Process for making two-face jacquard

A production process and fabric technology, applied in the direction of fabric surface trimming, pouring textile material processing, heating/cooling fabrics, etc., can solve the limitations of spandex elastic warp knitted fabrics and other problems, achieve rich hand feel, expand the scope of application, and significantly double-sided effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

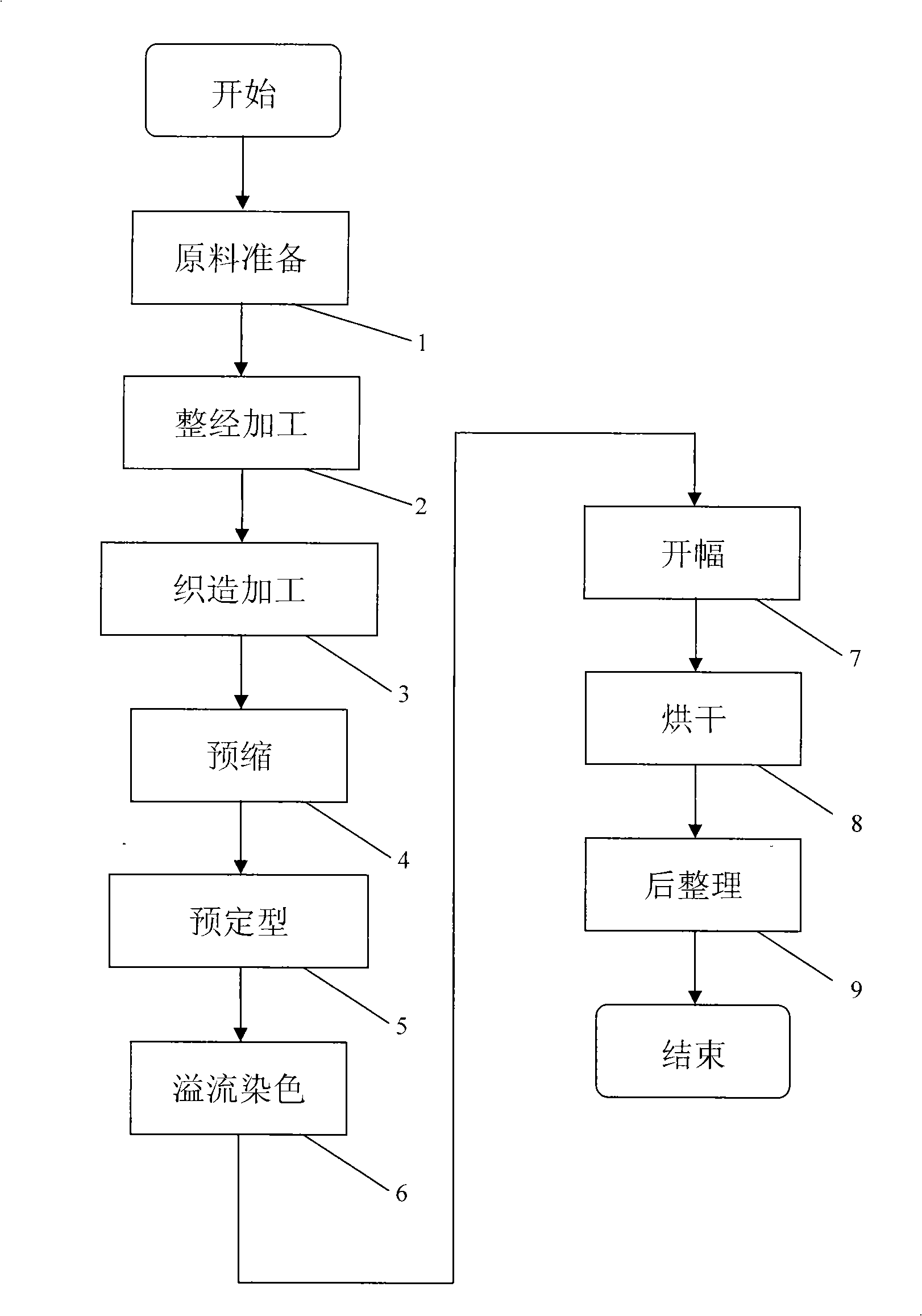

[0036] refer to figure 1 , the manufacturing process of Shuangshuang jacquard fabric, including the following steps in turn:

[0037] Raw material preparation 1: 70D / 24F nylon semi-gloss elastic yarn (630 raw bobbins) with a mass percentage of 84.14% and 70D spandex (628 raw bobbins) with a mass percentage of 15.86% were used as raw materials.

[0038] Warping process 2: stretch warp the raw material of 70D / 24F nylon elastic yarn with a tension of 9-11g / dn, and stretch warp the raw material of 70D spandex with a draft ratio of 60%. Sectional warping is used for operation, and the indoor environmental conditions are relative humidity: 65%-75%; temperature in autumn and winter: 23±2°C, spring and summer: 26±2°C.

[0039] 630 pieces of 70D / 24F nylon elastic yarn raw materials are opened and warped on a DS21 / 30 (NC-2) type warping machine with 6 pan heads per set, and there are two sets (12 pan heads in total). 628 70D spandex raw materials are opened and warped on a DSE21NC typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com