Multiple main thread master-slave type three-helix energy-saving lamp filament and manufacturing method thereof

A manufacturing method and triple-helix technology, which is applied in the field of multi-main and auxiliary triple-helix energy-saving lamp filaments and its production, can solve the problems of unsatisfactory lamp life, insufficient contact area, and low product qualification rate, and achieve Improve the anti-bombardment performance, improve the service life and the effect of high reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

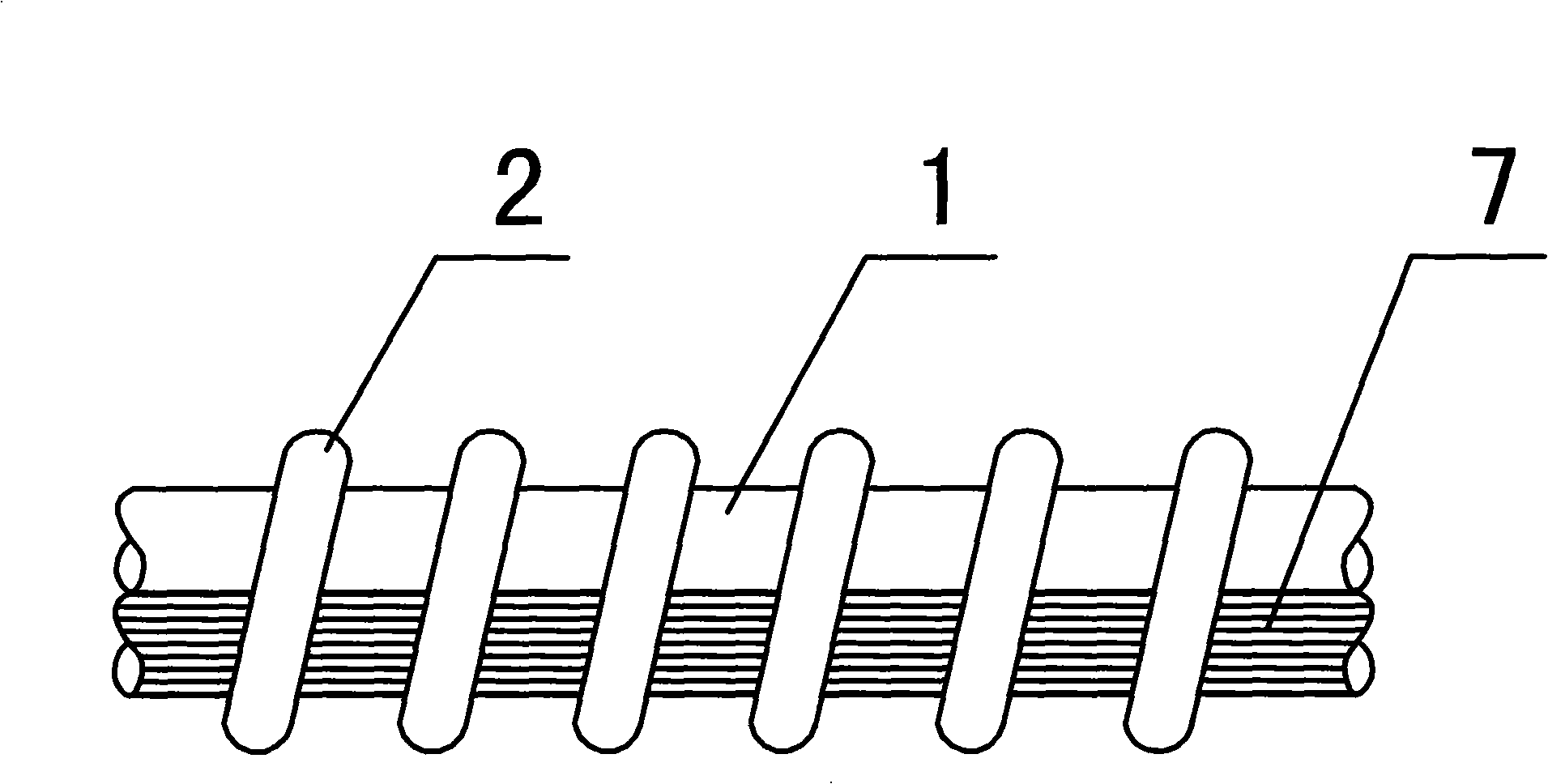

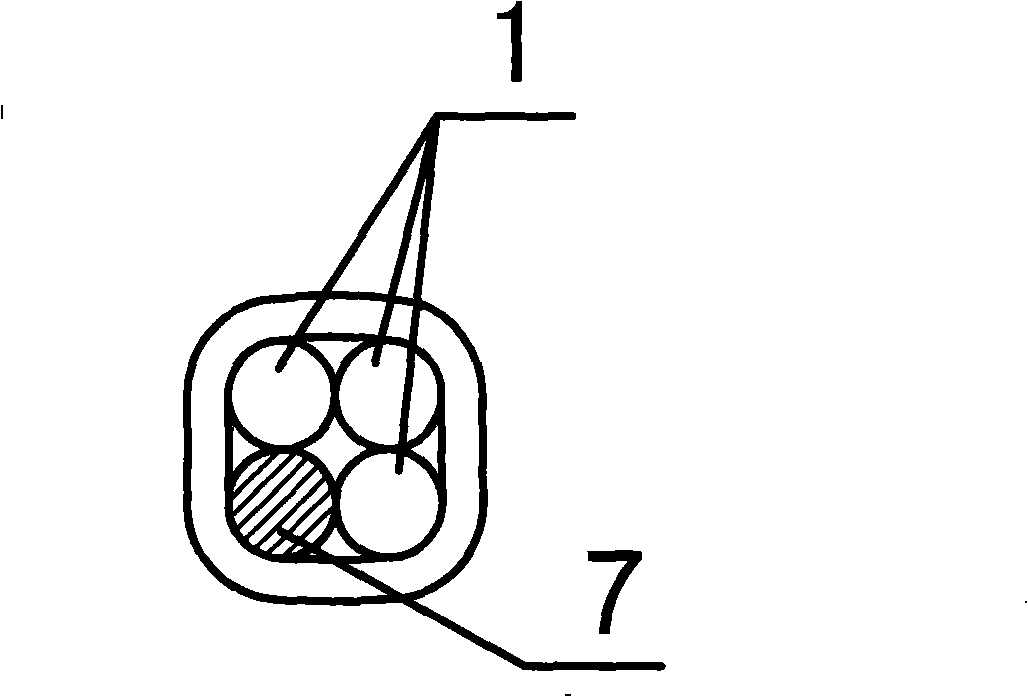

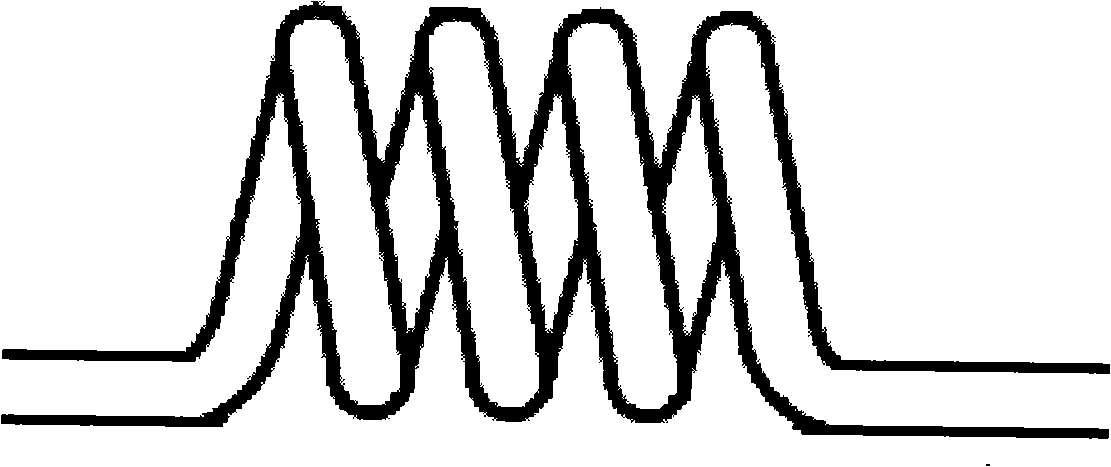

[0025] Example 1. Such as image 3 , 4 As shown, it is spirally wound by the filament secondary winding body 4, wherein the filament secondary winding body 4 is spirally wound by the filament primary winding body 3, as shown in Figure 5 shown. The primary winding body 3 of the filament is wound by three main tungsten wires 1 and one molybdenum wire 7 that are close in parallel, and an auxiliary tungsten wire 2 that is spirally wound on the three main tungsten wires 1 and molybdenum wire 7. into, the three main tungsten wires 1 have the same diameter, such as figure 1 , 2 shown. The diameter and spiral coefficient of the main tungsten wire 1 and the auxiliary tungsten wire 2 should be selected according to the power of the lamp. The diameters of the three main tungsten wires 1 can also be different, and the resistance can be adjusted through different combinations of the diameters of the three main tungsten wires 1 .

[0026] When processing, such as figure 1 , 2 As s...

Embodiment 2

[0027] Example 2. It is spirally wound by the secondary winding body 4 of the filament, wherein the secondary winding body 4 of the filament is wound in a spiral shape by the primary winding body 3 of the filament; Tungsten wire 1, molybdenum wire 7, and two auxiliary tungsten wires 2 that are spirally wound on the three main tungsten wires 1 and molybdenum wire 7 are wound. The diameter of the main tungsten wire 1 and auxiliary tungsten wire 2 is And the spiral coefficient should be selected according to the power of the lamp.

[0028] During processing, the three main tungsten wires 1 and the molybdenum wire 7 are parallel and closely connected together, and the two auxiliary tungsten wires 2 are spirally wound on the three main tungsten wires 1 and the molybdenum wire 7 on an ordinary wire winding machine. Obtain the primary winding body 3 of the filament; then wind the primary winding body 3 of the filament onto the molybdenum core wire 5 on an ordinary wire winding machi...

Embodiment 3

[0029] Example 3. It is spirally wound by the secondary winding body 4 of the filament, wherein the secondary winding body 4 of the filament is wound in a spiral shape by the primary winding body 3 of the filament; Tungsten wire 1, molybdenum wire 7, and three auxiliary tungsten wires 2 that are spirally wound on the three main tungsten wires 1 and molybdenum wire 7 are wound. The diameters of the main tungsten wire 1 and the auxiliary tungsten wire 2 and The spiral coefficient should be selected according to the power of the lamp.

[0030]During processing, the three main tungsten wires 1 and the molybdenum wires are parallel and close together, and the three auxiliary tungsten wires 2 are spirally wound on the three main tungsten wires 1 and the molybdenum wire 7 on an ordinary wire winding machine, and the obtained Filament primary winding body 3; then filament primary winding body 3 is wound onto molybdenum core wire 5 on an ordinary wire winding machine to obtain filamen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com