Gas discharge tube automatized ageing device

A technology of gas discharge tube aging refining, which is applied in the direction of discharge tube testing and sorting, can solve the problems of large dispersion, bulky equipment, large dispersion of gas discharge tube breakdown voltage, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

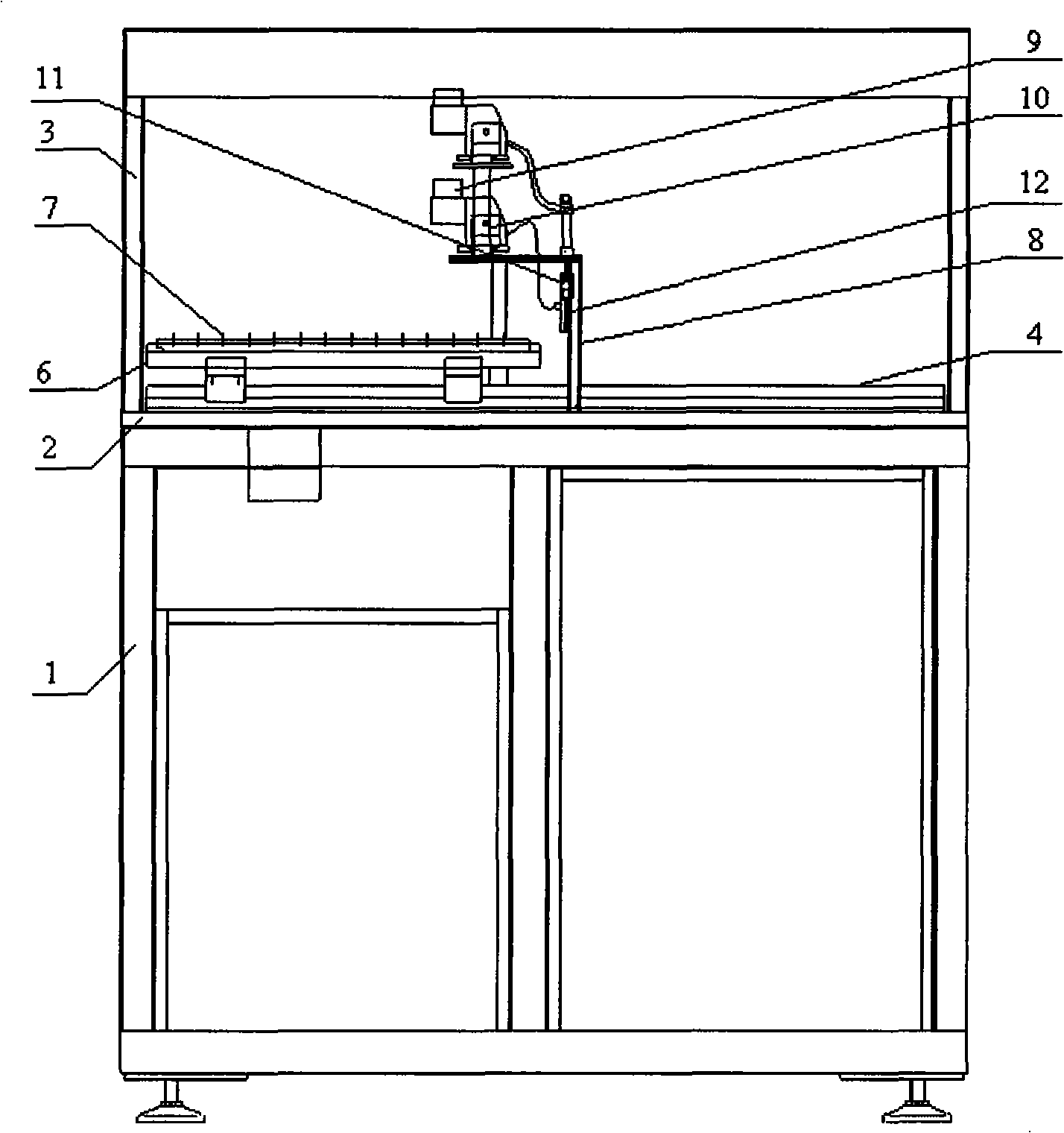

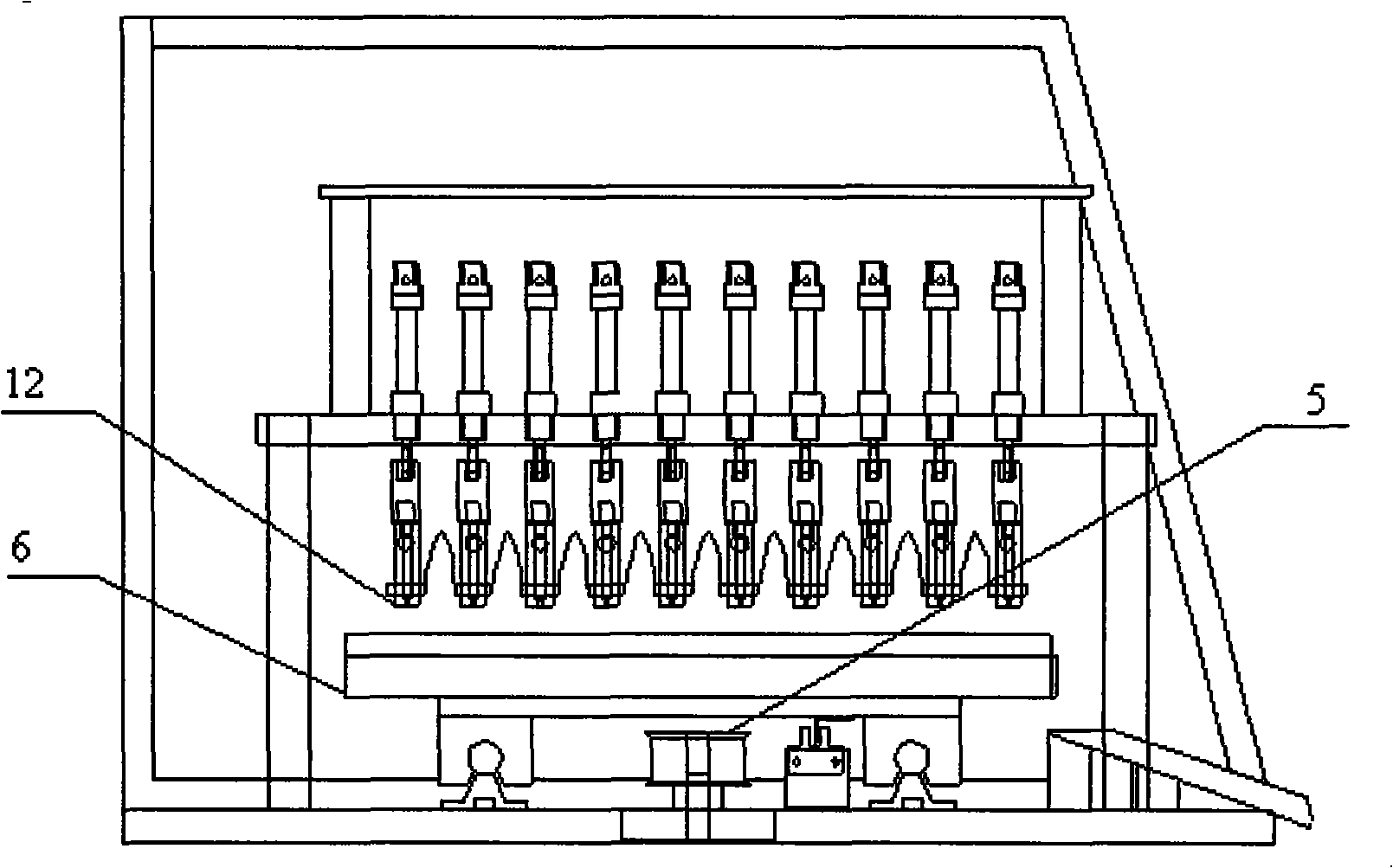

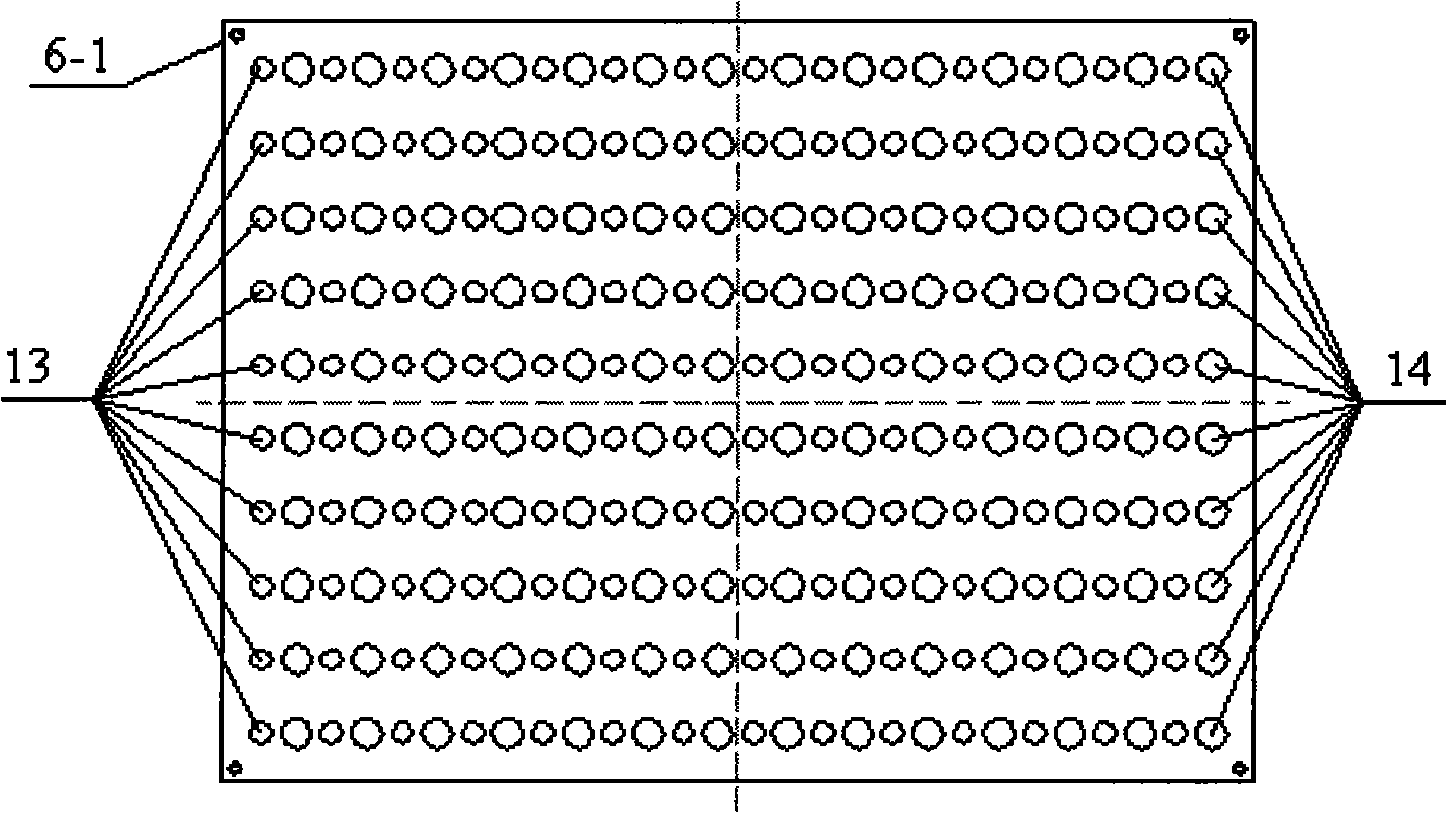

[0018] see Figure 1a , 1b, the present invention comprises a console frame 1 and a platform 2 and a gantry frame 3 arranged on the console frame 1, a track 4 is installed on the platform 2, and a synchronous wheel connected with a motor is installed on the track 4 5. The test board 6 is fixedly installed on the synchronous wheel 5. The gas discharge tube 7 is placed on the test plate 6. The synchronous wheel 5 is driven by the synchronous electrode. The gantry frame 3 is provided with a cylinder 11 connected to the mature power supply of the gas discharge tube The electrode 12 is fixedly mounted on the cylinder 11 , and an insulating support rod 8 is provided on the platform 2 , the mounting plate 9 is fixed on the insulating support rod 8 , and the solenoid valve 10 for controlling the cylinder 11 is disposed on the mounting plate 9 .

[0019] Referring to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com