Order reduction modeling method of micro electro-mechanical system containing considerable input ports

A micro-electromechanical system and input port technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

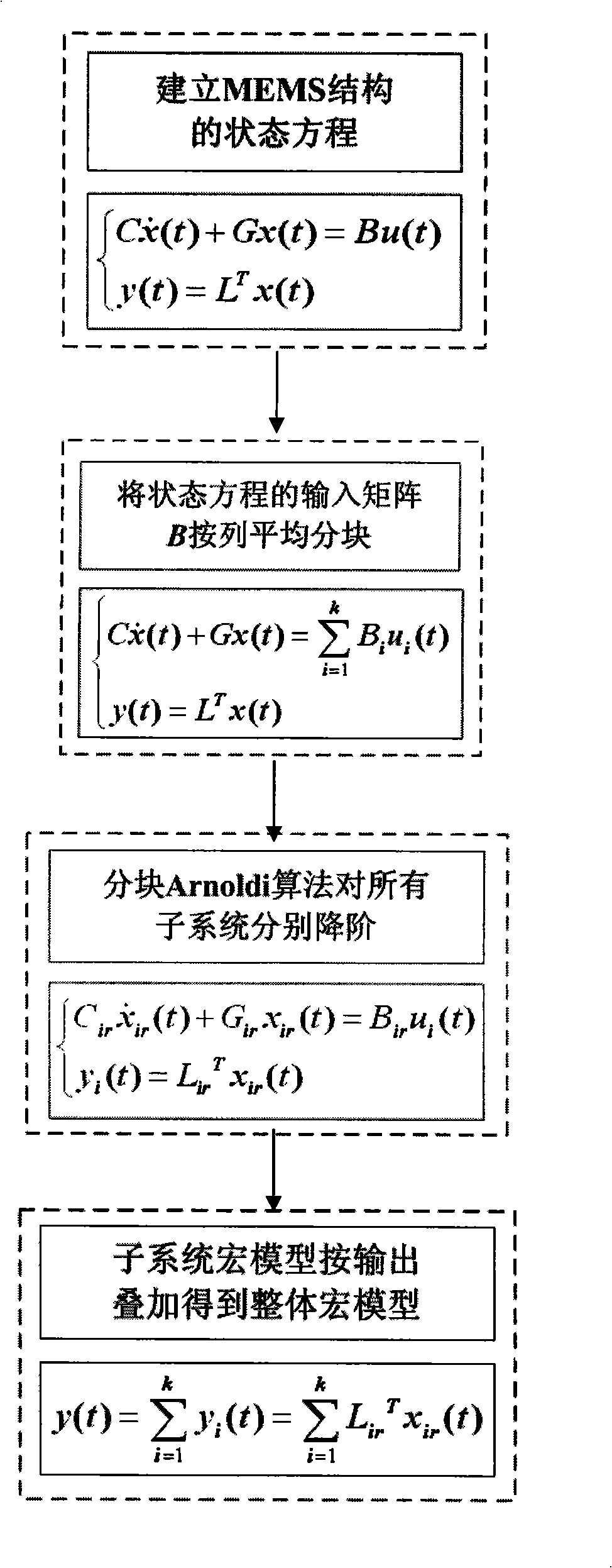

Method used

Image

Examples

Embodiment Construction

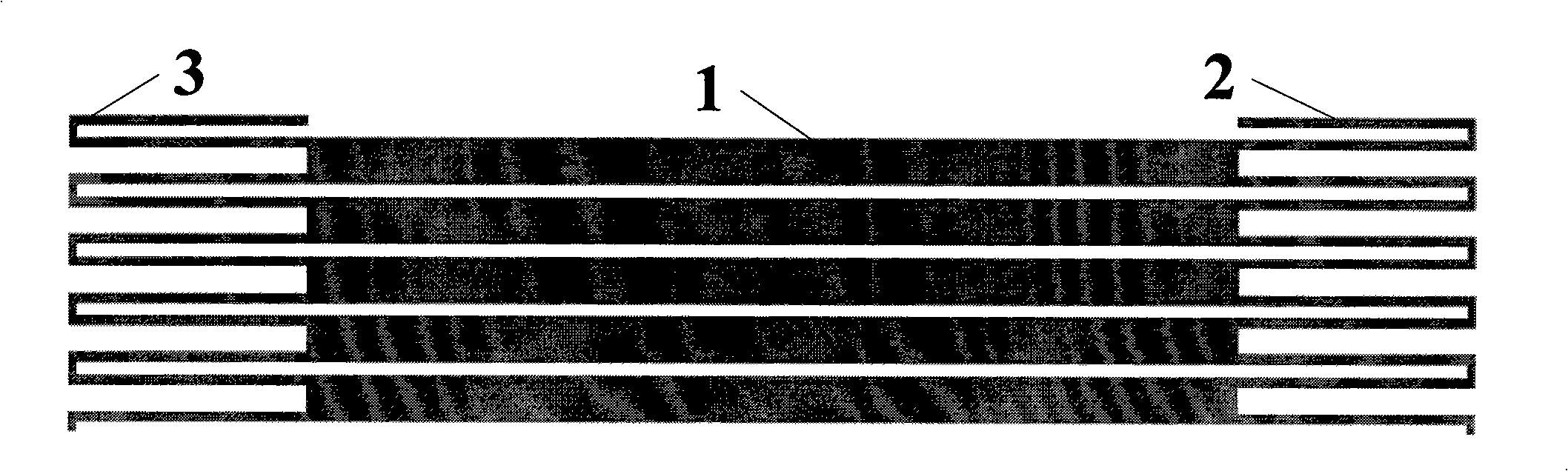

[0039] The present invention will be further described below in conjunction with a macro model extraction process of a variable-section folded beam. The variable cross-section folded beam is a typical structure in MEMS design, and it is widely used in the design of MEMS devices such as micro accelerometers, micro gyroscopes, and micro gratings. Refer to attached figure 2 , its structure is made of five thick beams 1, twenty-two thin beams 2 and twelve longitudinal beams 3. The macro model extraction process of variable cross-section folded beam includes the following steps:

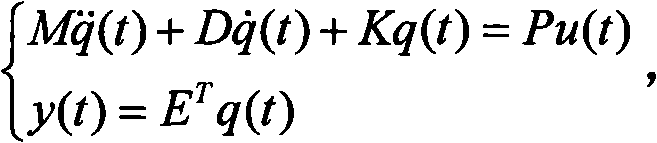

[0040] Step 1: Use 3D modeling tools to establish the geometric model of the variable cross-section folded beam. Use the finite element software ANSYS to select the beam188 material and Solid92 element for modal analysis. The finite element model contains two constraint surfaces and 7718 nodes, including Two input and output nodes, since each node of beam188 contains 6 degrees of freedom, that is, tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com