Novel sludge storage tank

A mud storage tank and a new type of technology, applied in the field of mud storage tanks, can solve the problems of not being able to work continuously for a long time, affecting the operation of sludge dewatering, and small application range of mud storage tanks, so as to improve the management of sludge dewatering and outbound transportation. , Avoid night transportation, less daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

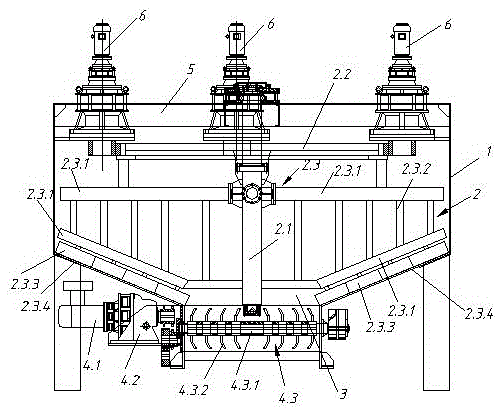

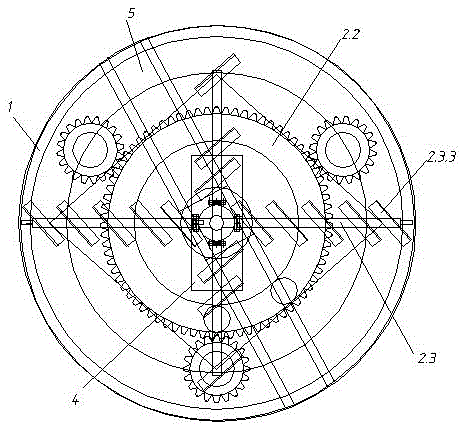

[0010] Embodiment 1: a kind of novel mud storage tank, comprises circular tank body 1, plate type mud pusher 2, mud storage hopper 3, mud storage hopper blanking turning device 4 etc., tank body 1 top has horizontal frame 5, tank body 1 is provided with a plate-type mud pusher 2, which includes a main shaft 2.1 located in the center of the tank body 1, a large transmission gear 2.2 fixedly connected to the main shaft 2.1, and four sets of push arms 2.3. The push arms 2.3 include two angled There are 5 vertical support columns 2.3.2 fixed between the push rod 2.3.1 and the push rod 2.3.1 at 30-60 degrees, and the end of the push rod 2.3.1 is provided with a connecting flange, which is connected to the side wall of the main shaft 2.1 The flange corresponding to the upper part is fixed, and the bottom end of the push rod 2.3.1 is welded with three parallel mud pushing plates 2.3.3. The mud pushing plate 2.3.2 is turned around the longitudinal axis by 25~120 degrees. .3 The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com