Ship rotation speed control system risks prealarming method

A technology for speed control and risk early warning, applied in electrical testing/monitoring, etc., can solve problems such as intricate relationships, and achieve the effect of ensuring safety, improving scientificity, and improving routine maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

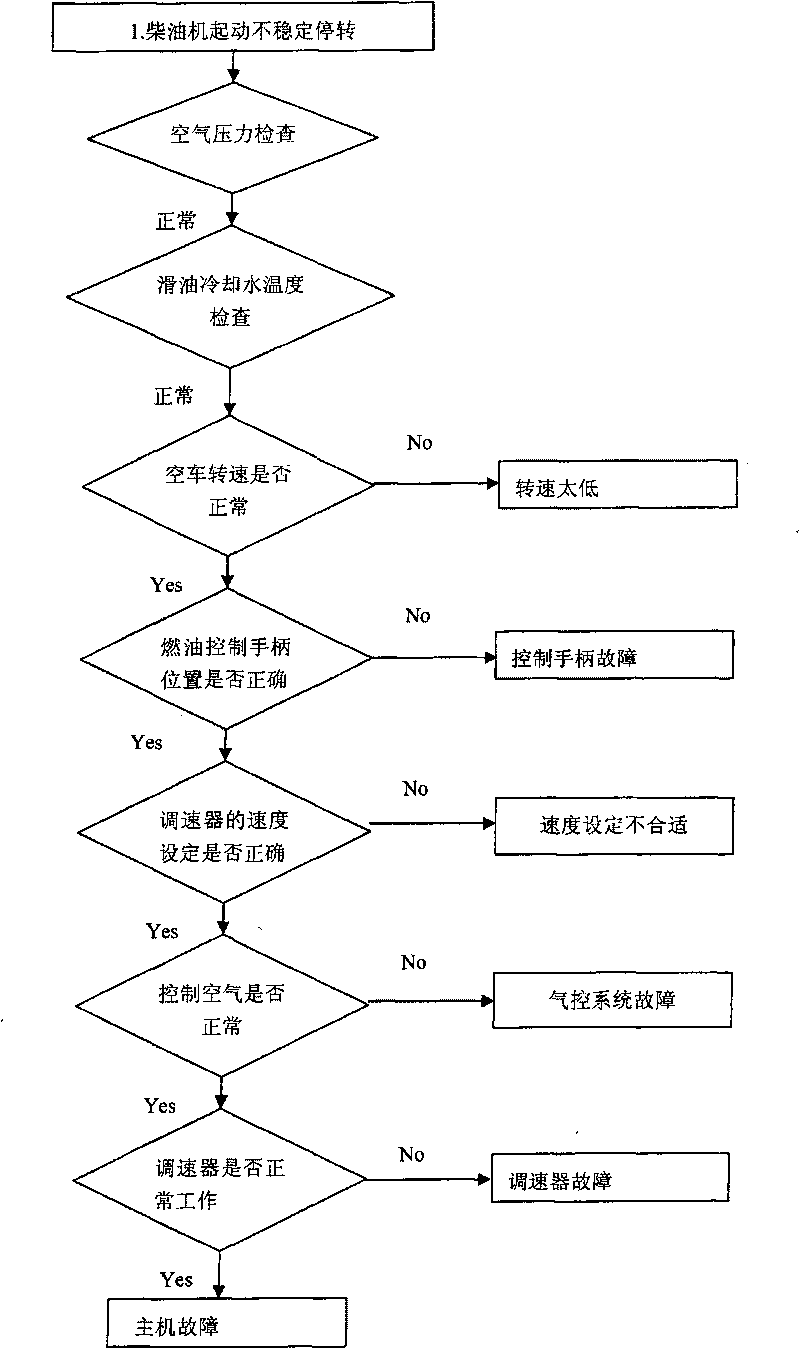

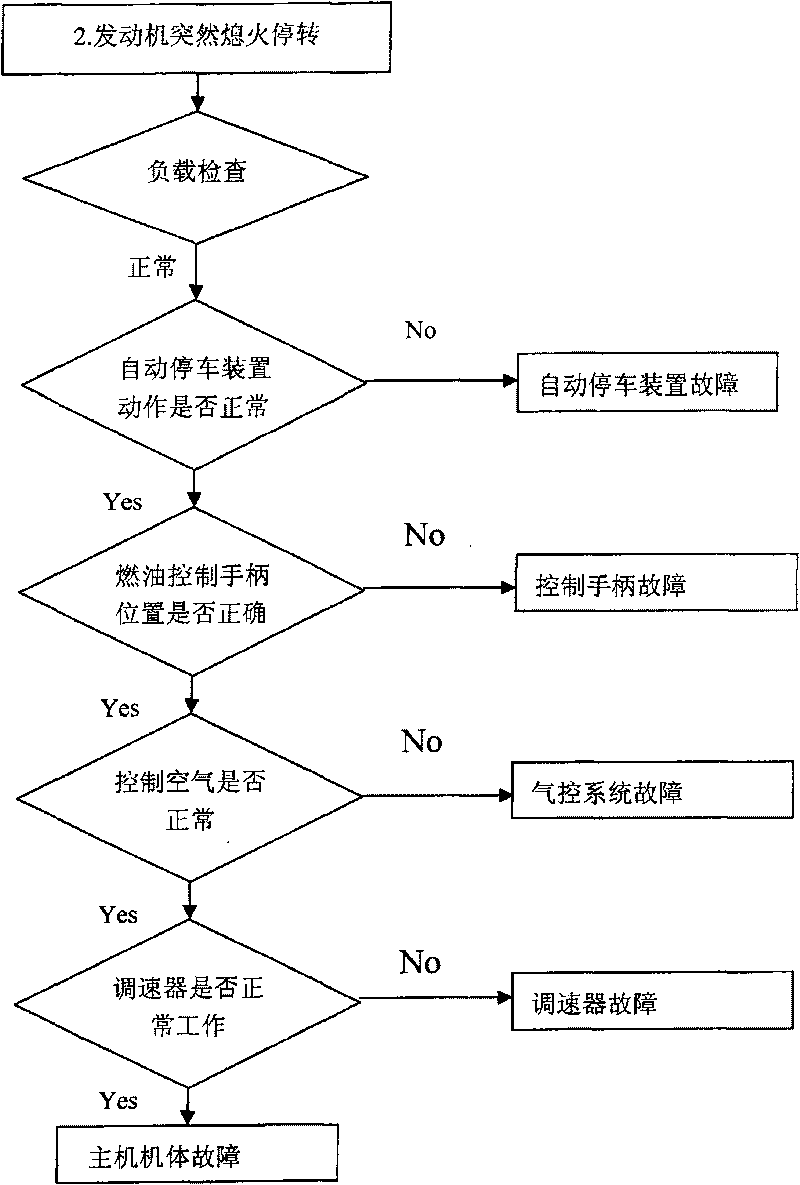

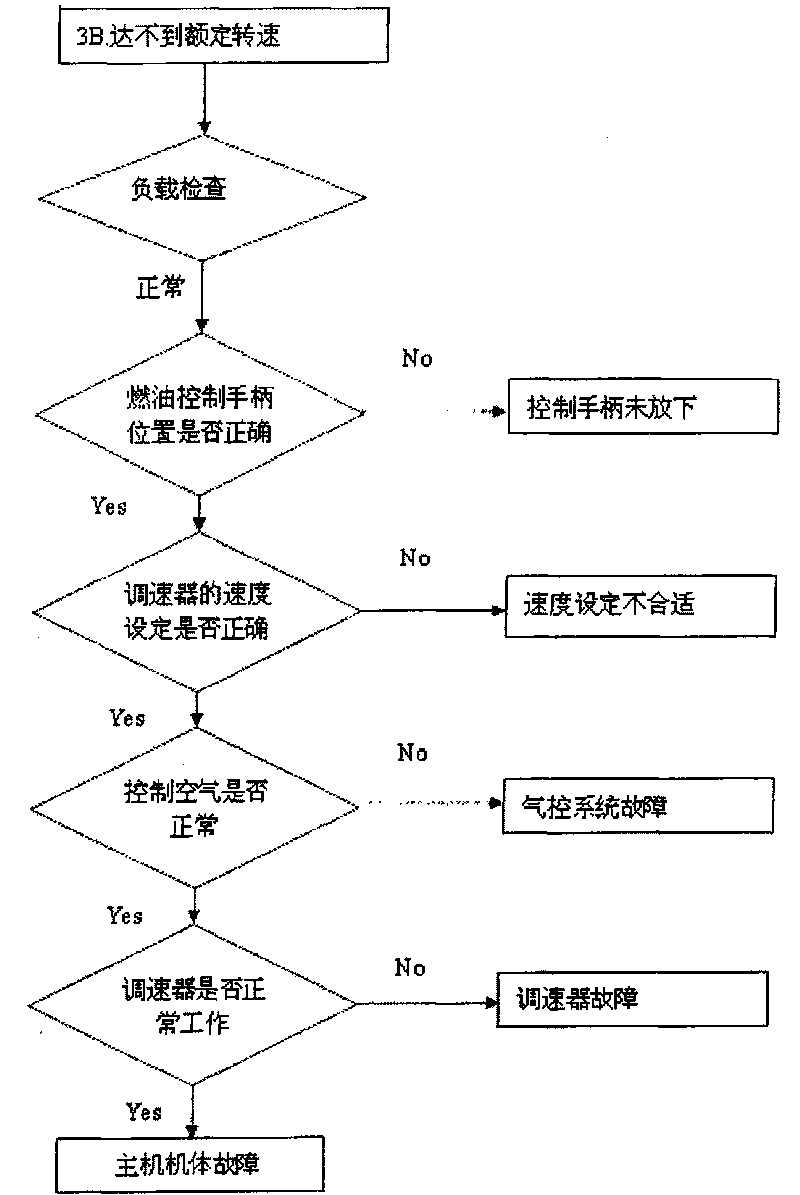

[0046] The working principle of the speed control system is firstly described as follows:

[0047] Engine speed is controlled by a Woodwater PSG governor mounted on the control side, which controls the position of the fuel injection pump rack through the fuel control lever. The fuel injection pump is installed upside down in the body under the camshaft. The fuel pump rack is connected to the fuel control lever installed in the body through a clamping block and a short tension spring, and the control lever is loaded in a pair of rollers for axial movement. The movement of the fuel control lever is transmitted to the gear body of the fuel pump through the clamping block that is forced to lock in the direction of full load, and the direction of "parking" depends on the action of the tension spring. This structure allows one or more fuel injection pumps to be stuck At this time, the oil pump rack can be pulled in the direction of "parking", so that the engine can be parked under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com