Wound electric double-layer capacitor

An electric double layer capacitor, wound type technology, applied in the manufacture of hybrid/electric double layer capacitors, electrolytic capacitors, capacitors, etc., can solve the problem of less deterioration of characteristics, and achieve the effect of less deterioration of characteristics and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0060] Next, the first embodiment will be described.

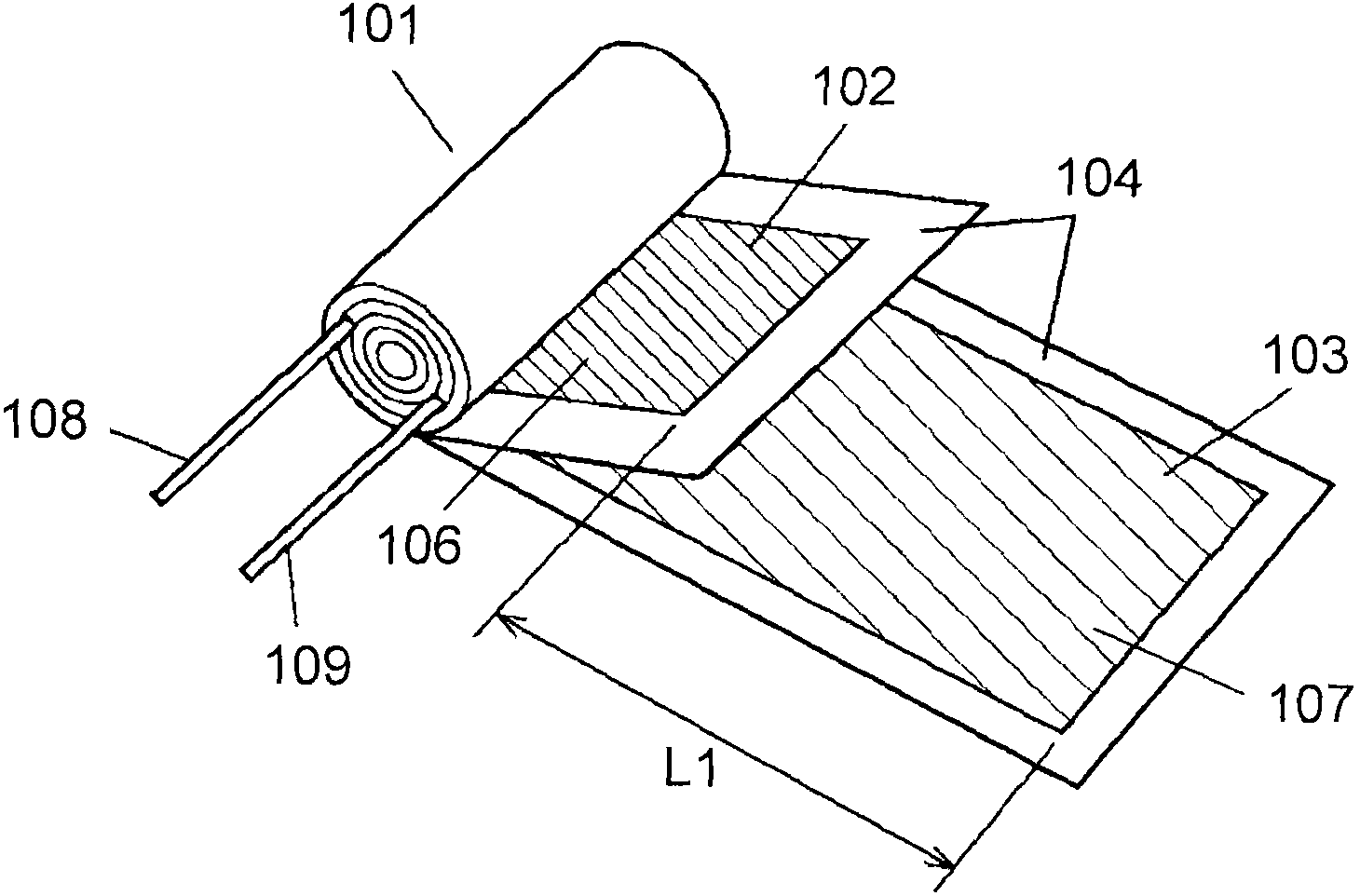

[0061] figure 1 It is a developed perspective view showing the configuration of a capacitor element used in the wound electric double layer capacitor of the first embodiment. figure 1 Among them, the capacitor element 101 is wound with the separator 104 interposed between the anode electrode 102 and the cathode electrode 103 .

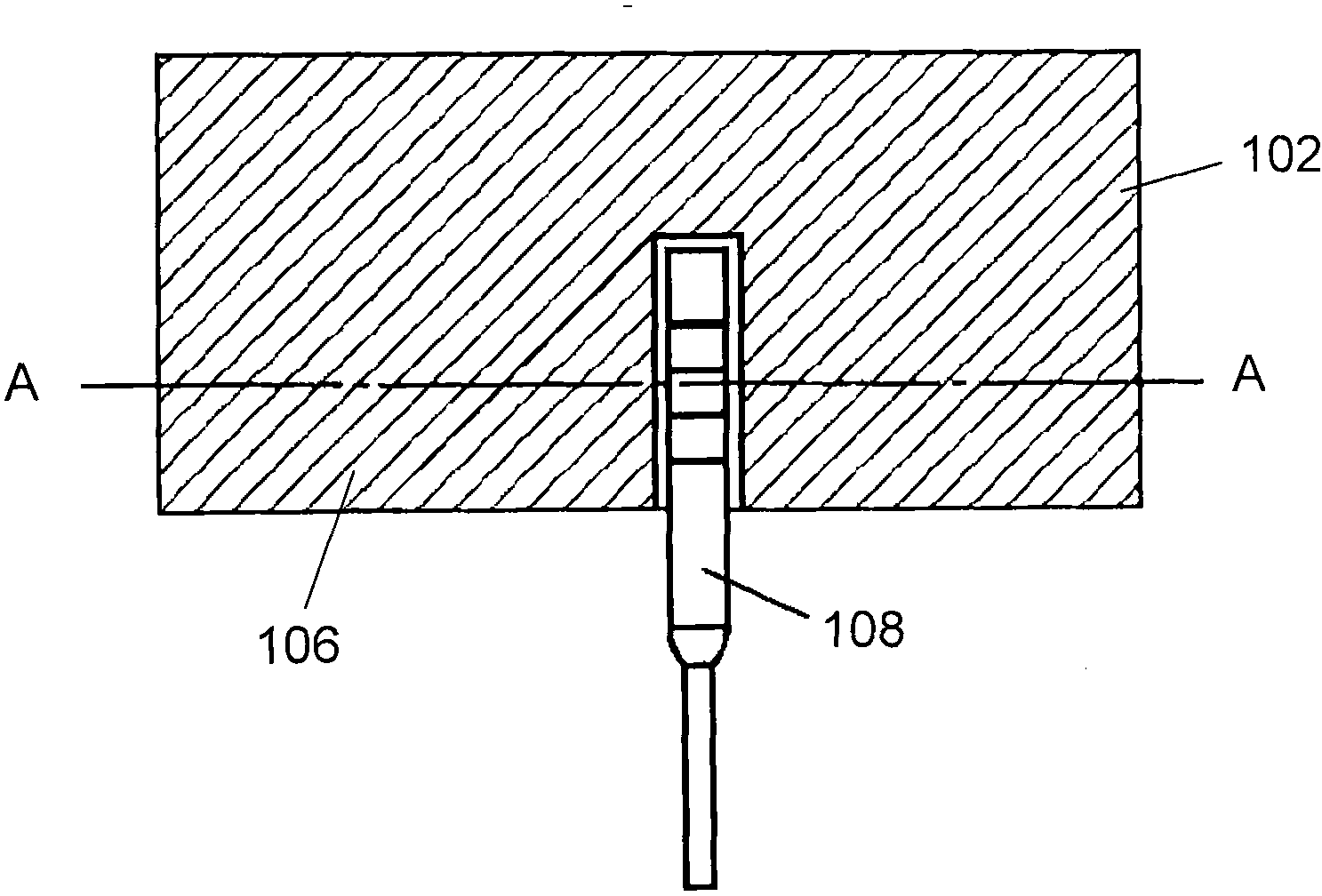

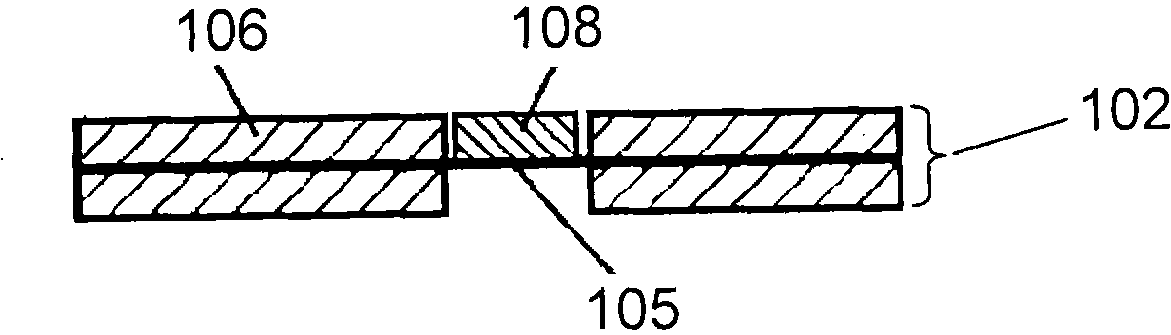

[0062] In addition, the above-mentioned anode electrode 102 and cathode electrode 103 are formed by forming polarizable electrode layers 106 or 107 respectively on both surfaces of a current collector 105 composed of a metal foil described later. Furthermore, the anode electrode 102 and the cathode electrode 103 are connected to an anode lead 108 and a cathode lead 109 , respectively. The details of the connection of the anode lead 108 and the cathode lead 109 are as follows Figure 2A , Figure 2B As shown, a part of the polarizable electrode layer 106 formed on the anode electrode 102 (the ...

no. 1 example

[0072] As a current collector composed of metal foil, a high-purity aluminum foil (AL: 99.99% or more) with a thickness of 30 μm was used, and electrolytic etching was performed in a hydrochloric acid-based etching solution to roughen the surface of the aluminum foil.

[0073] Next, polarizable electrode layers were formed on both sides of the aluminum foil. The polarizable electrode layer is formed by mixing phenolic resin-based activated carbon powder with an average particle size of 5 μm, carbon black with an average particle size of 0.05 μm as a conductivity-imparting agent, and dissolved CMC water-soluble binder solution, and kneaded fully with a kneader, then add a dispersion solvent of methanol and water little by little, and knead again to make a slurry with a specified viscosity. Next, this slurry was applied on the surface of the aluminum foil, and dried in the air at 100° C. for one hour to form a polarizable electrode layer.

[0074] Next, the aluminum foil formed...

no. 2 example

[0080] In the first embodiment above, if image 3 The anode electrode and the cathode electrode are arranged as shown, and the width W2 of the cathode electrode is set to 44 mm with respect to the width W1 (40 mm) of the anode electrode. The rest is the same as that of the first embodiment to produce a wound electric double layer capacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com