Anti-leakage type photoresist bottle

A photoresist bottle and anti-drip technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of work environment damage, cleaning troubles, photoresist corrosion, etc., and achieve the effect of ensuring the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described more fully below with reference to the accompanying drawings. Typical embodiments of the invention are shown therein, but the invention can be practiced in various ways and is not limited to only the embodiments set forth herein. On the contrary, providing these embodiments can make the disclosure of the technical solution of the present invention more thorough and comprehensive, and will fully convey the protection scope of the present invention to those skilled in the art.

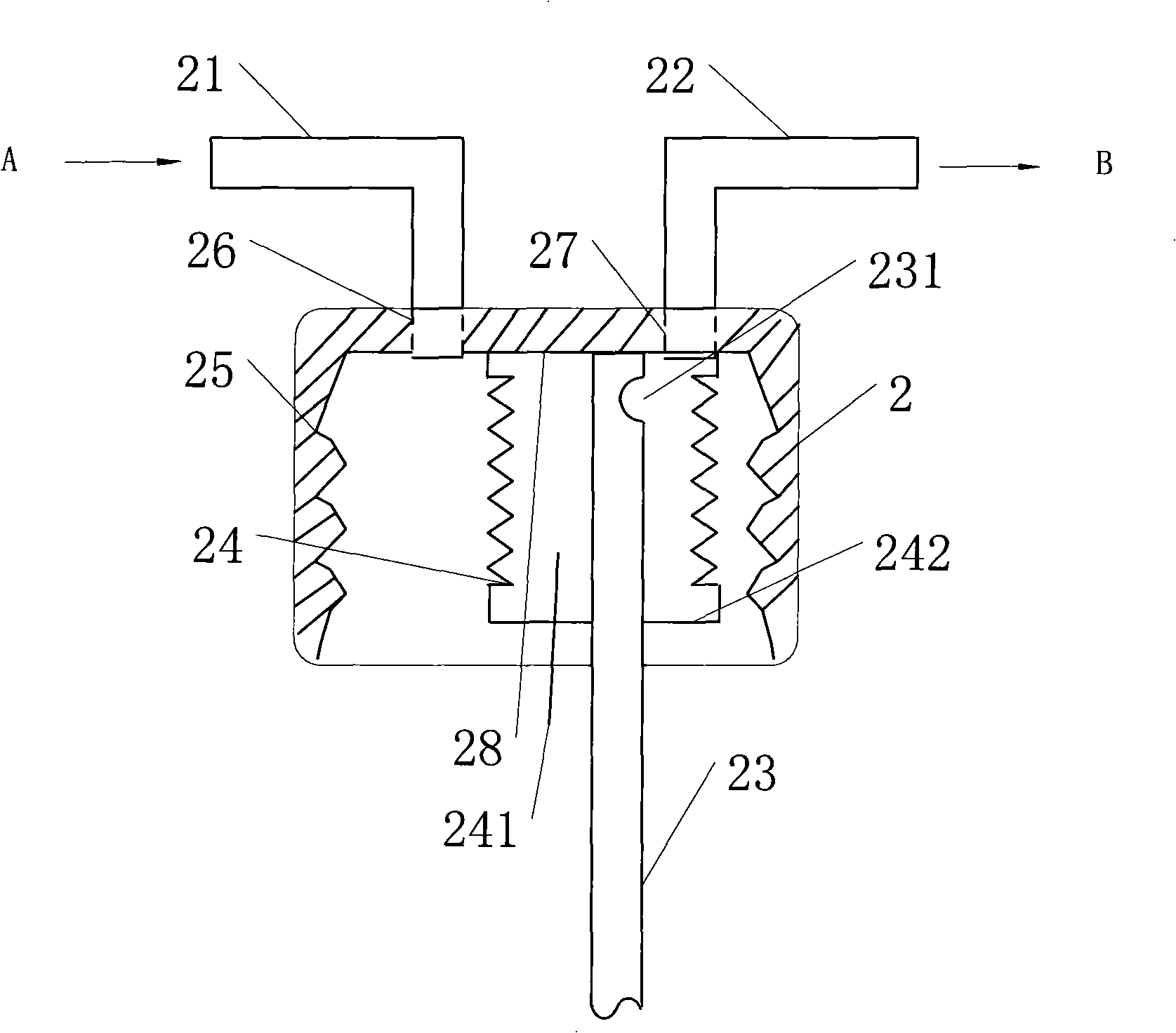

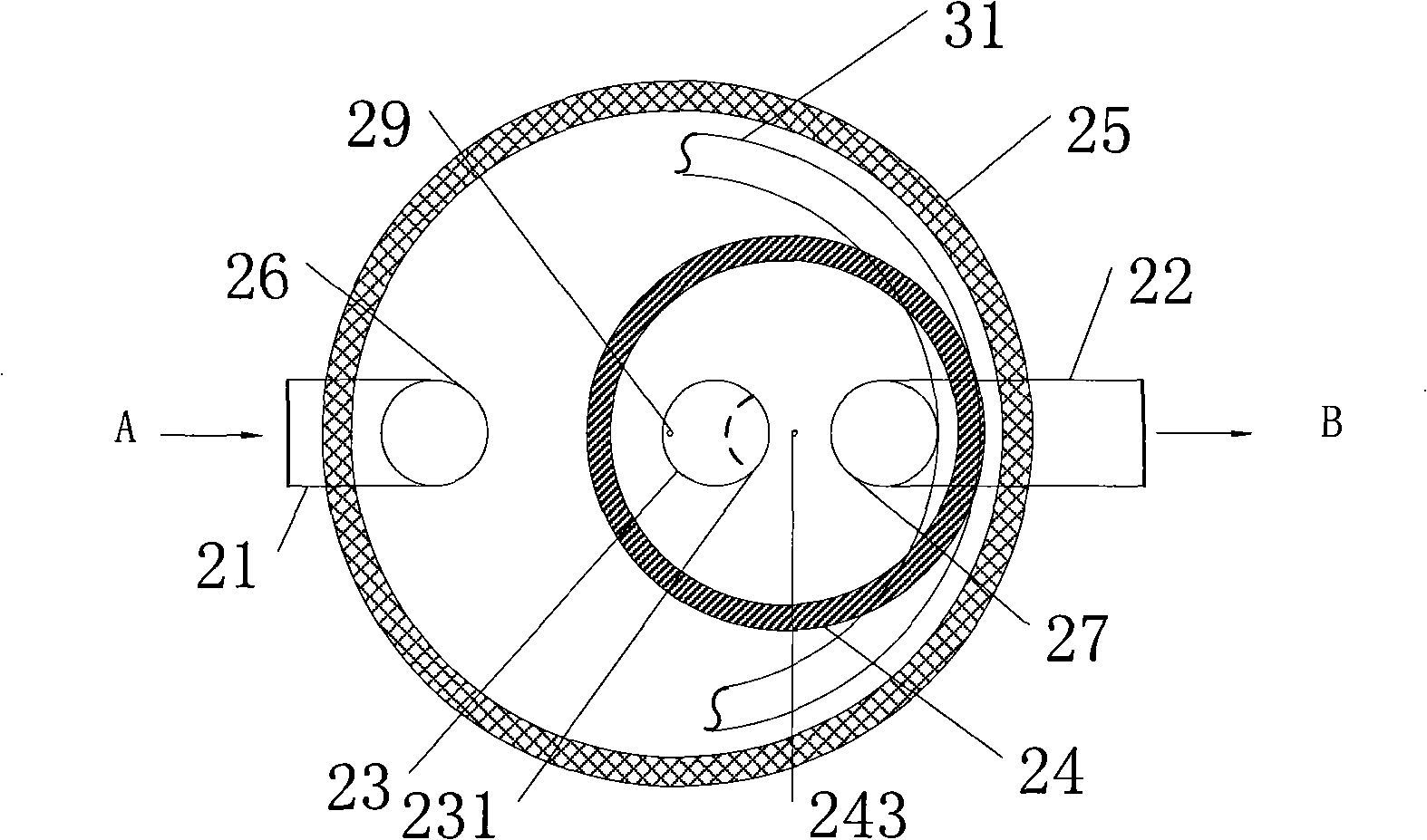

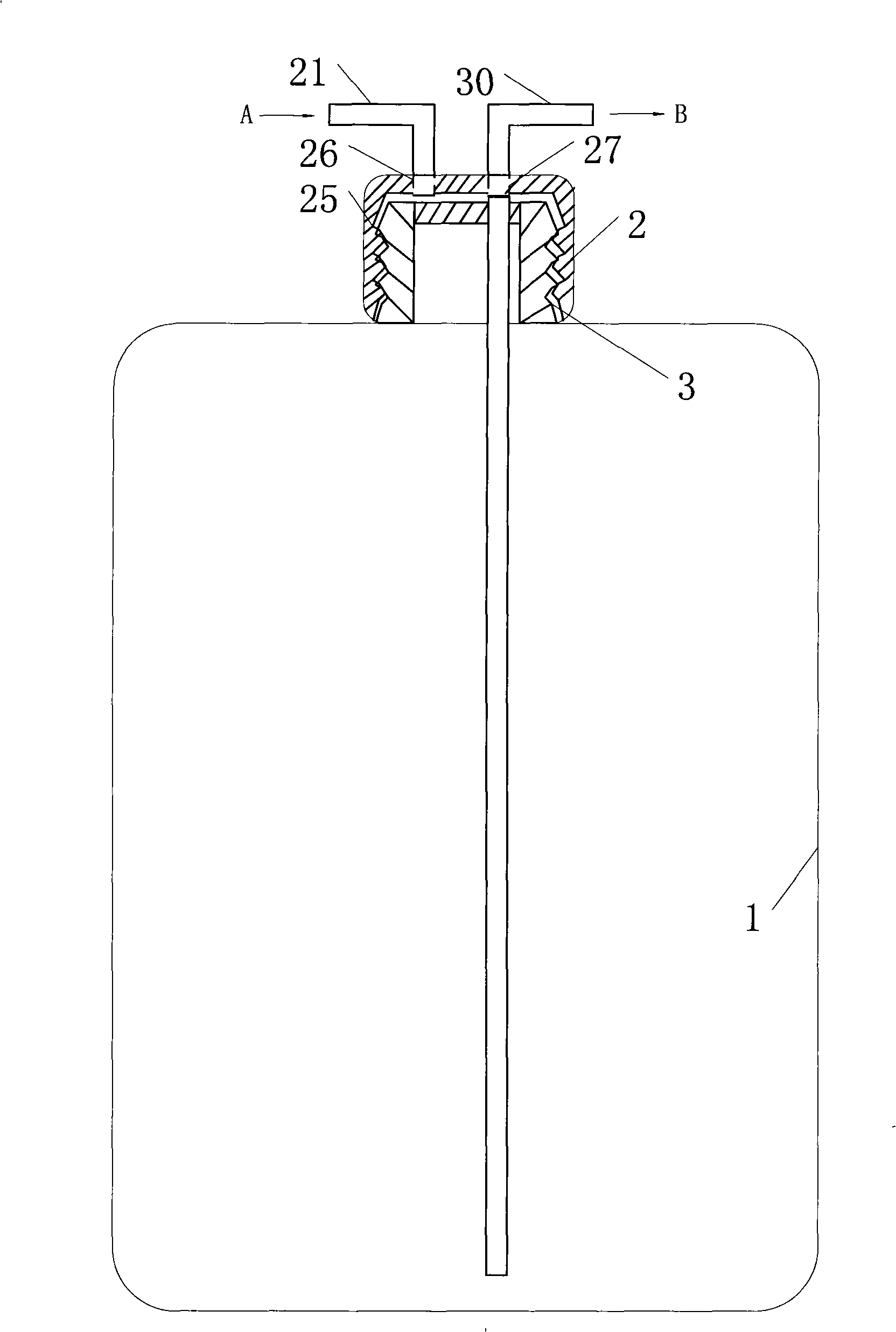

[0018] Such as figure 1 and figure 2 Shown is a schematic structural view and a schematic top view of the anti-drip photoresist bottle of the present invention. The anti-drip type photoresist bottle includes a bottle body 1, a bottle cap 2, an air inlet pipe 21, a liquid outlet pipe 22, a liquid suction pipe 23 and a threaded hose 24, and the air inlet pipe 21 passes through the inlet pipe 2 on the bottle cap 2. The pressure ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com