Ultra-high pressure sea water pressure balance valve

An ultra-high pressure, balanced valve technology, applied in the direction of balance valve, lift valve, valve device, etc., can solve the problems of inability to seal with sea water, limited application scope, etc., and achieve the effect of unlimited application scope and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

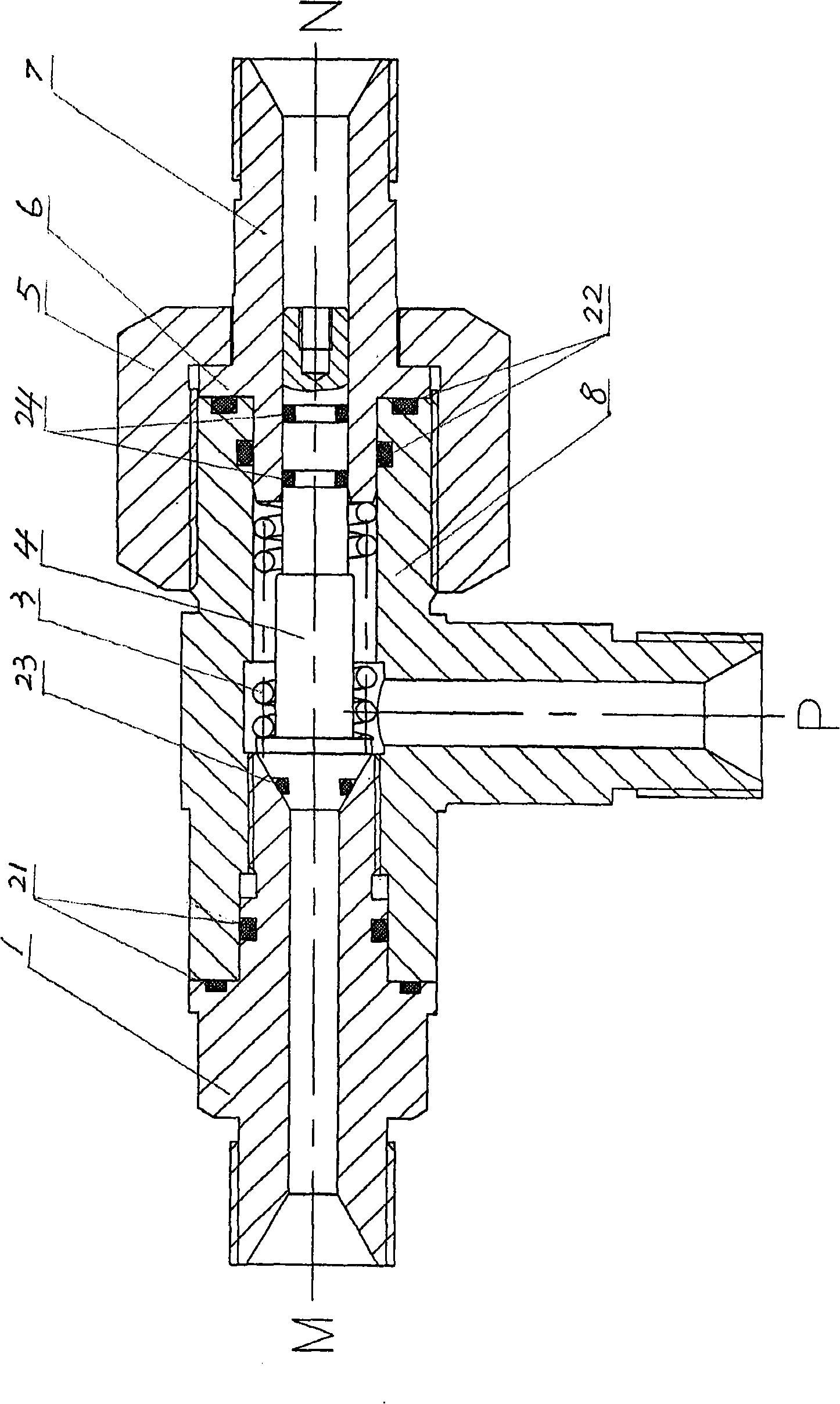

[0012] As shown in the drawings, the ultra-high pressure seawater pressure balance valve of the present invention includes a valve seat 1 , a valve body 8 and a valve sleeve 7 . The valve body 8 is a T-shaped tee. Both the valve seat 1 and the valve sleeve 7 are tubular, and the outer diameter of a section of their inner end is smaller than that of the outer section, thereby forming a step in the middle of their outer circle, and they respectively extend into the two ends on the same axis of the valve body 8; Grooves are processed on their steps and on the outer circle inside the steps, and rubber sealing rings 21 and 22 are respectively embedded in the grooves. Through the sealing rings, the gap between the valve seat 1 and the valve body 8 and between the valve body 8 and the valve sleeve are realized. 7 between the seals. The inner end of the valve seat 1 and the end connected to the valve body 8 are respectively processed with external and internal threads, and the two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com