On-line temperature measurement method and device for cable joint of high-voltage plant

A technology for cable joints and high-voltage equipment, used in measuring devices, using electrical devices, thermometers with electrical/magnetic components that are directly sensitive to heat, etc. It is difficult to install and implement problems, so as to improve work reliability, solve the problem of online temperature measurement, and achieve the effect of high work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

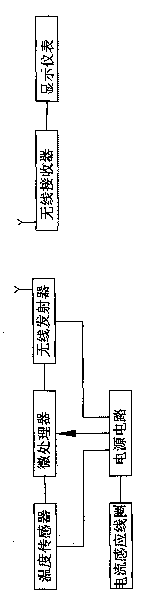

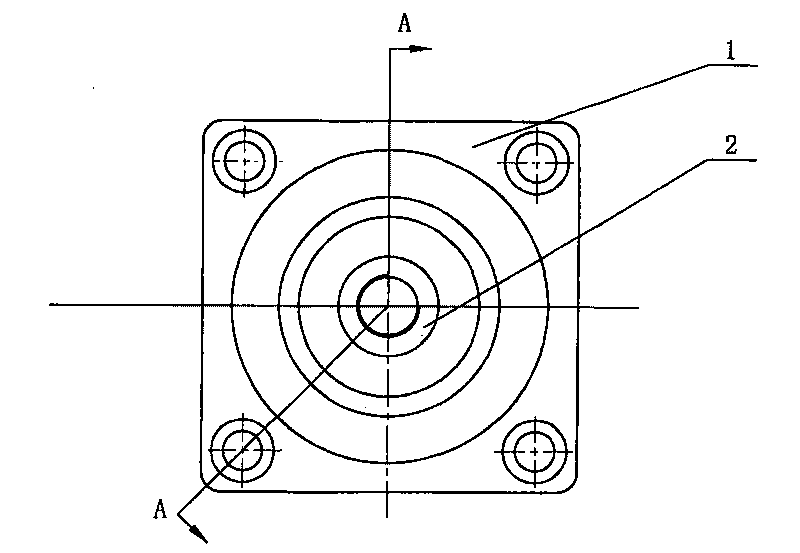

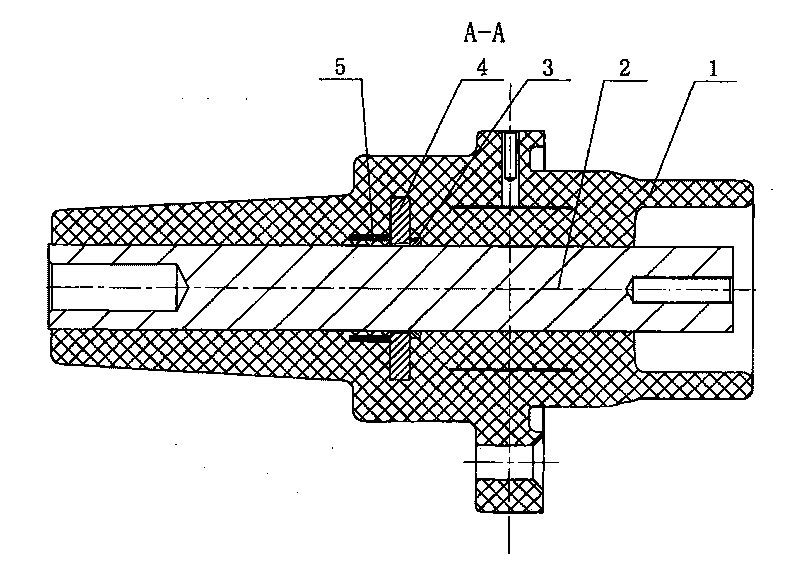

[0016] See figure 1 As shown, the online temperature measurement method of the high voltage equipment cable joint of the present invention,

[0017] (1) Attach the temperature sensor to the surface of the metal conductor, and the current induction coil with an insulating surface layer is set on the metal conductor, and at the same time, the power circuit, microprocessor and wireless transmitter are installed on the metal conductor through the circuit board, The temperature sensor, current sensing coil and circuit board are all sealed within the insulator.

[0018] (2) Write the digital identification codes of the three output terminals of the tested cable connector into the memories of the respective microprocessors respectively.

[0019] (3) Three metal conductors encapsulated by insulating materials are respectively installed at the output end of the three-phase cable of the high-voltage equipment. When the metal conductors flow a current greater than 15A, the current induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com