Vacuum apparatus for conductor jostling sheath machine

A technology of vacuum device and sheathing machine, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of wire 5 fluctuations, defective products, and affecting the vacuuming stability of vacuum pump 3, so as to avoid fluctuations and ensure The effect of stationarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

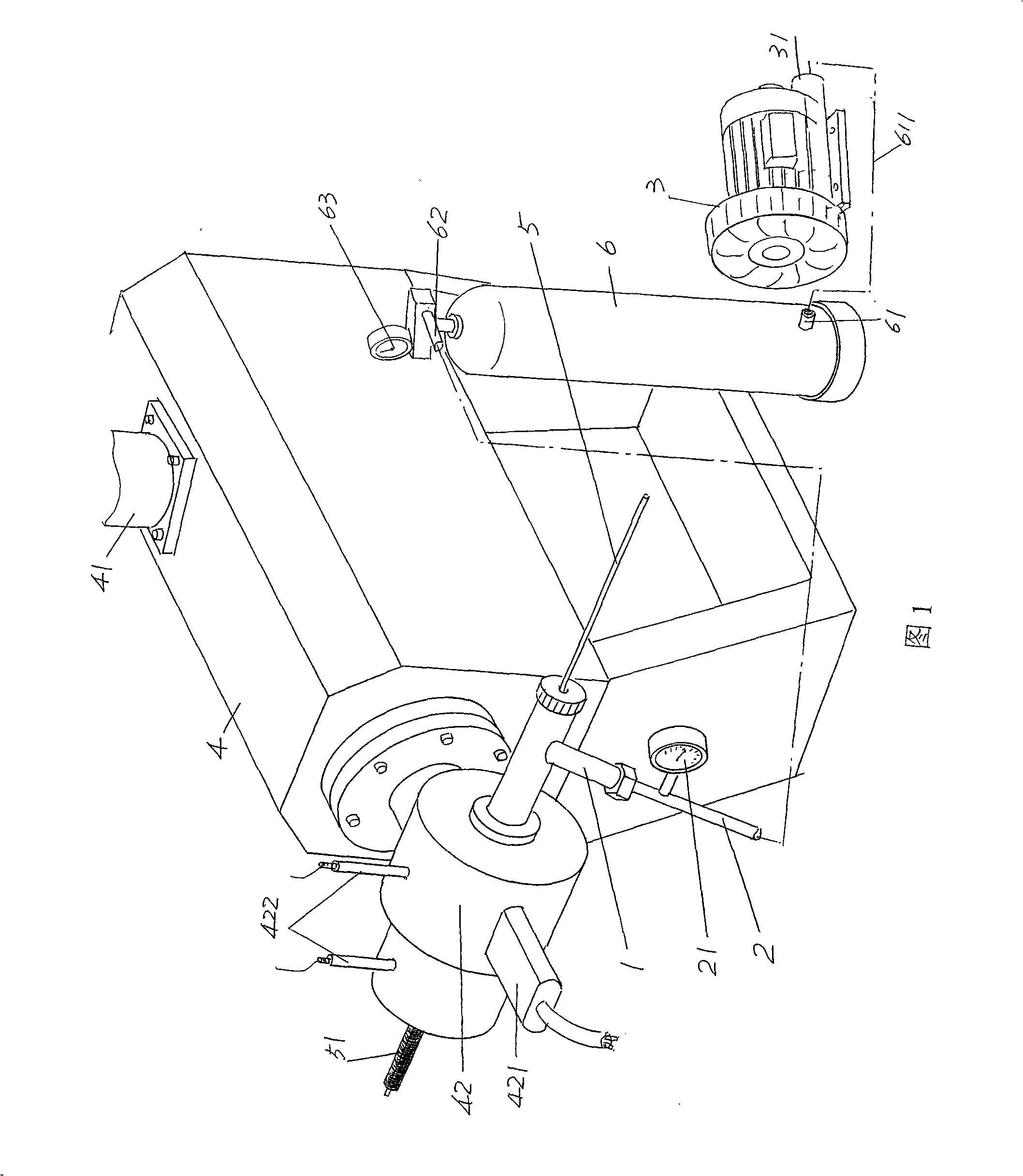

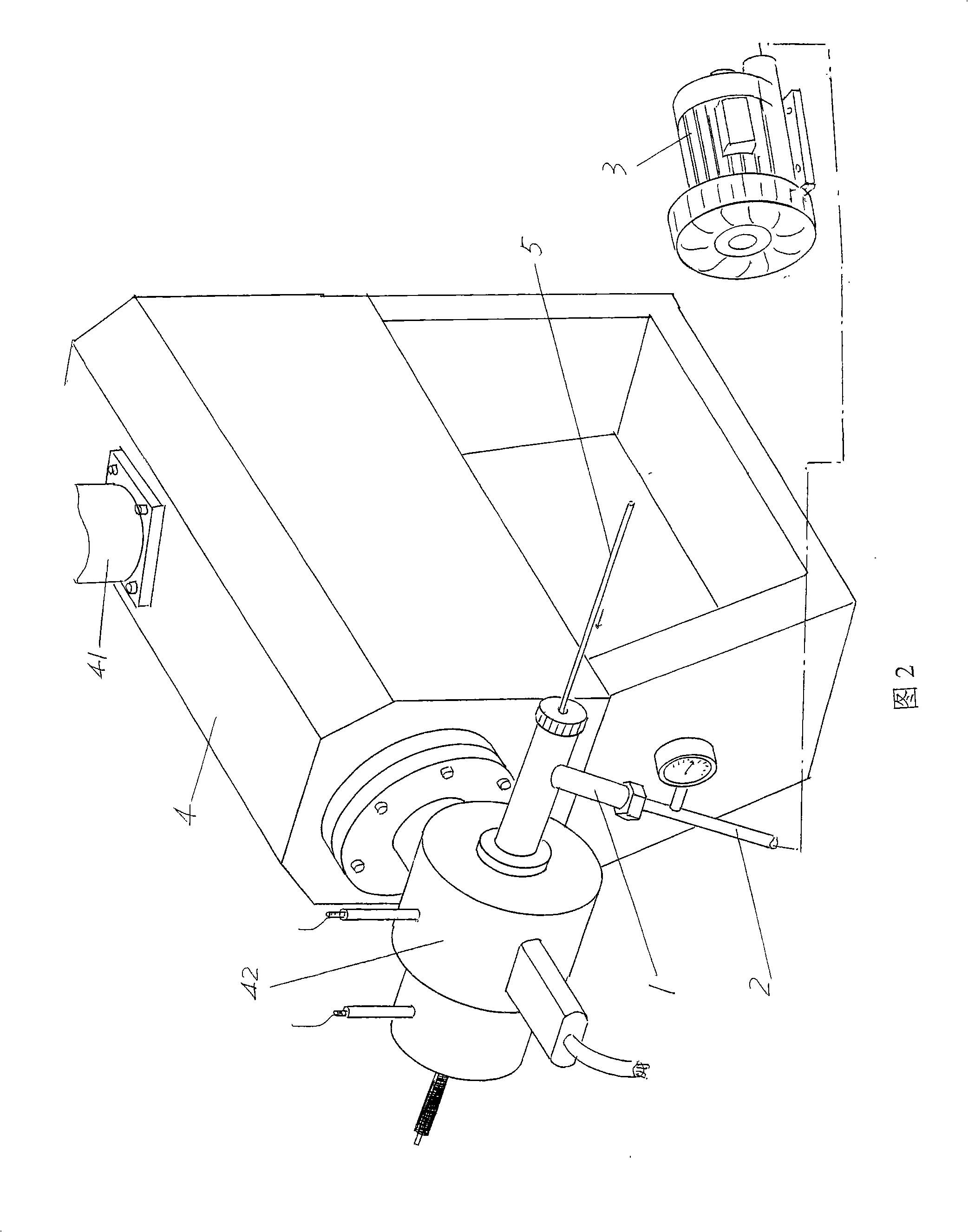

[0009] Please see Fig. 1, the top of the wire extrusion sheathing machine 4 is a hopper 41 for introducing plastic particles, the head of the wire extrusion sheathing machine 4 is an extrusion sheathing head 42, and a power interface 421 and a thermocouple 422 are arranged on it After the wire 5 is introduced into the extruded sheath head 42, the outer extruded sheath 51 of the wire 5 by the extruded sheath head 42 constitutes a sheath line. On the extruding sheath head 42 of the wire extruding sheathing machine 4, the vacuum interface 1 of the vacuum device of the wire extruding sheathing machine provided by the present invention is connected, and one end of the vacuum pipeline 2 is connected on the vacuum interface 1, and the vacuum pipeline The other end of 2 is connected with the air inlet 62 of the air storage tank 6, and the gas outlet 61 of the air storage tank 6 is connected with the suction port 31 of the vacuum pump 3 through the pipeline 611. The top of the air stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com