Superfine back taper hole spark-erosion machining electrode movement guide mechanism

A technology of guiding mechanism and reverse taper hole, which is applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of affecting the flow coefficient of the nozzle hole, adversely affecting the fuel injection efficiency, and improving the efficiency, and achieve the effect of uniform loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

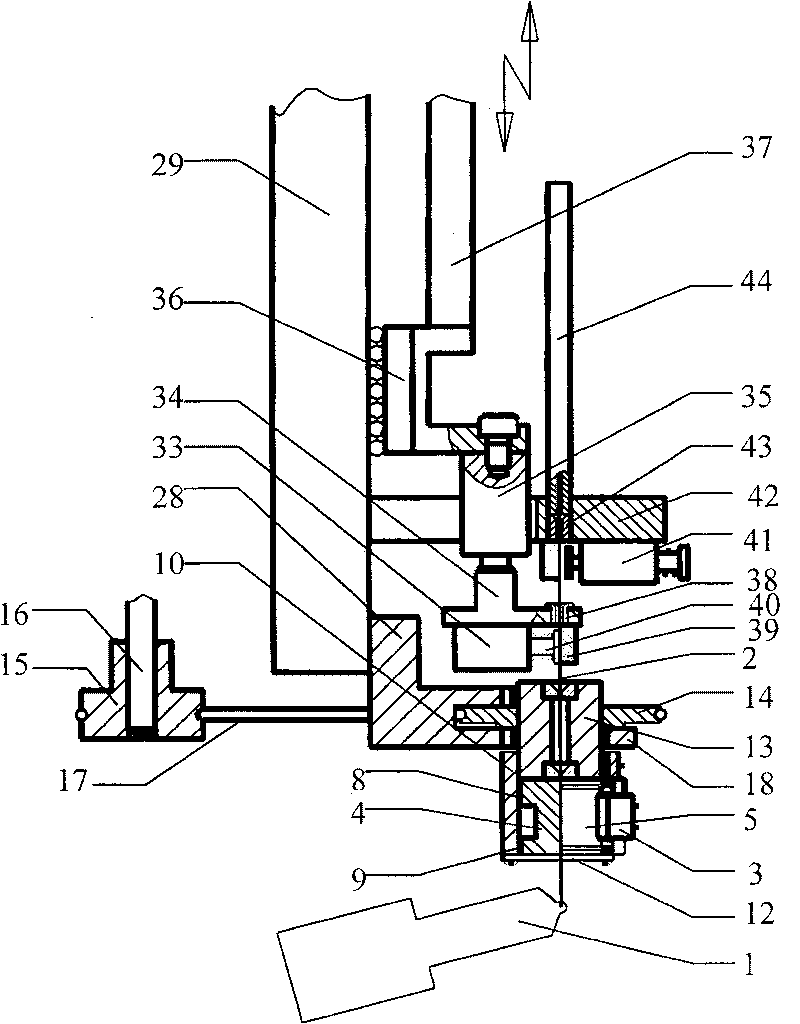

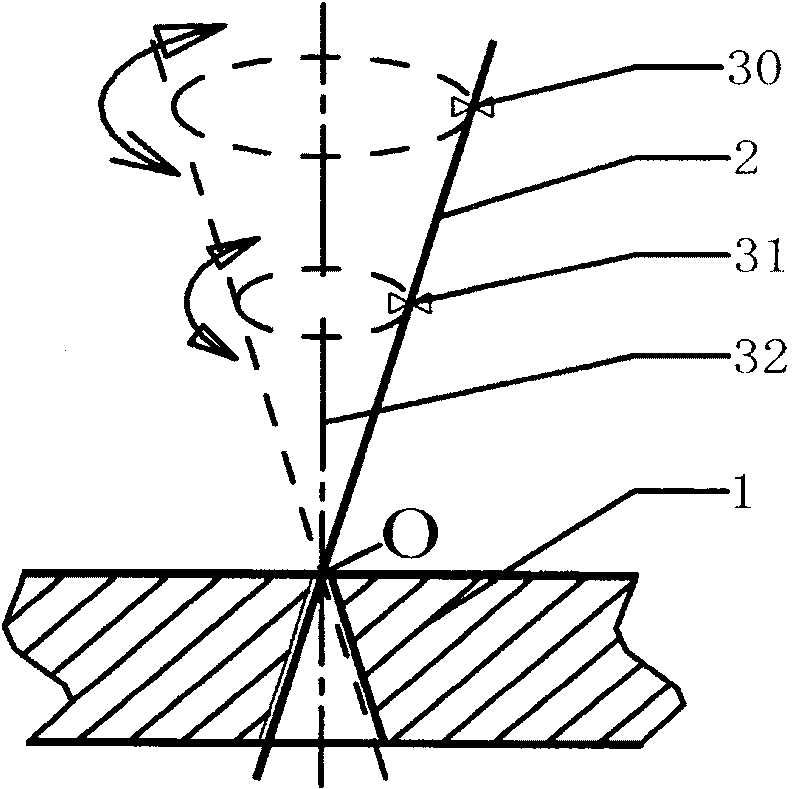

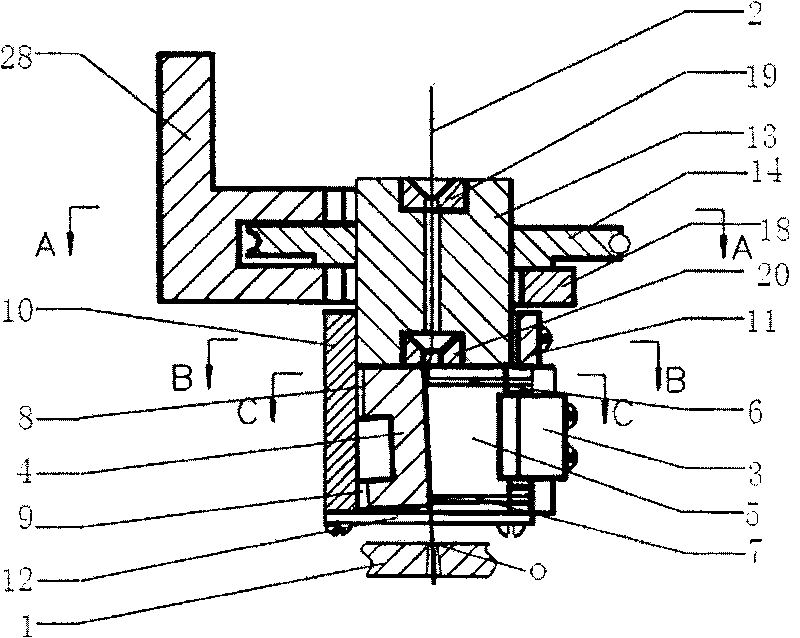

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] figure 1 Shown is the embodiment of the present invention, the micro electrode servo drive mechanism and the micro electrode loss automatic compensation mechanism of the micro electric discharge machining device to form the micro back taper hole electric discharge machining device.

[0025]In this device, the micro electrode loss automatic compensation mechanism is mainly composed of a normally open wire clamping mechanism 41 and a normally closed wire clamping mechanism 33, and the normally closed wire clamping mechanism 33 is located between the normally open wire clamping mechanism 41 and the fine inverted taper hole EDM electrode. between motion-guiding mechanisms. The fine electrode wire 2 is clamped by a normally closed clamp wire mechanism 33, and the normally closed clamp wire mechanism 33 is affixed to the lower end of the connecting rod 35 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com