Electric sewing machine

An electric sewing machine and electric motor technology, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of complex structure and high manufacturing cost of monitoring devices, achieve effective use of sewing materials, reduce product rework rates, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

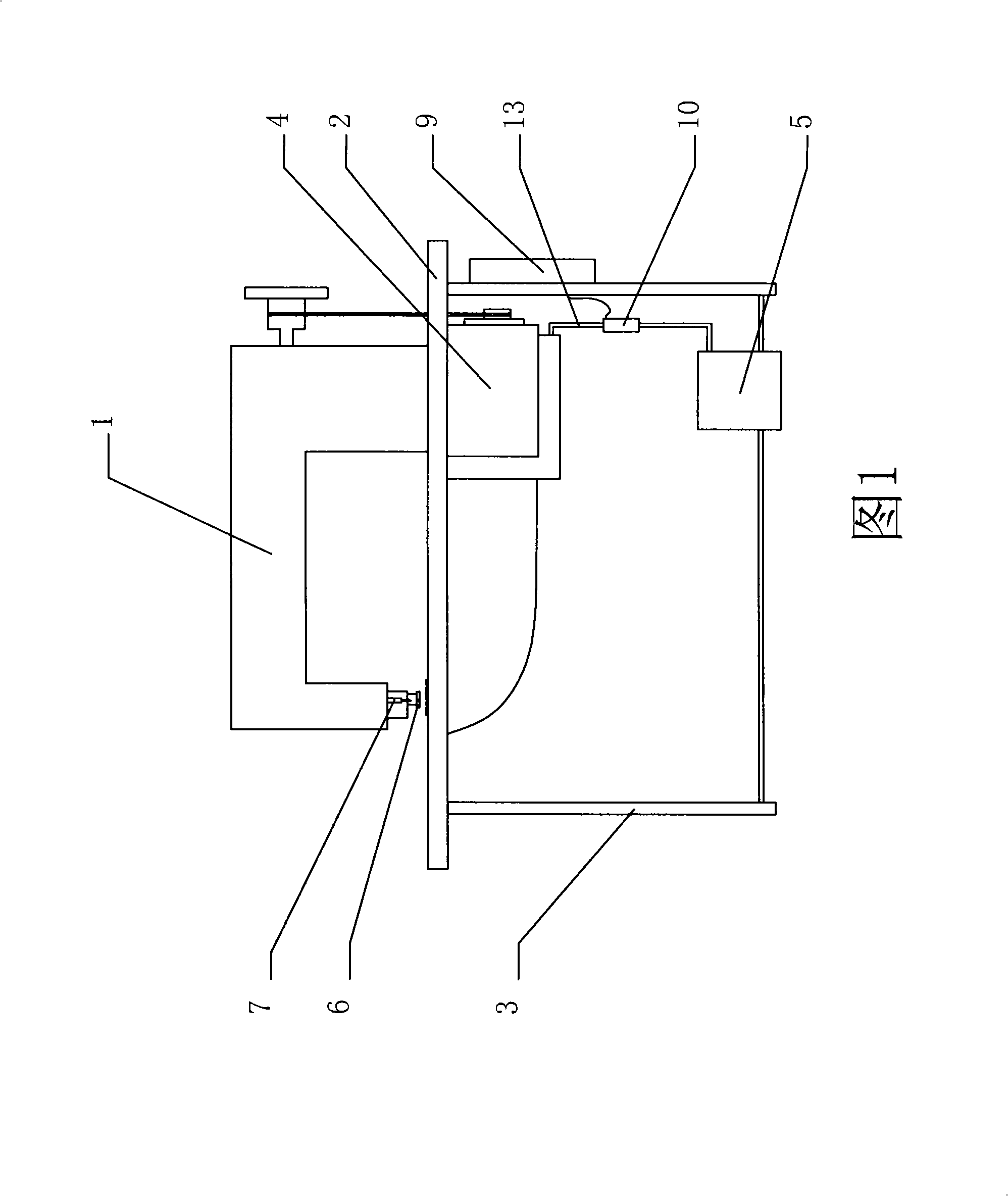

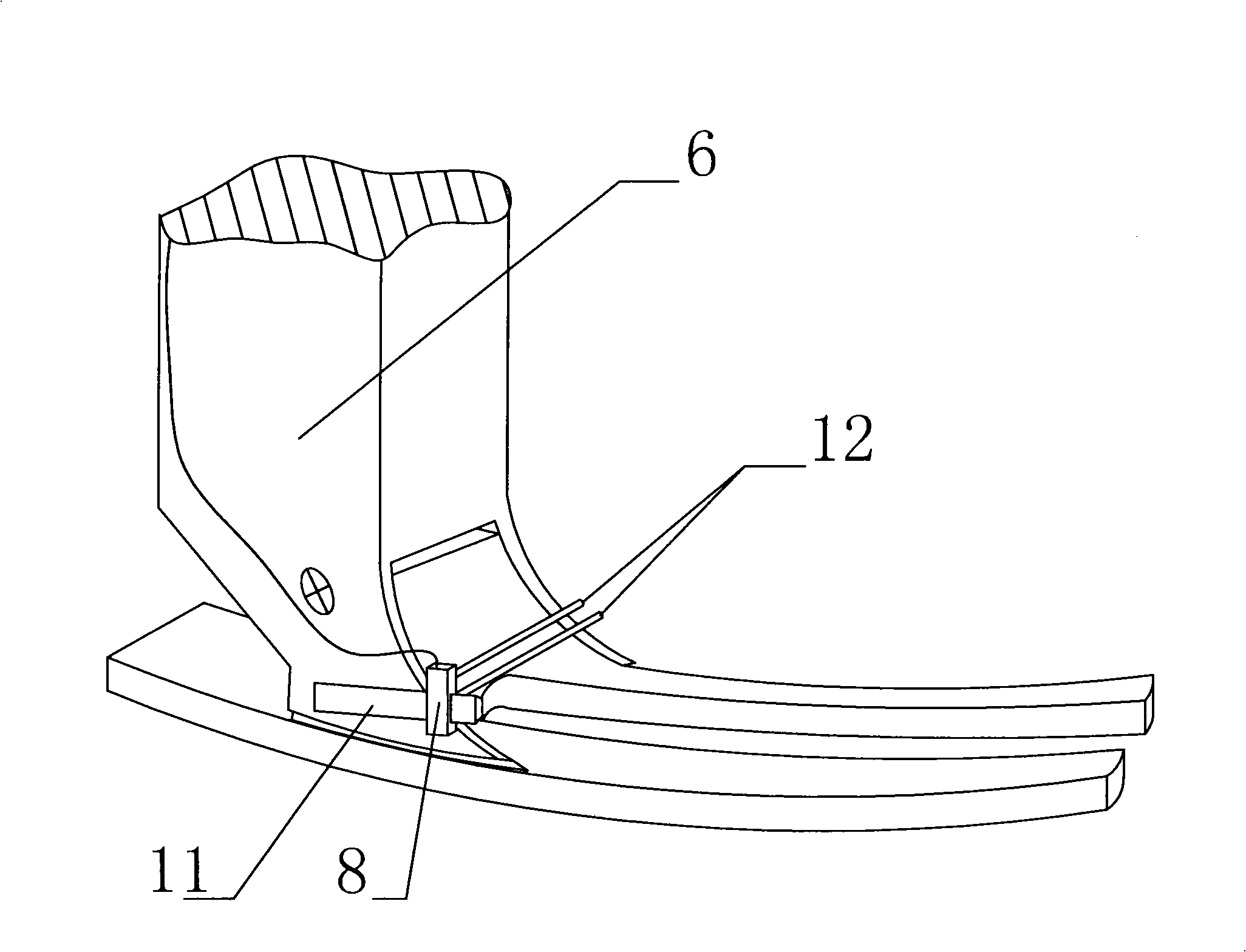

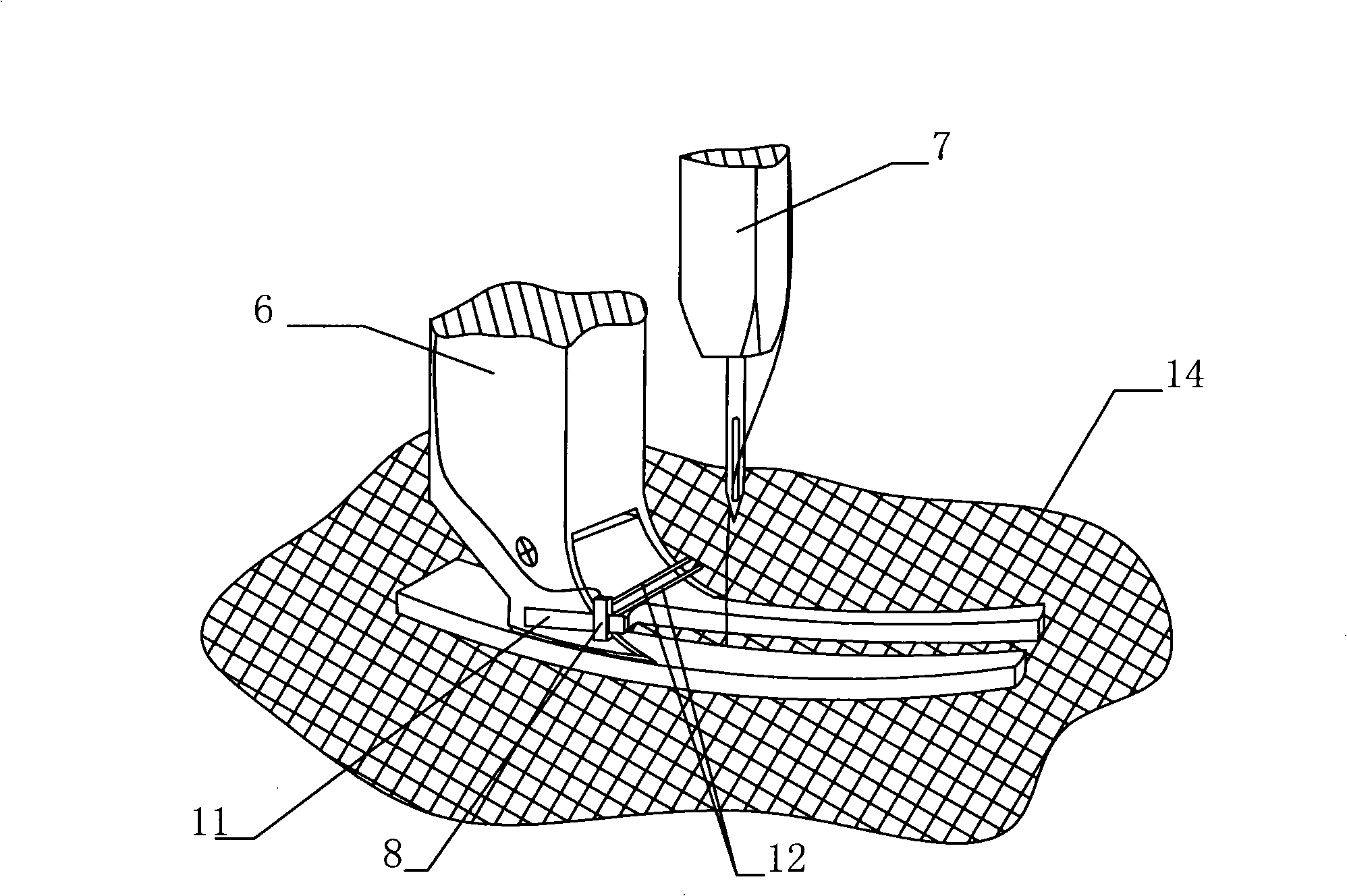

[0023] As shown in Figures 1 and 2, the electric sewing machine includes a machine head 1, a platen 2, a bracket 3, a motor 4, a pedal 5 and a bottom thread monitoring device. Platen 2 is installed on the support 3, and machine head 1 is installed on the top of platen 2, and machine head 1 is provided with a group of presser foot 6 and machine needle 7 that finish sewing work at the position relative to platen 2. Presser foot 6 can vertically move up and down, to compress the cloth 14 to be stitched up below it, and presser foot 6 is provided with a U-shaped opening. Machine needle 7 bottoms have sewing thread, just in and out from the U-shaped opening of presser foot 6 when it moves vertically up and down, and sewing thread is sewn in the cloth 14. The motor 4 is arranged on the lower part of the platen 2, on which a clutch is arranged. Pedal 5 is movably connected with motor 4 bottoms. The bottom line monitoring device includes a line position sensor 8 , a relay 9 , a capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com