Fluid compressor with aerostatic bearing, control system of a compressor with aerostatic bearing and method of controlling a compressor with aerostatic bearing

A compressor, statics technology, applied in the components, bearings, pump control, etc. of pumping devices for elastic fluids, can solve the problems of cost, production and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

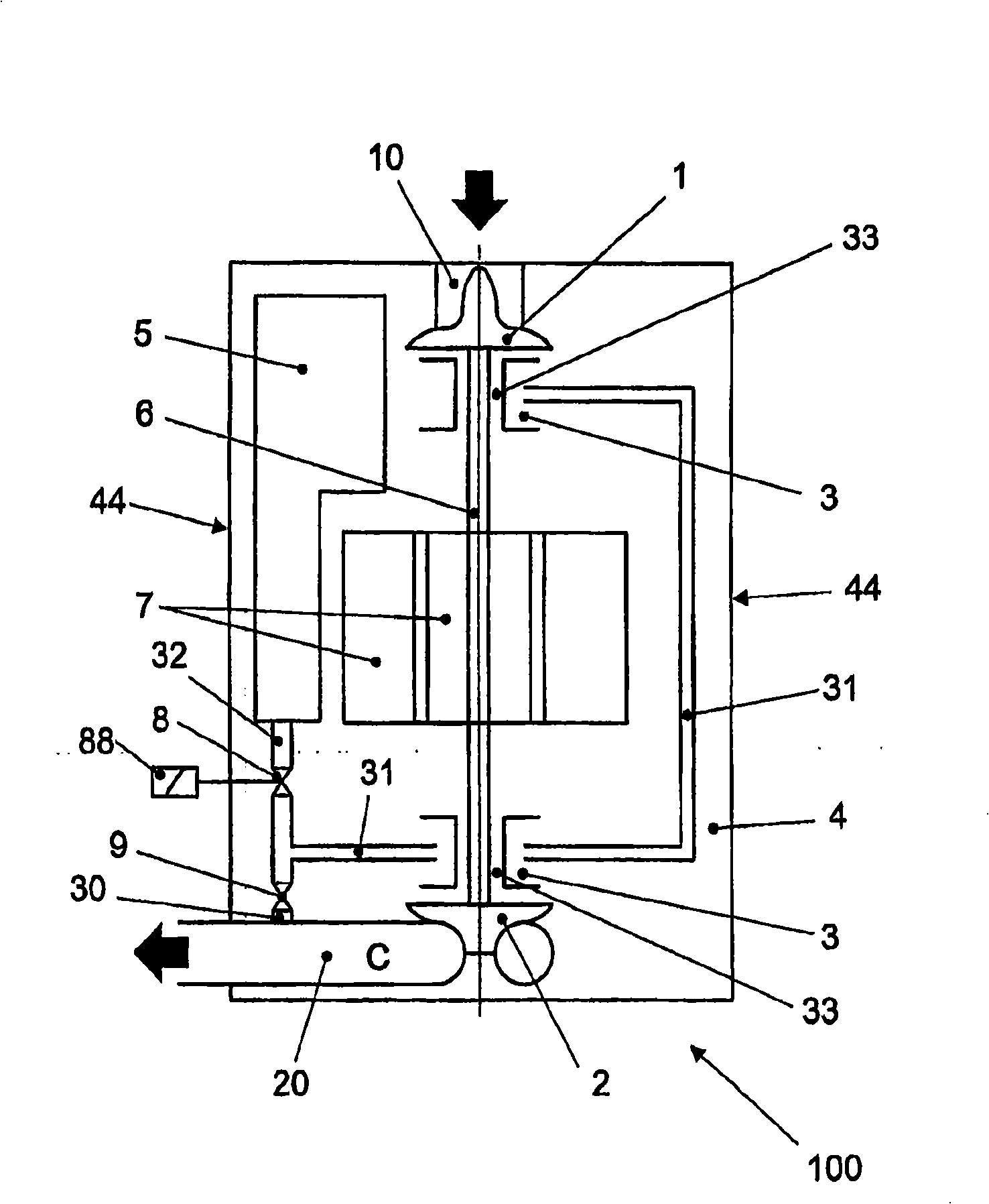

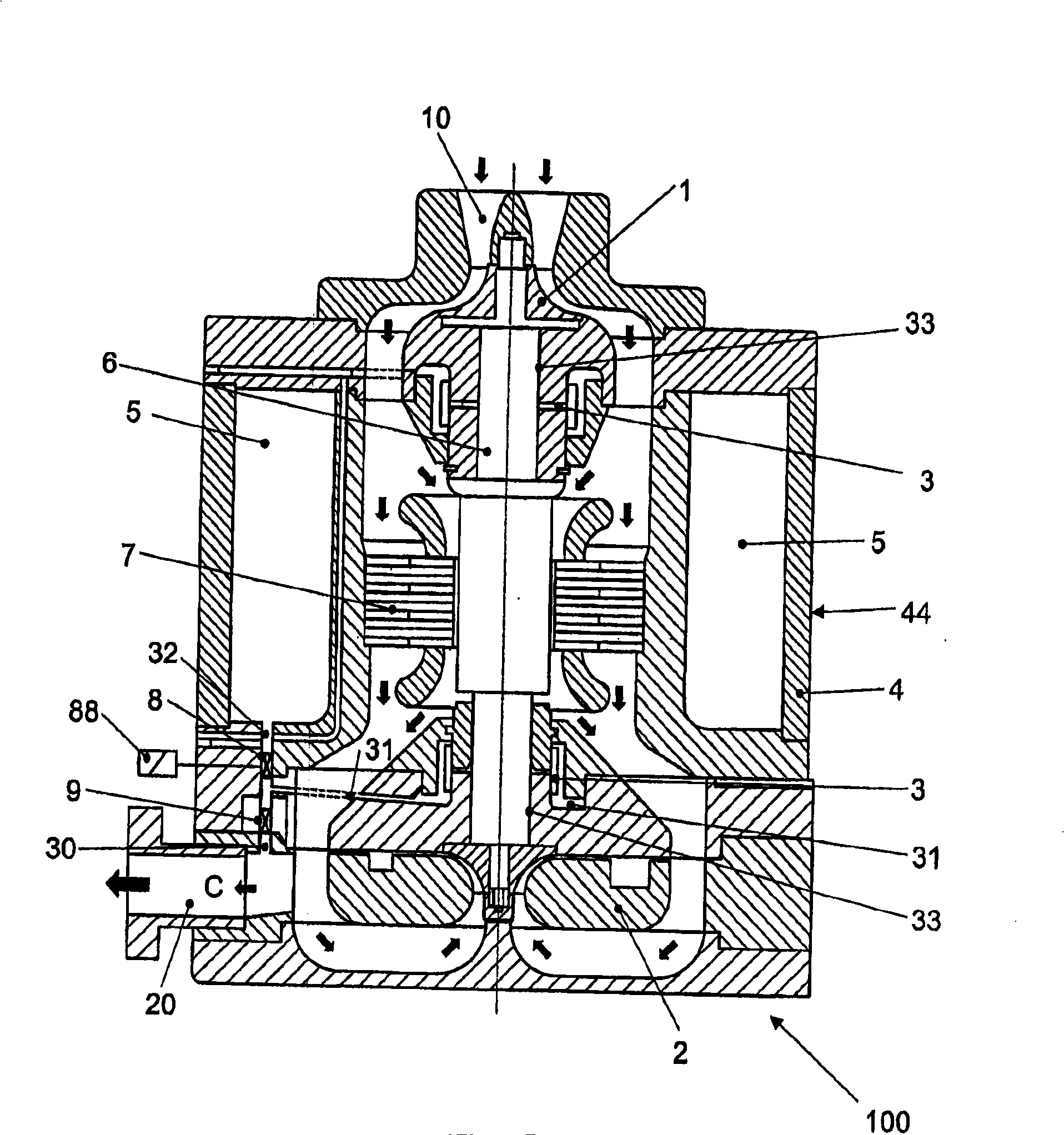

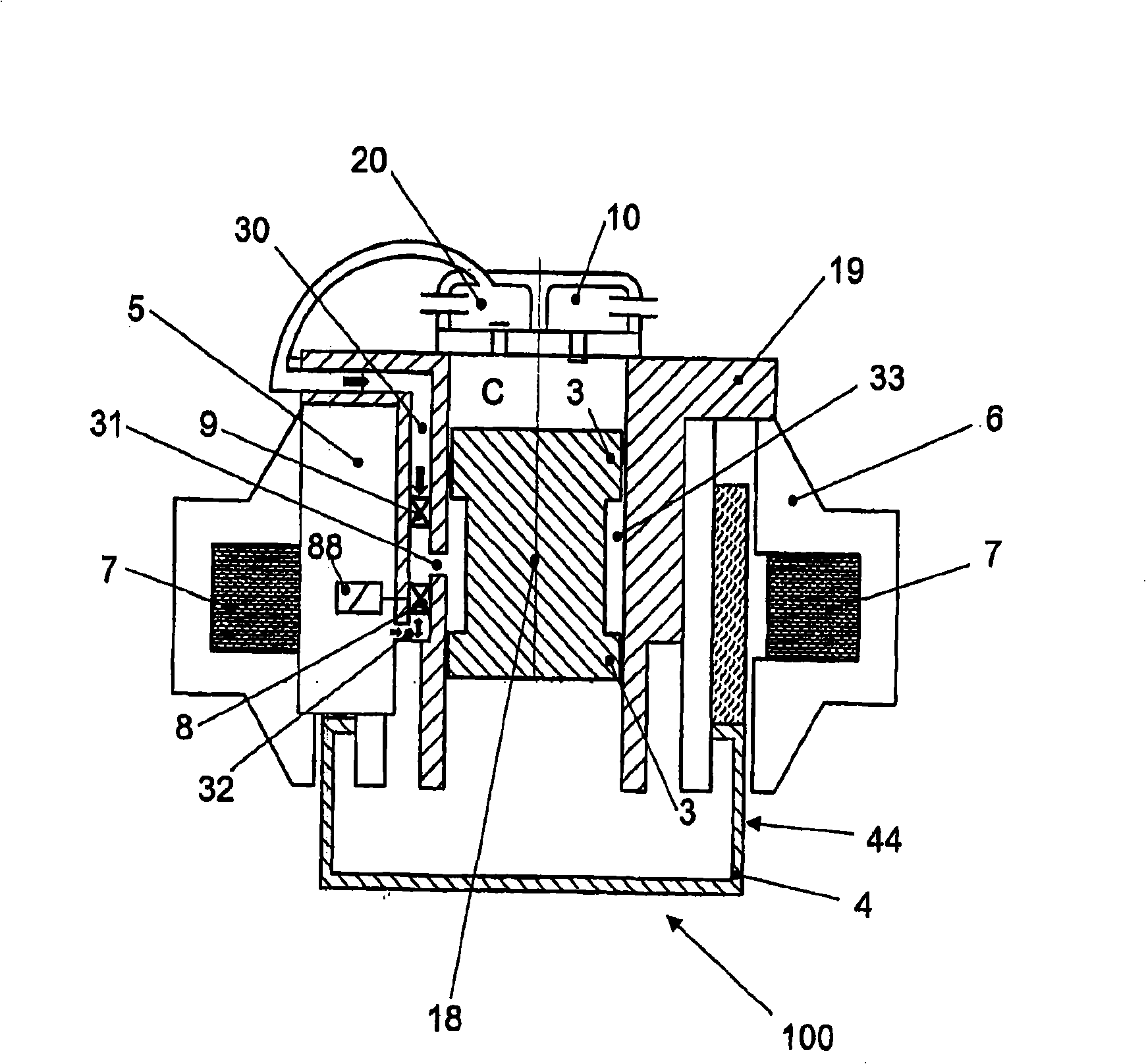

[0022] as from figure 1 and figure 2 As can be seen in , one of the possible embodiments of the teachings of the present invention is their application to centrifugal compressors, for example of the two-stage type. This type of compressor has two stages, the compressor rotor 1 of the first stage of the compressor has the function of drawing fluid (gas) through the non-pressurized inlet 10; The pressure port 20 is used for a cooling circuit (not shown). The two compression rotors 1 , 2 are related, in other words they are fixed mechanically at the end of the same shaft 6 , which in turn is activated by an electric motor 7 . The shaft 6 also has a pair of aerostatic bearings 3 in the floating pressurized region 33, the aerostatic bearings 3 begin to float when subjected to positive pressure.

[0023] In addition, the compressor 100 further comprises a housing 4 comprising an outer or closing wall 44 hermetically enclosing the compressor 100 .

[0024] Another embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com