Special soft foundation consolidation method

A kind of foundation, extra-soft technology, applied in basic structure engineering, soil protection, construction and other directions, can solve the problems of unsafe mechanical walking, high cost, poor safety, etc., and achieve the effect of shortening construction period and easy and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

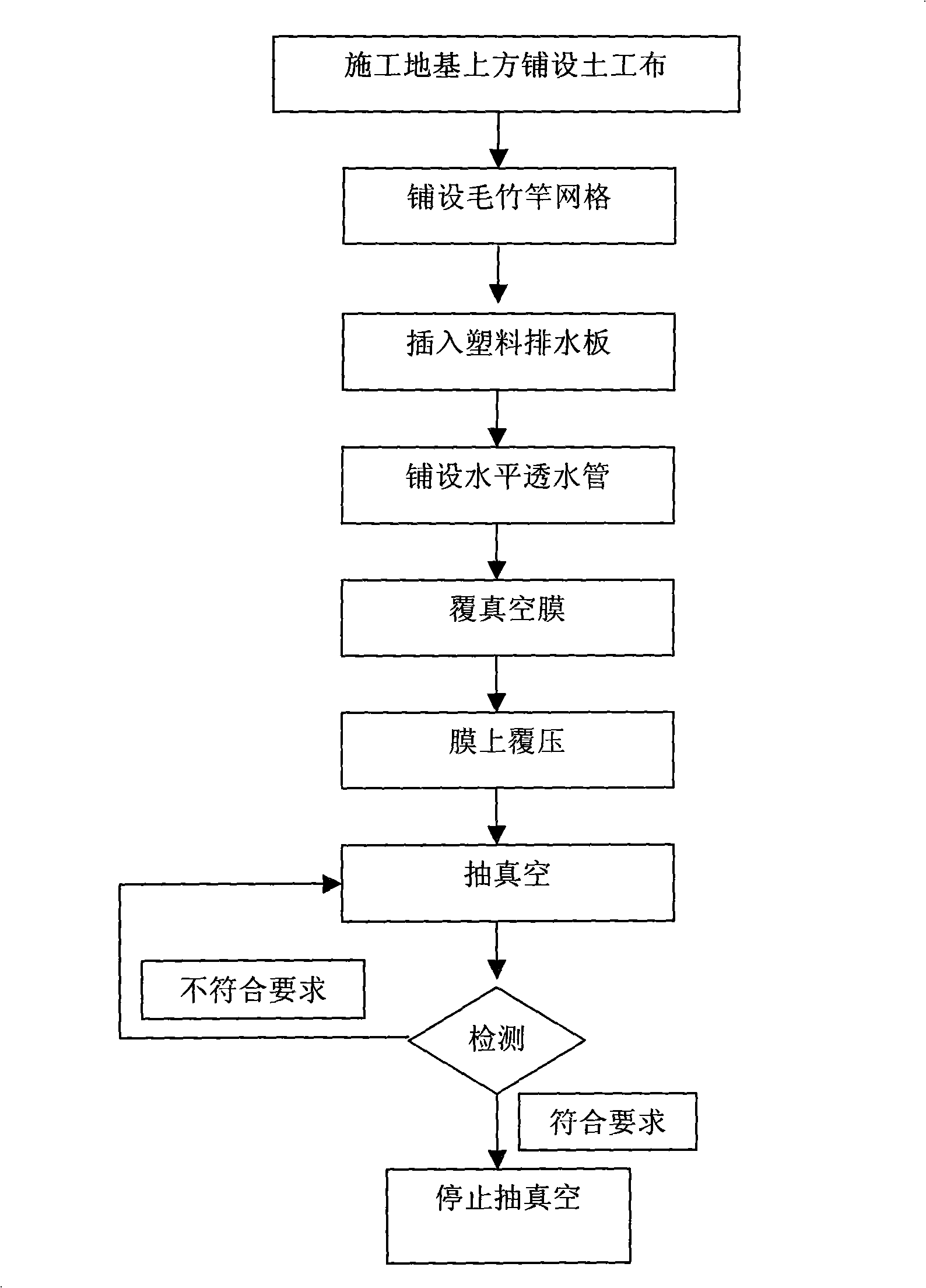

Method used

Image

Examples

Embodiment 1

[0060] Example 1 , Consolidation of extra soft ground in a certain project

[0061] The project is located in a development zone in Linhai. A large area of dredging and filling of silt has been carried out in this project, and foundation consolidation is required. After treatment, f ak >80kpa, the post-construction settlement is less than 50cm.

[0062] The geological data of the construction site are: dredged muddy soil with an average thickness of 4.5 meters, a water content of 90%, and a bearing capacity of 12kPa. The original soil layer is muddy silt, with an average thickness of 10 meters and a water content of w=45%, f ak ≈40kpa; the underlying layer is silty clay, f ak = 80kPa.

[0063] The specific implementation plan is as follows:

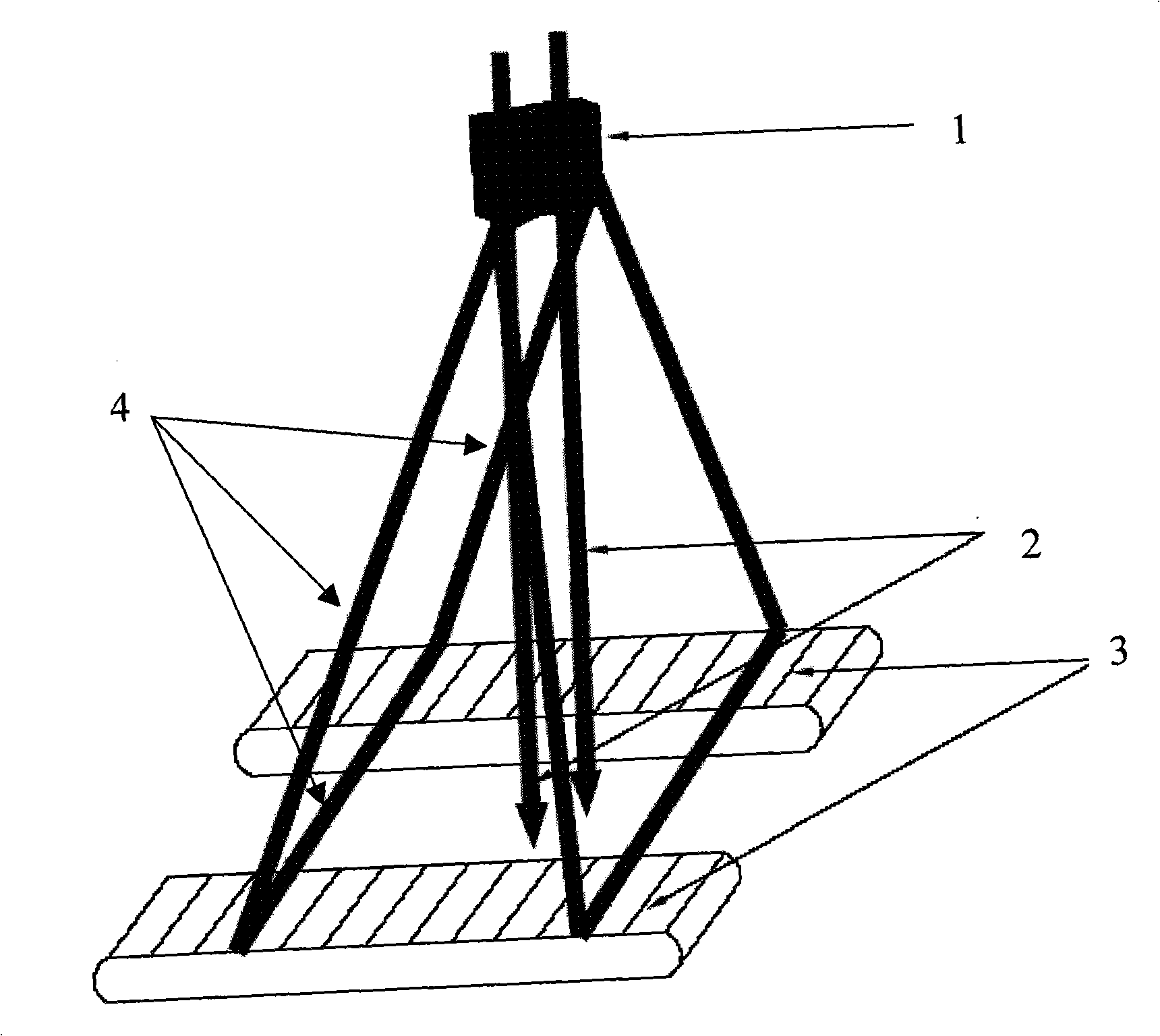

[0064] A self-made portable crawler-type inserting machine was selected for construction. The specific construction parameters are determined by the following methods:

[0065] 1. f ap determination of

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com