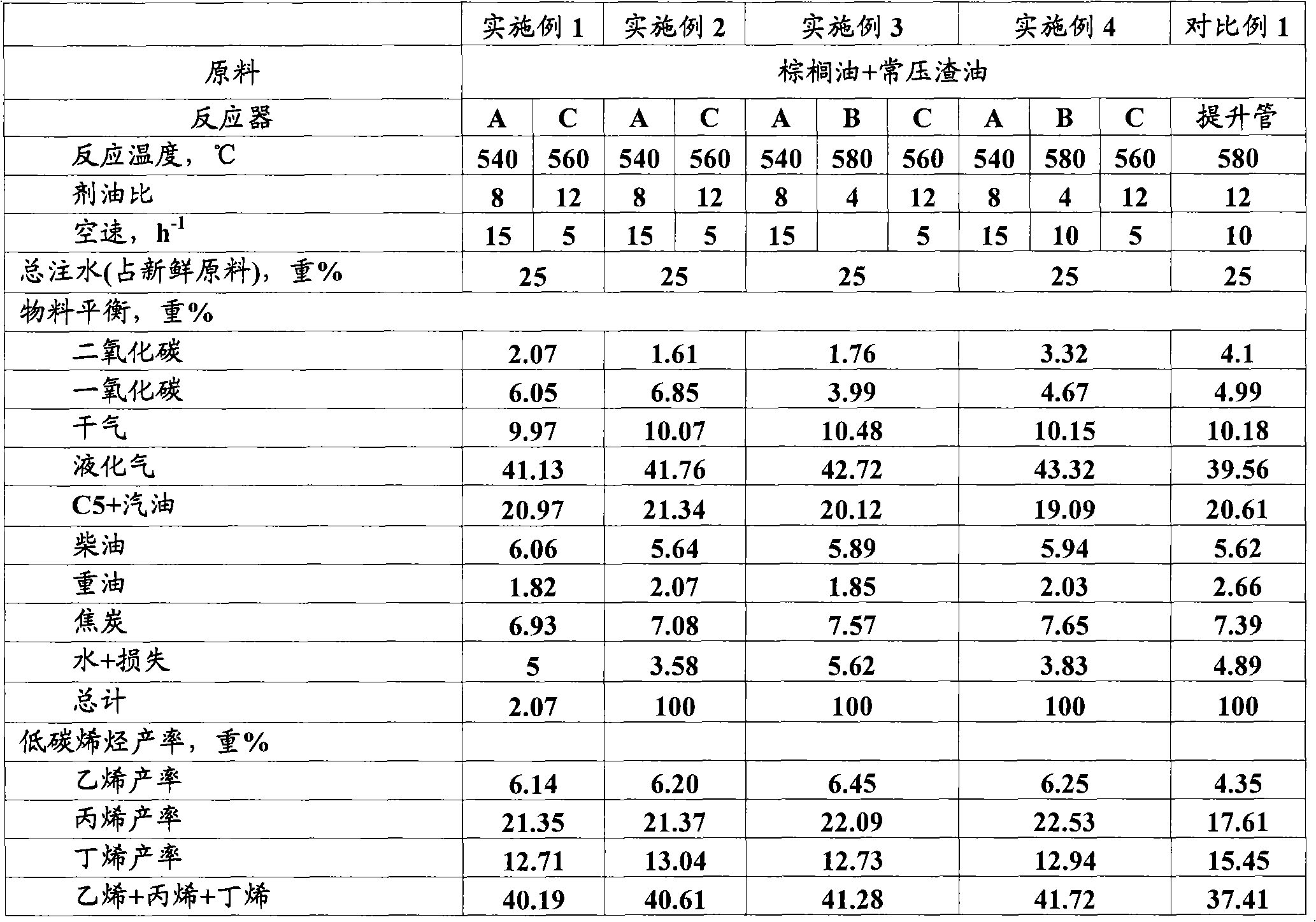

Embodiment 1~4

[0047] Examples 1 to 4 illustrate the effect of using the combined catalytic conversion method of bio-grease and mineral oil provided by the present invention.

[0048] The catalyst (containing 7% by weight of USY zeolite, 8% by weight of zeolite beta, 20% by weight of ZSM-5 zeolite, and the balance as a carrier, all based on the total weight of the catalyst) was aged at 800°C with 100% steam for 10 hours, Using a medium-scale pilot plant, the catalyst loading in the composite reactor was 60 kg.

Embodiment 1

[0049] In embodiment 1, 80% palm oil and 20% atmospheric residue only enter riser reactor 1;

Embodiment 2

[0050] In embodiment 2, 40% palm oil and 20% atmospheric residue enter the bottom of riser reactor 1, and 40% palm oil enters the middle and lower part of riser reactor 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com