Single side disc protecting box and optical disc read-write apparatus matching therewith

A single-sided technology for reading and writing equipment, applied in the field of mechanical disc fixing mechanism and optical disc reading and writing equipment, can solve the problems of complex mechanical movement, unguaranteed disc release effect, and increased cost, so as to achieve simple structure and easy disc clamping Effect guarantee, the effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

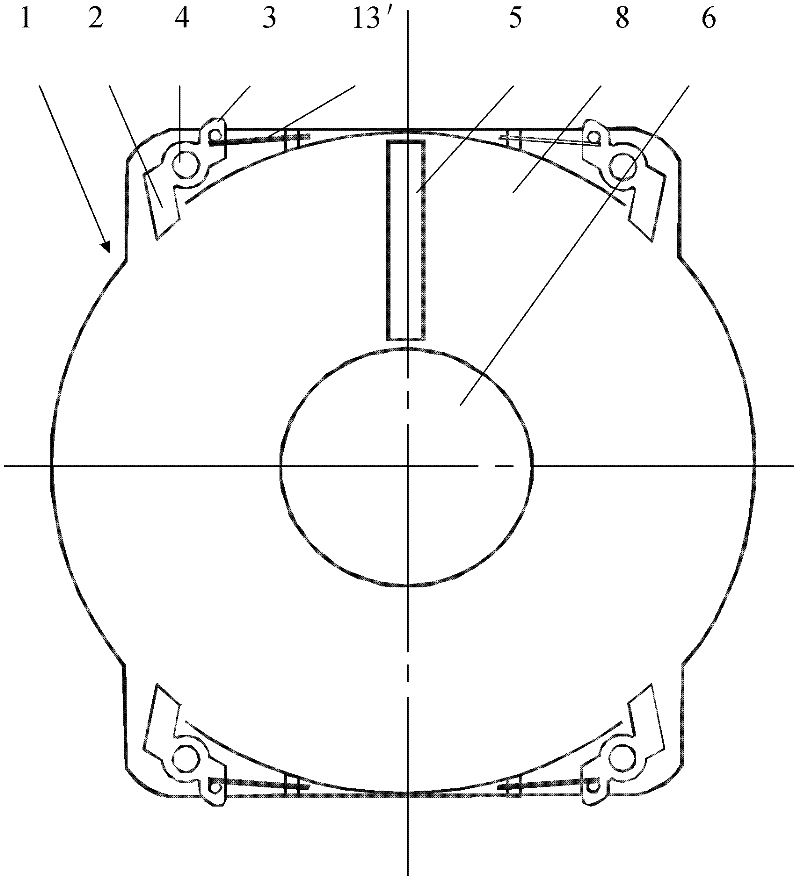

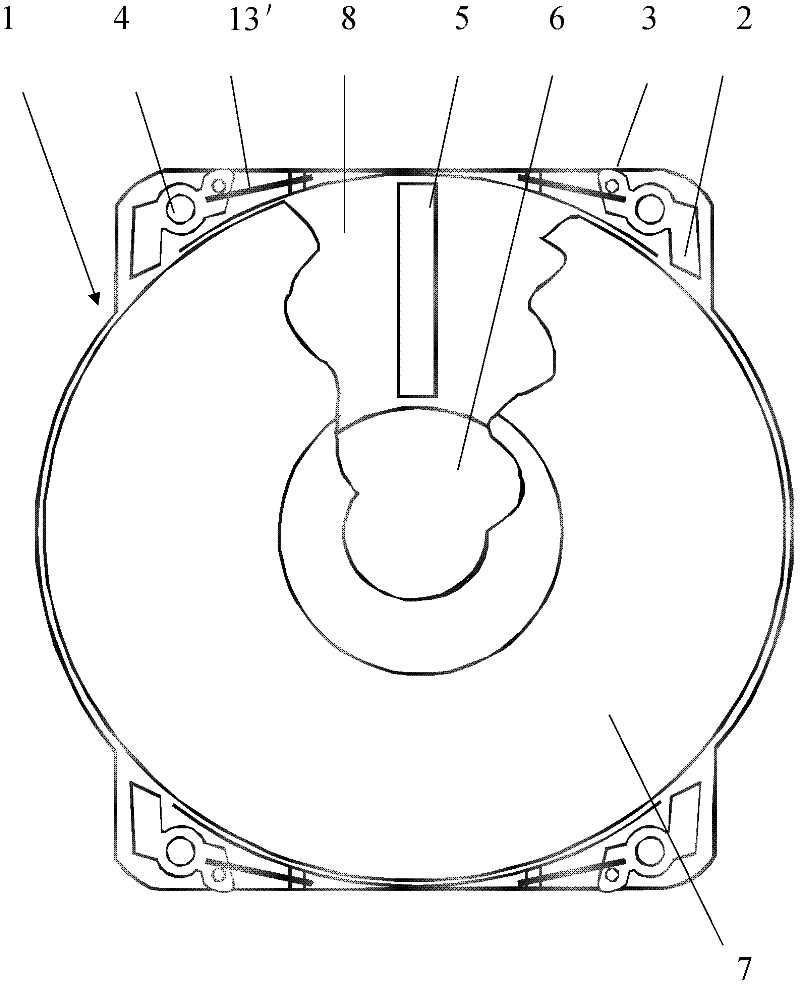

[0062] Such as figure 1 , 2 shown.

[0063] The single-sided disc guard case 1 is provided with a circular disc slot 8, which can hold a disc 7, and the middle part of the disc slot 8 is provided with a circular top disc hole 6, and the diameter of the top disc hole 6 is larger than that of the optical disc. It is advisable that the diameter of the rotating disc motor head of the read-write device is smaller than the diameter of the non-data track area on the inner edge of the optical disc 7. On the radial direction surface of the optical disc groove 8, a read-write head with the same length as the radius of the data track of the optical disc 7 is also provided. Window 5, the width of optical head reading and writing window 5 is advisable to make the optical head of optical disc reading and writing equipment pass through this window to read and write the data of optical disc 7 normally; The periphery of optical disc groove 8 is provided with four expansion areas, for this rea...

Embodiment 2

[0073] Such as Figure 8 , 9 , 10 shown.

[0074] With full reference to the basic design scheme of Embodiment 1, the similarities with Embodiment 1 will not be repeated, and the difference is:

[0075] The automatic extruding device that is provided with on the optical disc reading and writing equipment 14 optical disc trays 15 is to be respectively provided with an extruding body 17 to constitute by the vertical direction at the left and right ends of the optical disc tray 15, and the middle of the extruding bodies 17 is a straight strip Shape, and its two ends have crotch, can directly prevent that single-sided disc protection case 1 can slip with the horizontal plane direction of optical disc bracket 15 when being beneficial to extruding single-sided disc protection case 1.

[0076] Each extrusion body 17 is provided with a rotating mechanism 4 near the lower end of the disc holder 15. The extrusion body 17 is flexibly connected with the optical disk holder 15 by the rot...

Embodiment 3

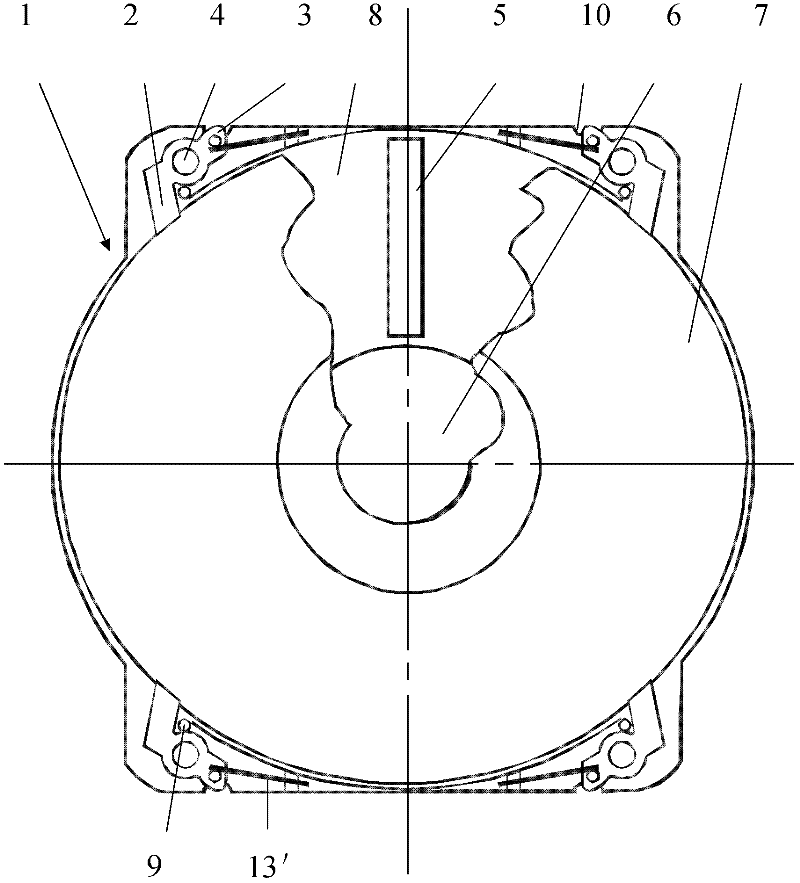

[0080] Such as image 3 , 11 , 12 shown.

[0081] With full reference to the basic design scheme of Embodiment 1, the similarities with Embodiment 1 will not be repeated, and the difference is:

[0082] The specific length of the power body 3 set in the single-sided disc protection box 1 does not exceed the outermost edge of the single-sided disc protection box 1, and each power body 3 is also provided with a squeezing groove 10 at the position of the single-sided disc protection box 1 corresponding to it. , the squeezing groove 10 forms an opening structure on the outermost edge of the single-sided disc protection case 1, and one end of the power body 3 is built into the squeezing groove 10, and the single-sided disc protection case is exposed from the squeezing groove 10 1.

[0083] The spring limit mechanism set on the single-sided disc protection box 1 also includes four limit heads 9, the limit heads 9 are formed by the upward protrusions on the surface of the single-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com