Light-cured quick forming device and method based on reflection-type liquid crystal light valve

A liquid crystal light valve and molding device technology, which is applied to optical components, other household appliances, household appliances, etc., can solve problems such as low resolution, and achieve the effects of improving resolution, high precision, and high molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

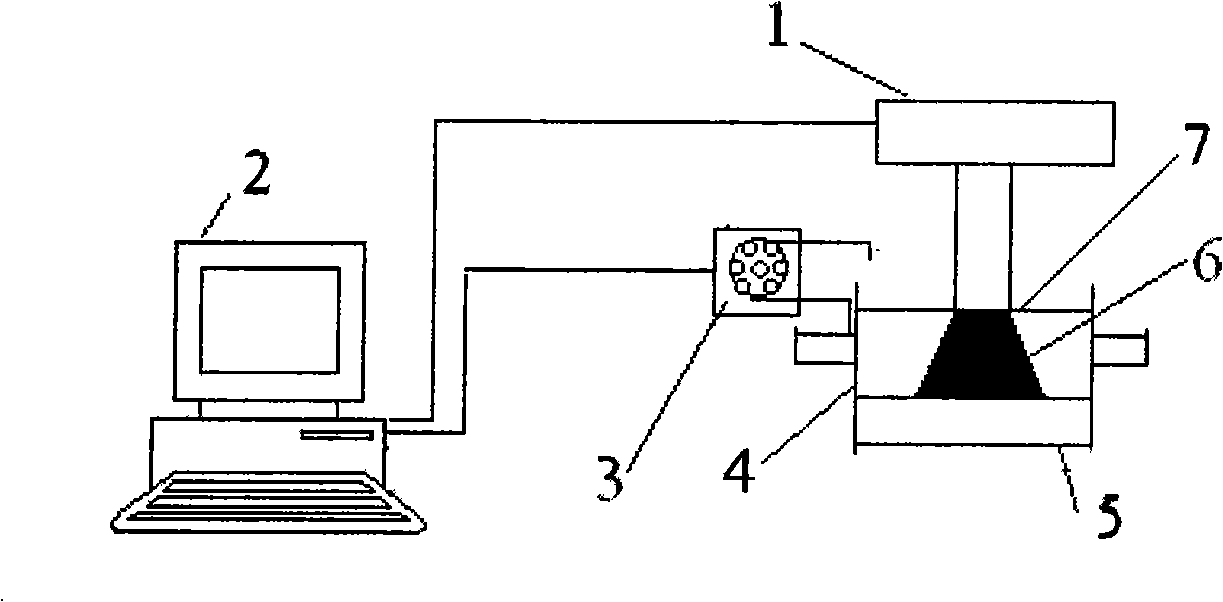

[0027] The structure of molding device of the present invention, as figure 1 shown. Including a computer 2, the computer 2 is respectively connected with the pattern generator 1 and the peristaltic pump 3, the peristaltic pump 3 communicates with the resin tank 4, and the resin tank 4 is provided with a lifting table 5, and the pattern generator 1 is located above the lifting table 5, Between the pattern generator 1 and the upper surface of the lift table 5, a layer of liquid photosensitive resin layer 7 is input into the resin tank 4 by a peristaltic pump 3 .

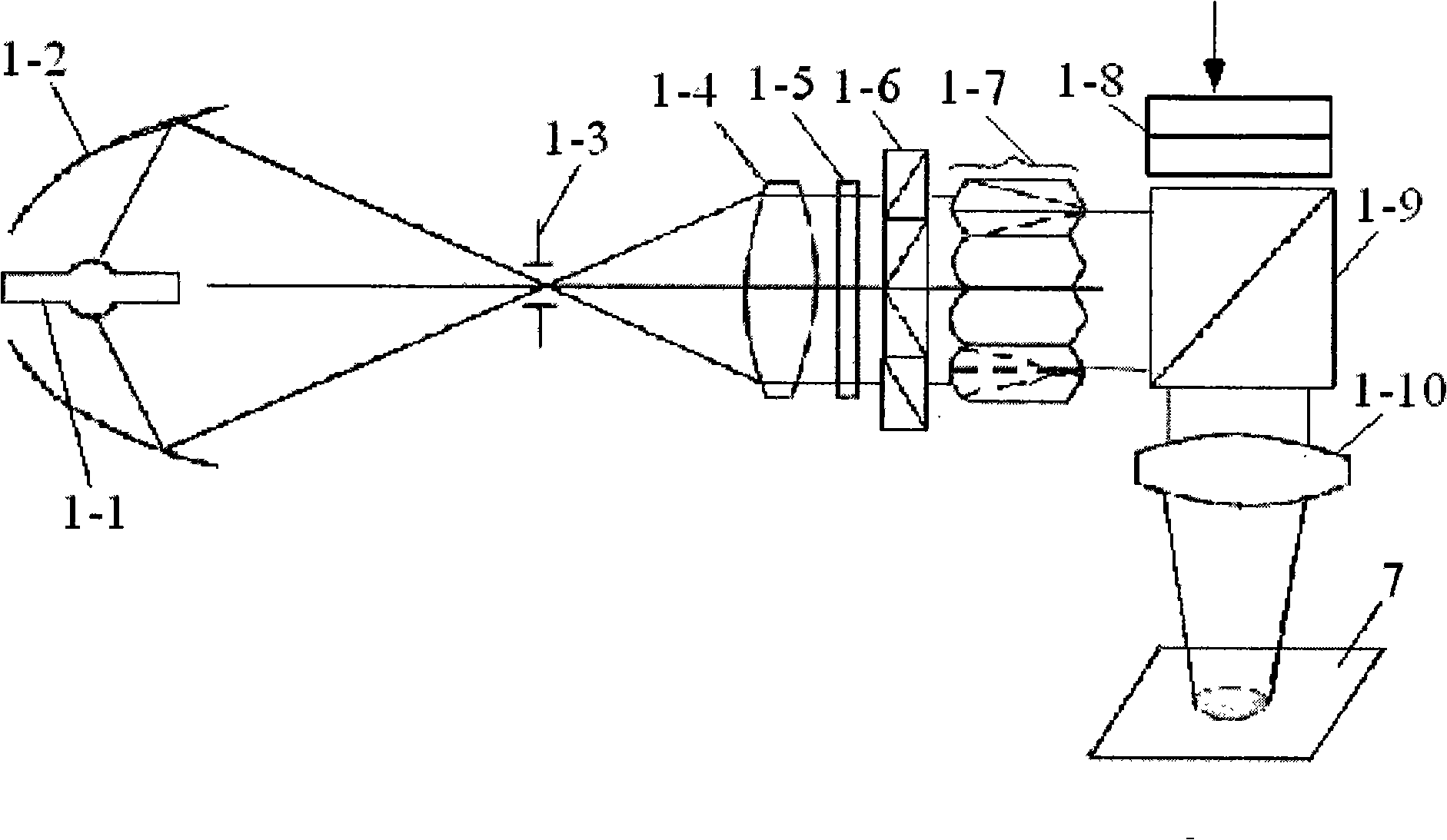

[0028] The structure of pattern generator 1 in the device of the present invention, as figure 2 shown. Along the same axis, a light source 1-1, a diaphragm 1-3, a collimating lens 1-4, a filter 1-5, a polarization conversion system PCS 1-6, a homogenizer 1-7 and a polarization bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com