Adjustable blade pitch device eccentric lining structure and assembly method

A technology of eccentric bushing and eccentric distance, which is applied in the control of wind turbines, engines, mechanical equipment, etc., can solve problems such as difficult to meet the standard requirements, and the pitch adjustment frame is stuck, so as to reduce manufacturing difficulty, save manufacturing costs, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

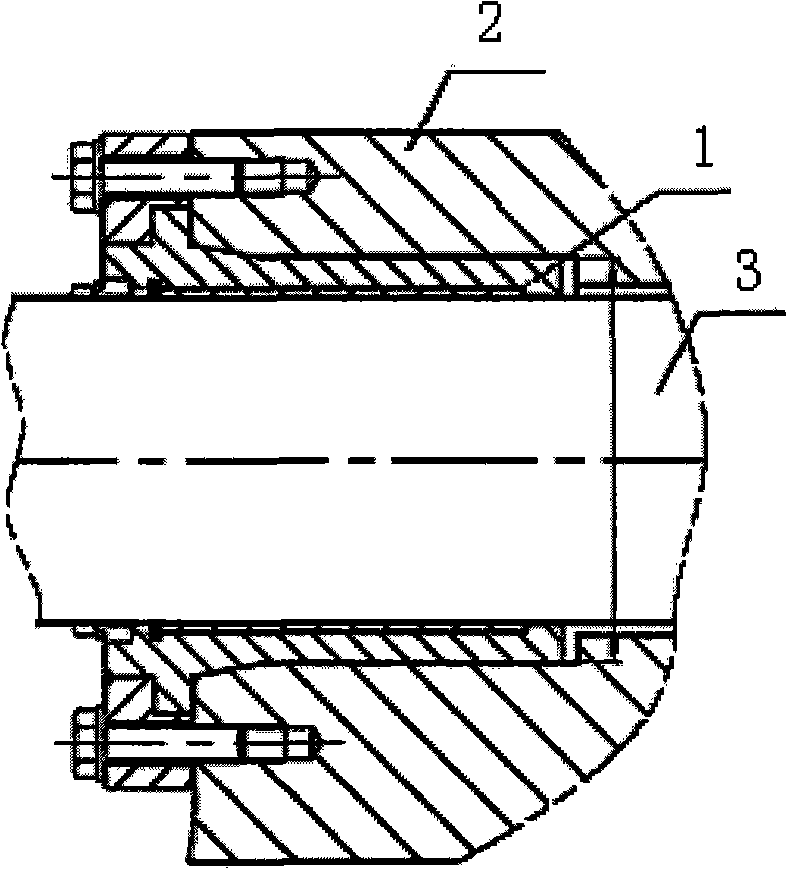

[0017] The present invention designs an eccentric bushing in the guide hole of the pitch adjusting frame that can adjust coaxiality, parallelism, and position. During the assembly process of the pitch adjusting frame, the 3 The coaxiality, parallelism, and positional errors between the first guide rod and the guide hole of the pitch adjustment frame, so as to avoid the jamming phenomenon of the pitch adjustment frame when moving along the guide rod.

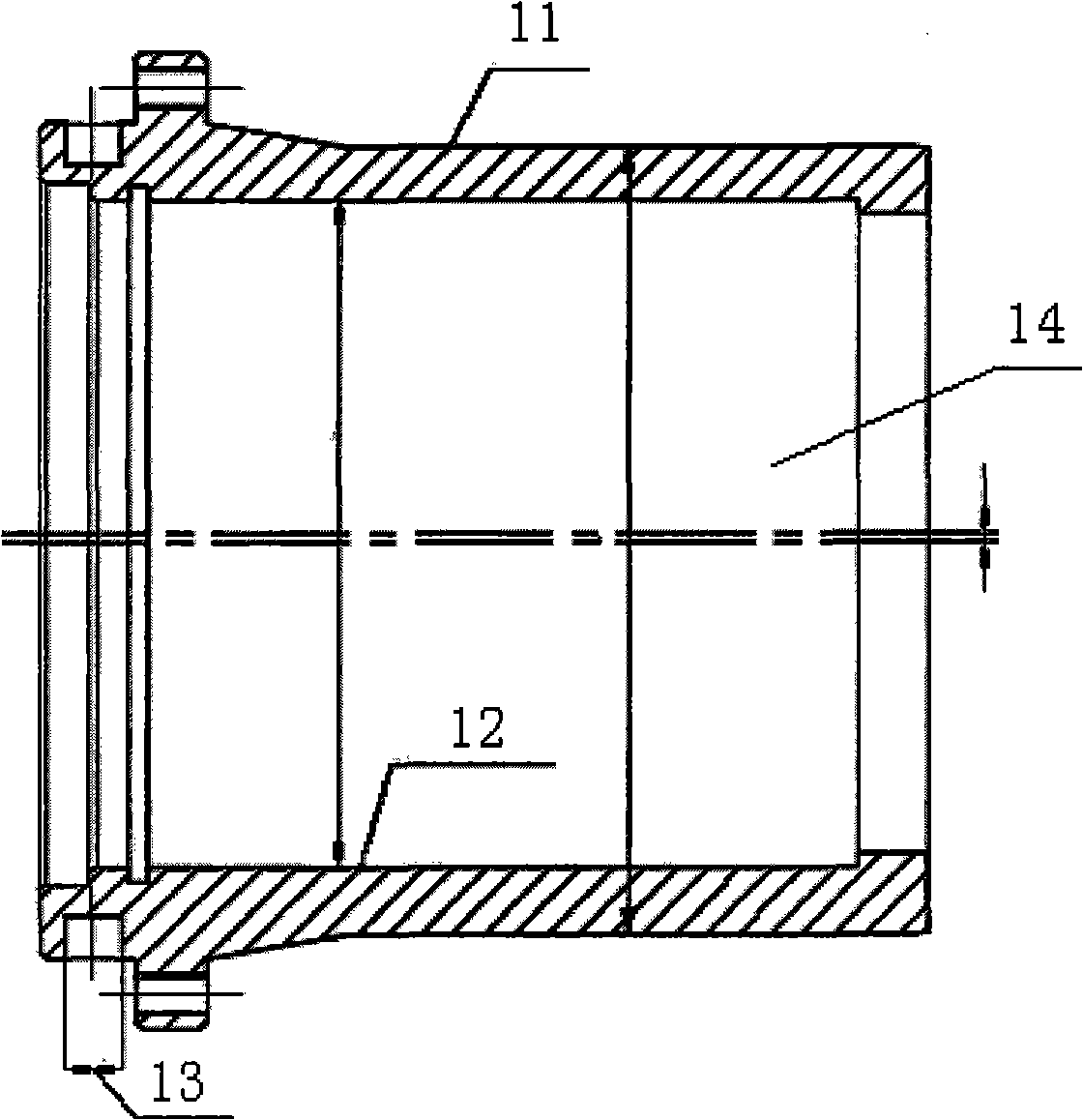

[0018] refer to figure 1 , figure 2 : An eccentric bushing 1 of an adjustable pitch mechanism, the pitch mechanism includes a pitch adjusting frame 2 with a guide hole and a guide rod 3, wherein the eccentric bushing 1 is installed in the guiding hole of the pitch adjusting frame 2, And the guide rod 3 is installed in the eccentric bush inner hole 14, the diameter of the outer ring 11 of the eccentric bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com