Fluorescent lamp tube with mirror face reflection coating

A specular reflection, fluorescent lamp technology, applied in the field of fluorescent lamps, can solve the problems of inability to take into account the light source point and surface, low reflectivity, etc., and achieve the effect of saving reflective processes and materials and improving lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments are further described below in conjunction with the accompanying drawings.

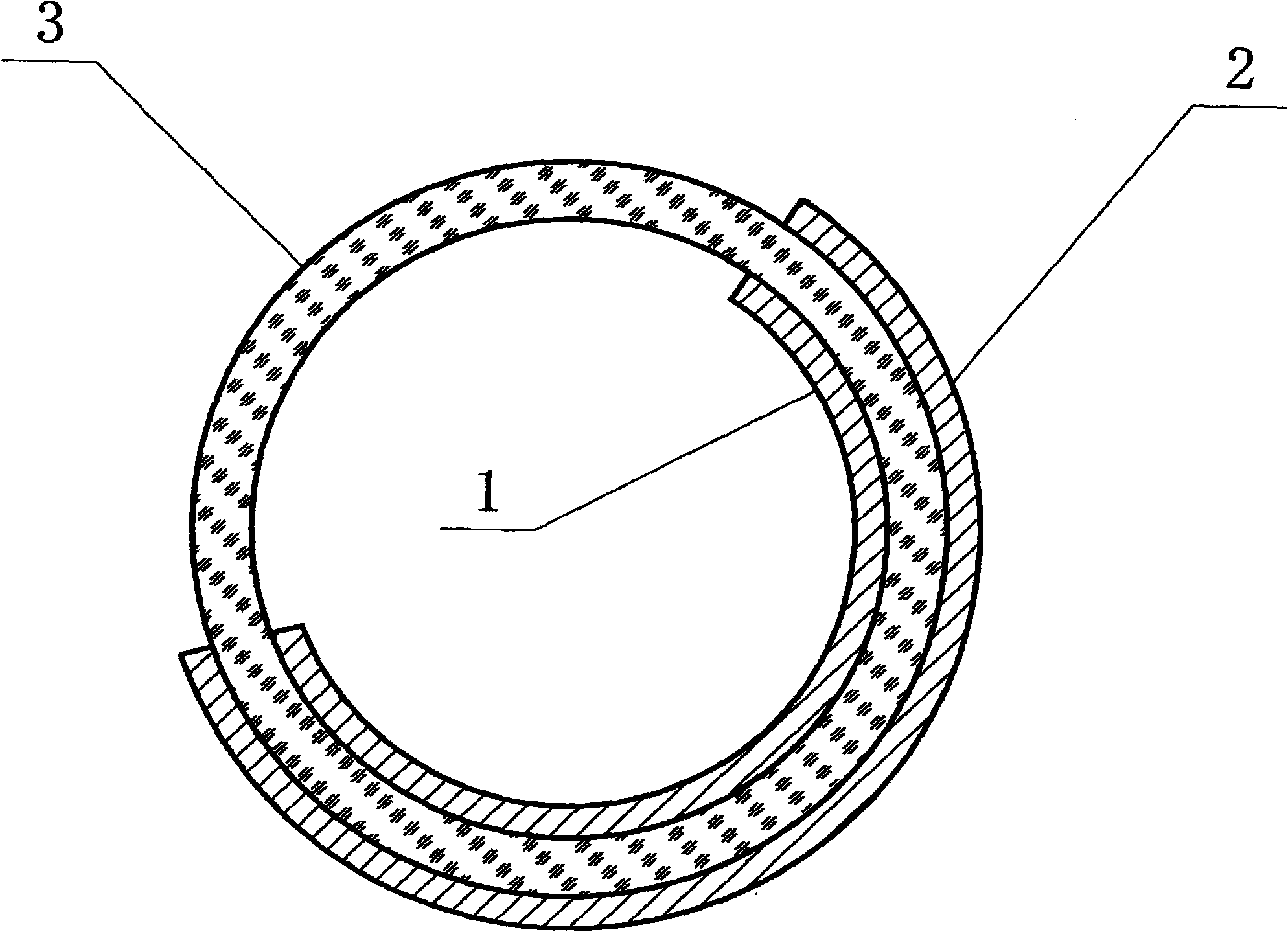

[0011] refer to figure 1 , 1-high reflective film, 2-high reflective film, 3-fluorescent glass tube. As shown in the figure, the innovative point of the present invention is that the inner and outer walls of the fluorescent lamp glass tube 3 are coated with one to multiple layers of high reflection film, and it is also possible to coat the high reflection film 1 only on the inner wall of the lamp tube or only on the outer wall of the lamp tube. It is coated with a high reflective film 2. The high reflection film is coated with vacuum aluminum coating or vacuum titanium coating. The area to be coated should be determined according to the geometric size of the lamp tube. And to achieve the effect of specular reflection, this improves the lighting effect of the light and saves the reflective process and materials on the light stand and the light fixture. It solves the problem t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com