Connection apparatus of universal serial bus, connecting module group and manufacturing method thereof

A universal serial bus and connection device technology, which is applied to two-part connection devices, parts of connection devices, connections of four or more poles, etc., can solve problems such as poor contact, fatigue, aging elasticity of shrapnel, etc., to achieve Avoid poor contact and small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

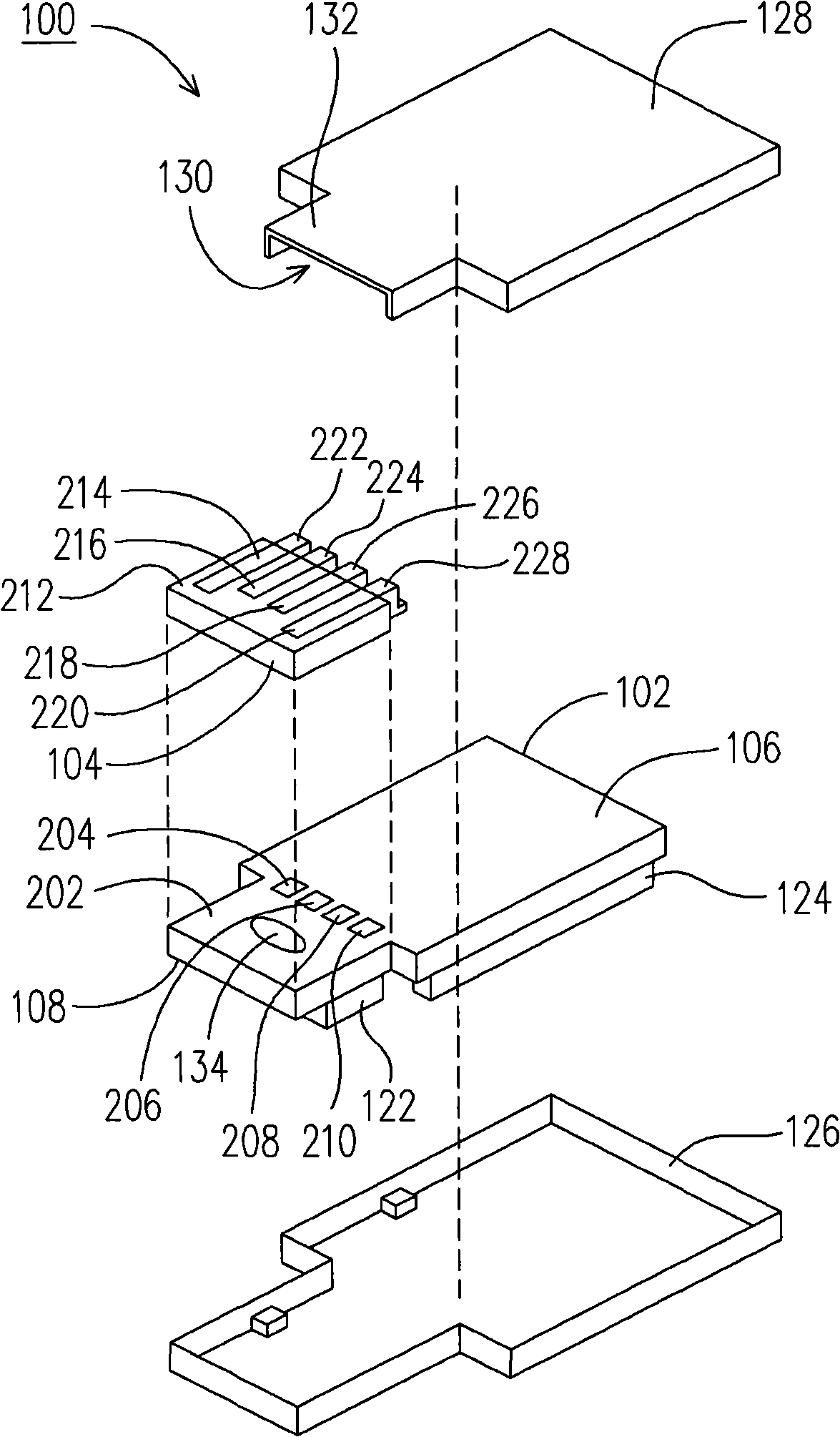

[0025] figure 1 It is a three-dimensional structure diagram of a universal serial bus connection device according to an embodiment of the present invention. Please refer to figure 1 , the connection device 100 provided by the present invention includes a substrate 102 and a terminal element 104 . The substrate 102 may be a printed circuit board on which many circuit elements, such as the circuit element 122 and the circuit element 124 , may be arranged to form a main circuit. The substrate 102 can be at least divided into a body portion 106 and a connection portion 108 , wherein most of the main circuit is disposed on the body portion 106 , and the connection portion 108 can form a connection module with the terminal elements 104 .

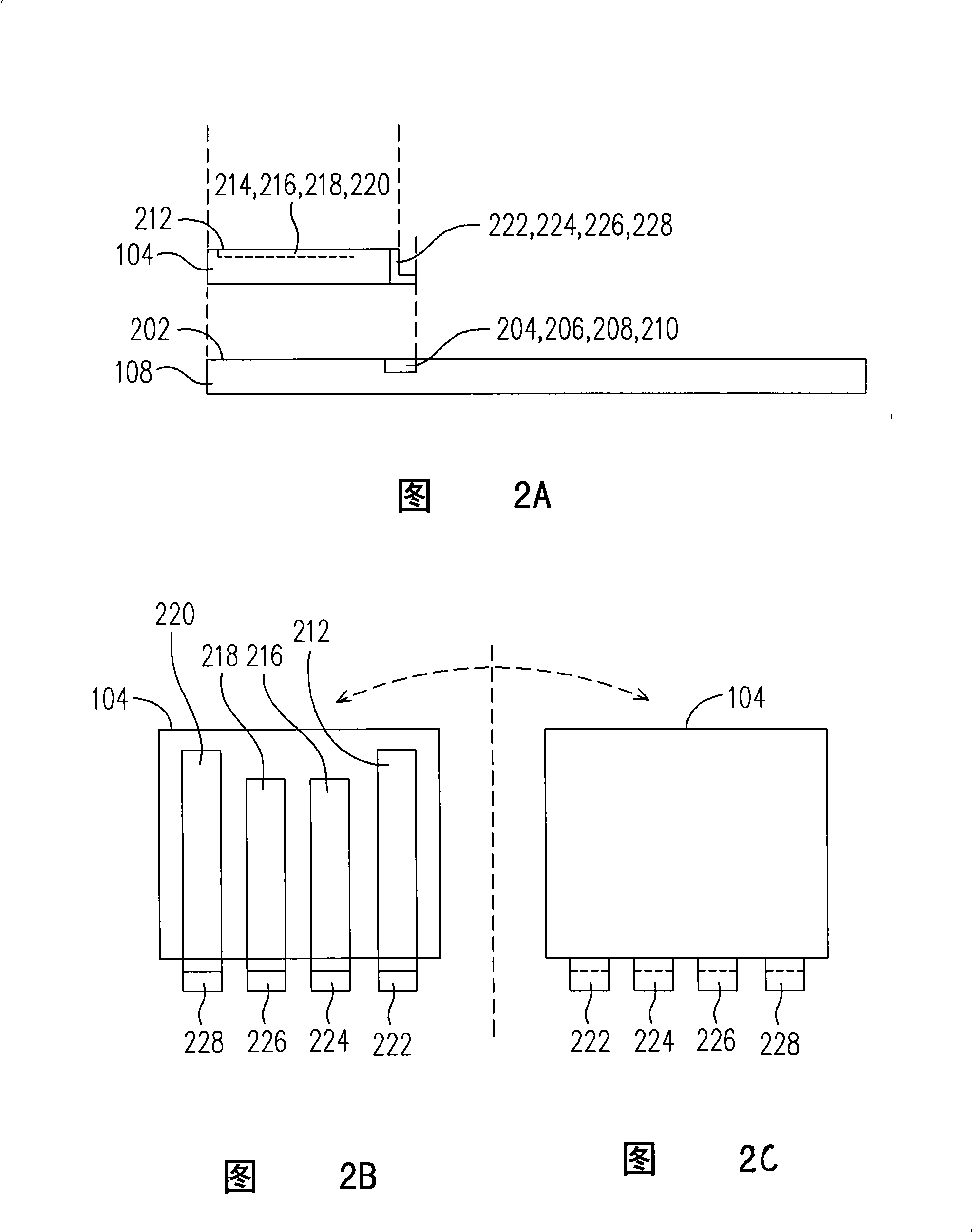

[0026] Figure 2A is shown as figure 1 The cross-sectional structure diagram of the connecting device 100, Fig. 2B is shown as figure 1 The top view of the terminal element 104, while FIG. 2C is shown in accordance with figure 1 A bottom view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com