Gauze weaving method and gauze waving equipment

A technology of gauze and equipment, applied in the field of gauze weaving, can solve the problems of poor strength, high cost, poor quality of gauze fabrics, etc., and achieve the effects of reducing production cost, improving strength and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

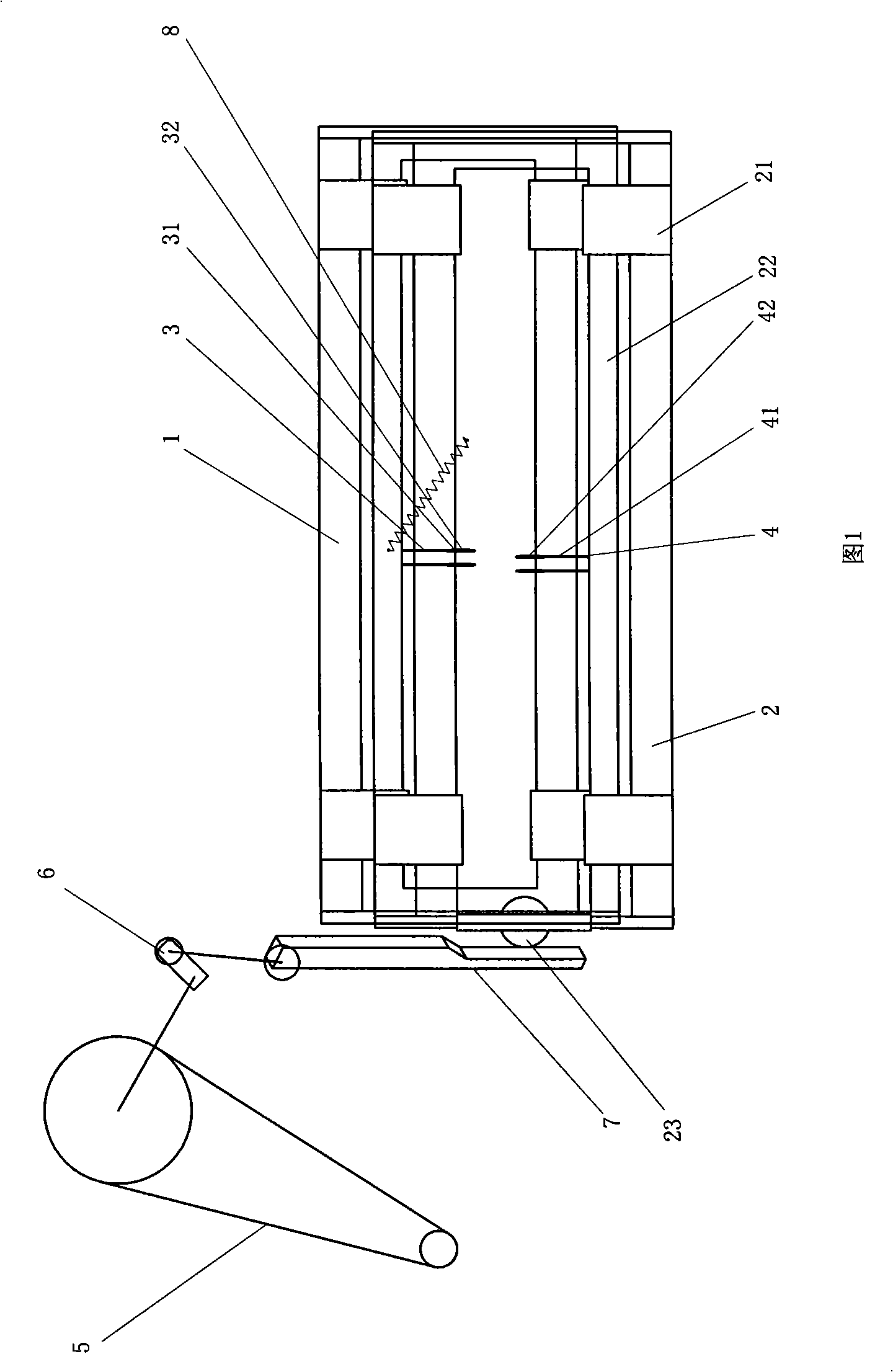

[0023] The gauze weaving method in this group of inventions will be described with emphasis below in conjunction with the gauze weaving equipment in the present invention. The above gauze weaving equipment, its shedding mechanism, weft insertion mechanism, warp let-off mechanism, coiling mechanism and other auxiliary mechanisms Other parts, except the following technical content, can adopt or refer to relevant parts in the water-jet weaving and water-jet loom technology in the prior art for reference. The most relevant prior art features are combined below, and the technical features that the invention contributes to the prior art are highlighted:

[0024] A gauze weaving method can be carried out successively in a cycle according to the following steps:

[0025] ①The warp yarn forms a shed;

[0026] ②Use the water jet as the carrier to carry the weft yarn into the shed and beat up the weft;

[0027] ③In the warp yarns, each corresponding two warp yarns are twisted once.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com