Sleeve type artificial stirrup bone and production technique thereof

A technology for manufacturing technology and stapes, applied in the field of sleeve-shaped artificial stapes and its manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

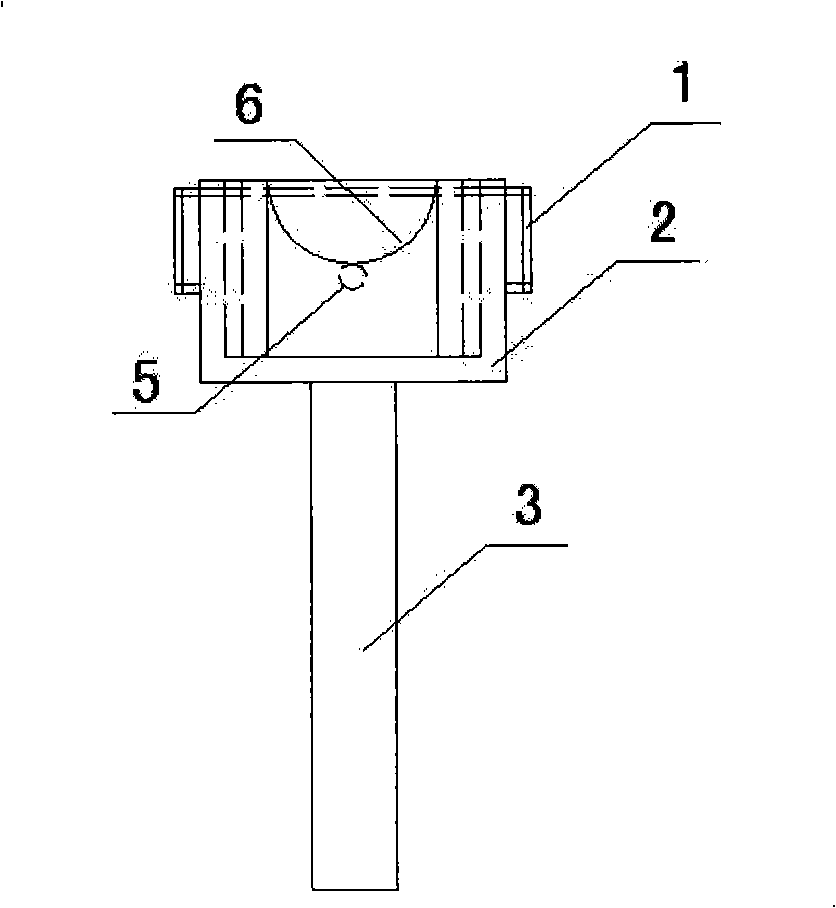

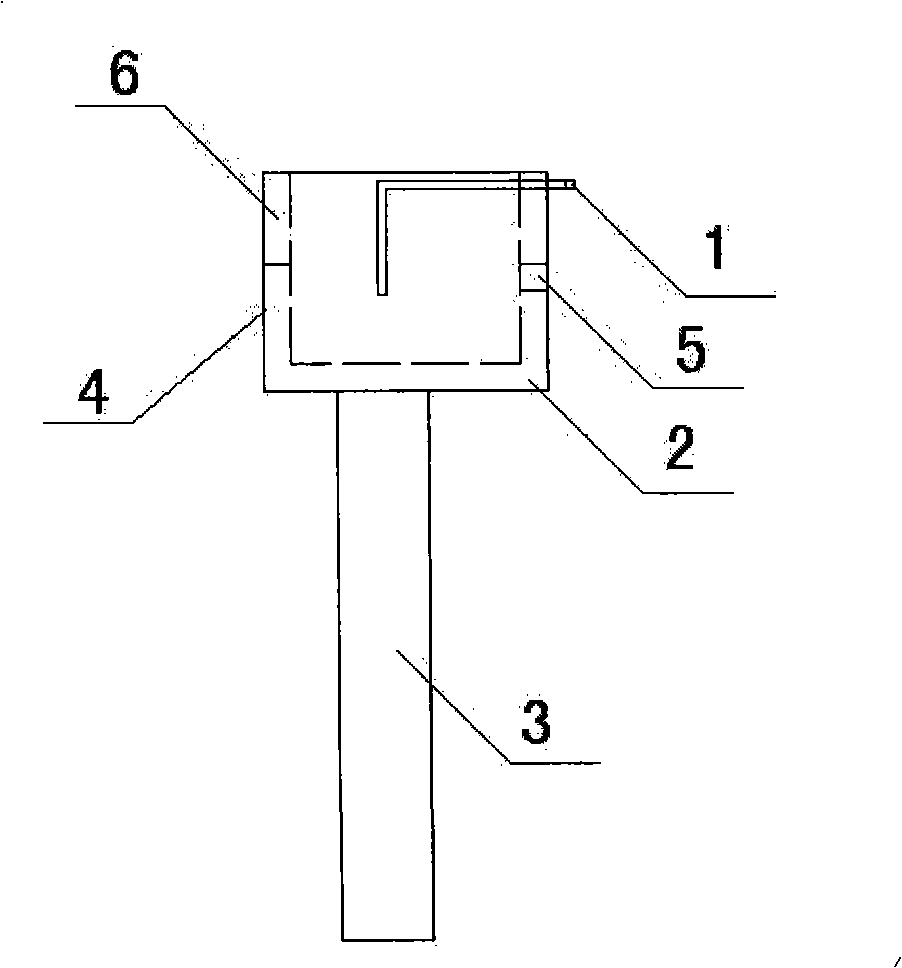

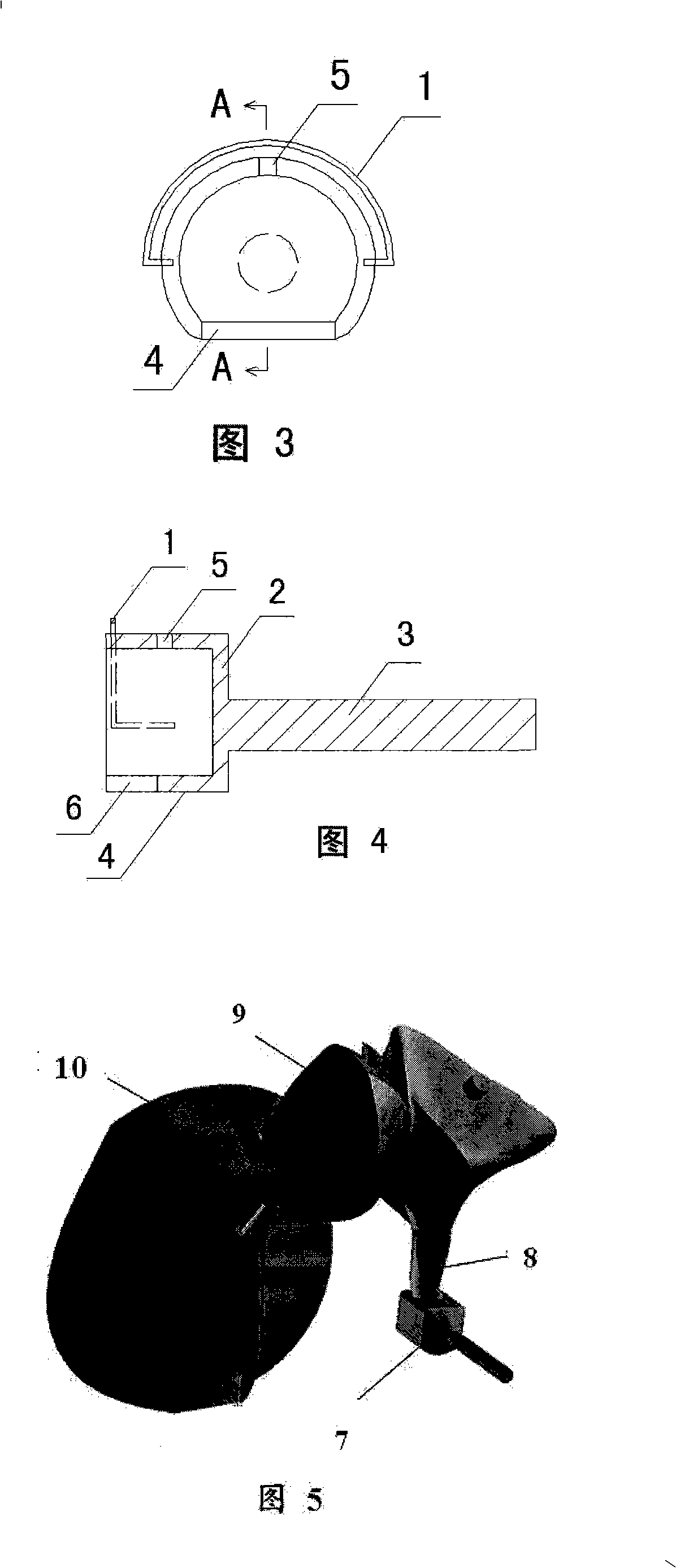

[0025] see figure 1 , figure 2 , Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7 . This set of replacement artificial stapes includes an artificial stapes body 7, the artificial stapes body 7 is a sleeve head 2 configured with the bean-shaped process at the end of the long foot 8 of the incus and a hole on the base plate 11 of the stapes. The mated cylinders 3 are fixedly connected to form a whole. There is a semicircular bracket 6 that is rotationally matched with the long leg 8 of the incus on the sleeve 2 , and the two ends of a metal wire 1 for pressing the long leg 8 of the incus are connected with the sleeve 2 .

[0026] The above-mentioned sleeve head 2 is a cylinder with a semicircular bracket 6, and a side plane 4 parallel to the axis is arranged on the cylinder wall, and a perforation 5 is arranged on the cylindrical wall op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com