Improved handle assembly method and assembly structure

An assembly structure and assembly method technology, which is applied to the spherical handle of the wing leaf, the handle of the wing leaf, door/window accessories, etc., can solve the problem of distortion, uneven gap between the handle seat and the aluminum alloy handle, and the gap between the handle seat and the door shell Inhomogeneity and other problems, to achieve the effect of reducing the degree of distortion and deformation, good adaptability, and lightening the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

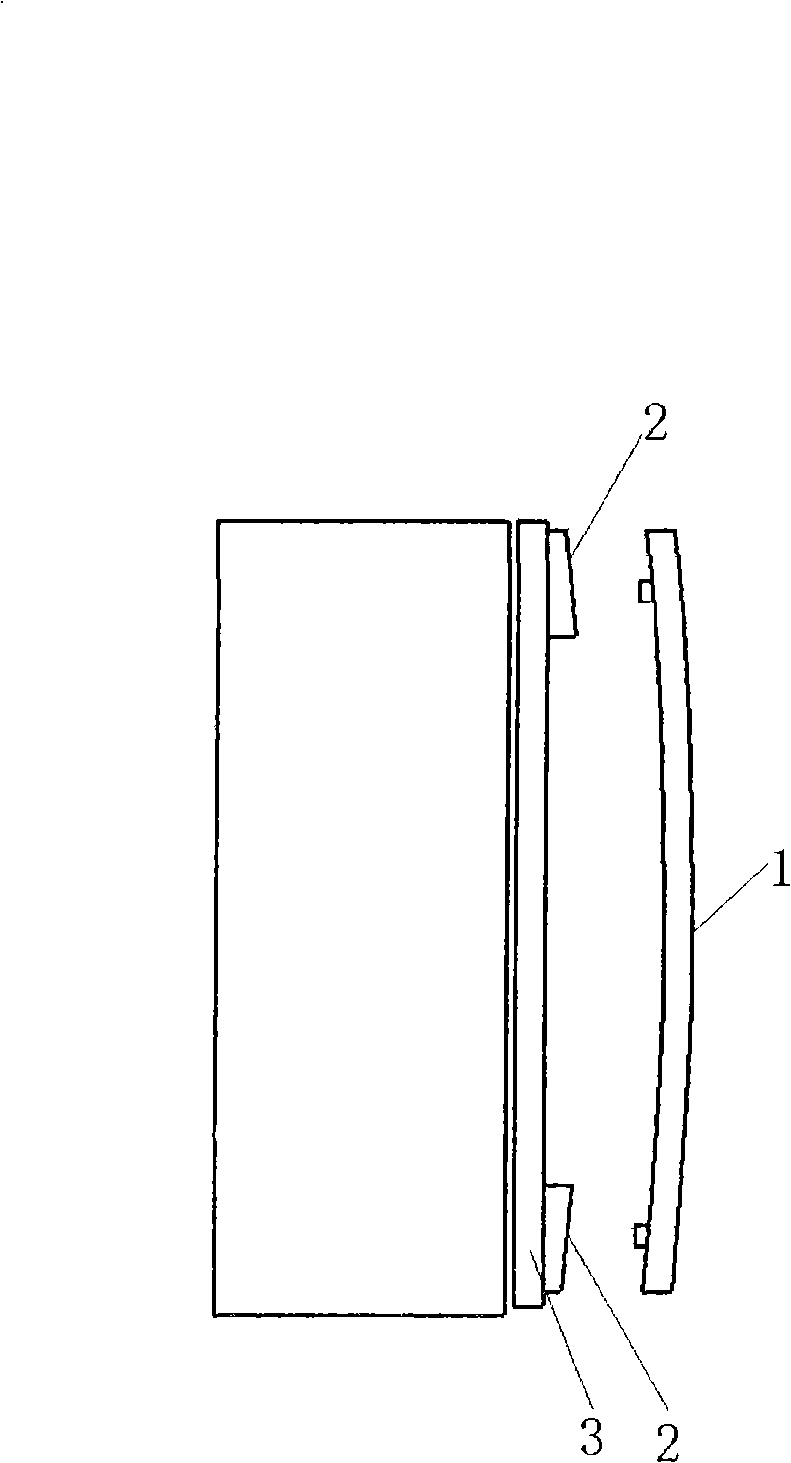

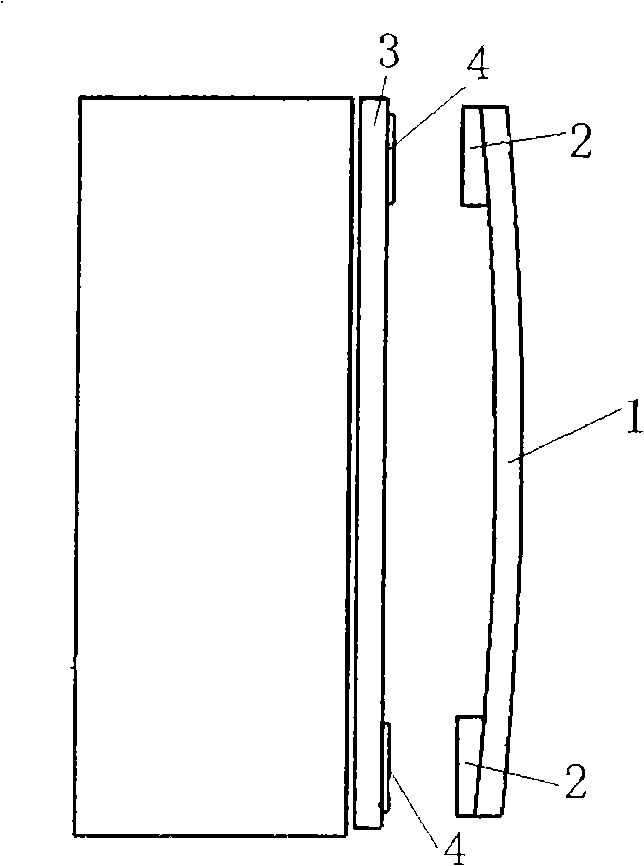

[0014] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0015] The present invention adopts the way that the handle base and the handle are pre-fixed and assembled into a handle assembly, which firstly ensures the complete assembly of the handle base and the handle.

[0016] When the handle assembly is assembled on the door shell, a connecting base is pre-assembled on the door shell, and then the handle assembly is assembled on the connecting base. The connecting base is used as an intermediate connecting body to connect the door shell and the handle assembly. Compared with the original assembly method, this assembly method transfers the screw fastening force from the handle base to the connection base, which greatly reduces the burden on the handle base and effectively reduces the degree of twisting and deformation of the handle base. After the connecting base and the handle assembly are assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com