Vacuum treatment device, vacuum treatment method and storage medium

A vacuum processing device and vacuum processing technology, applied in the direction of flow control of electric devices, gaseous chemical plating, coating, etc., can solve problems such as no discovery, and achieve the effects of component cost suppression, resolution improvement, and good processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

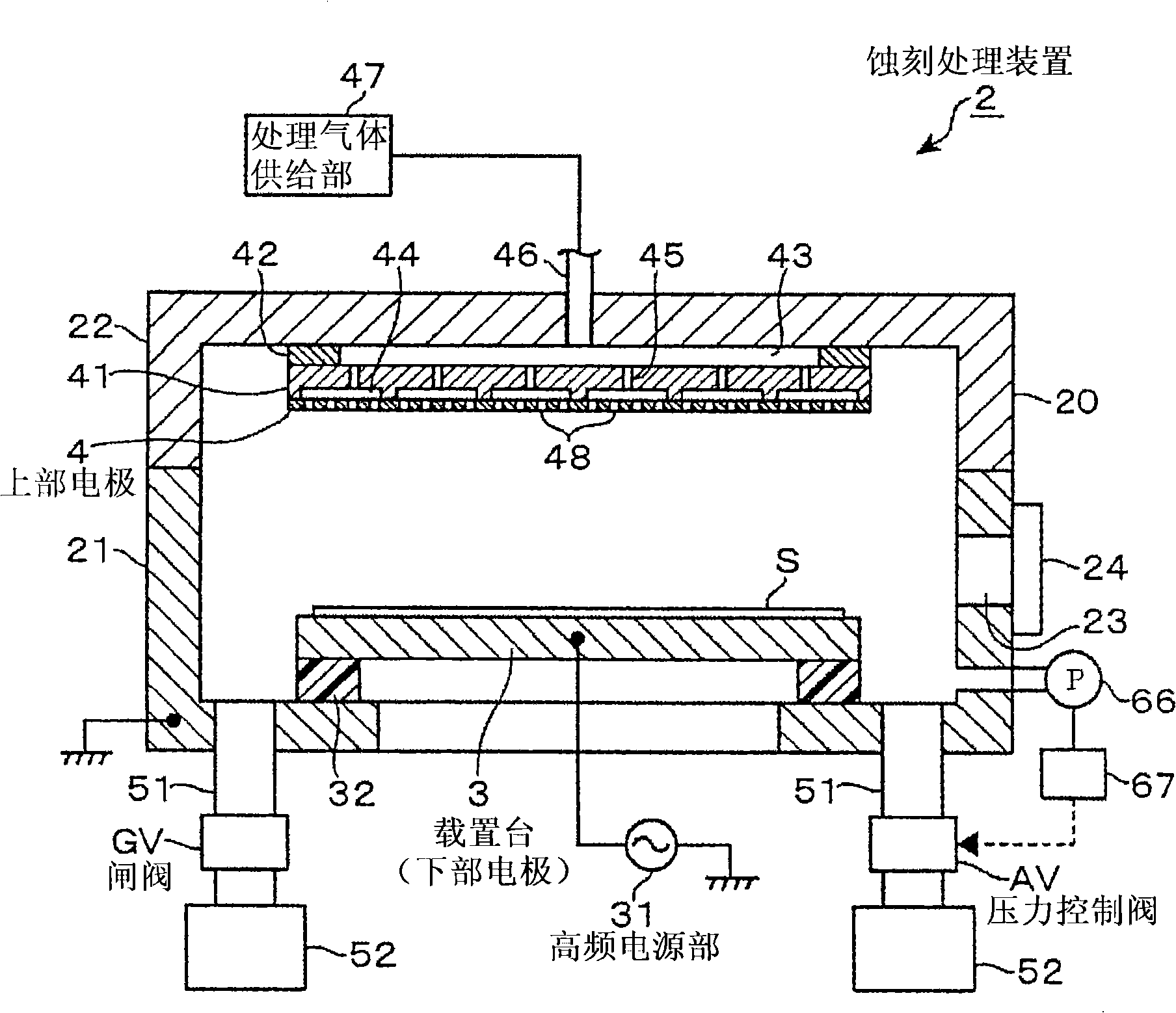

Method used

Image

Examples

Embodiment 1

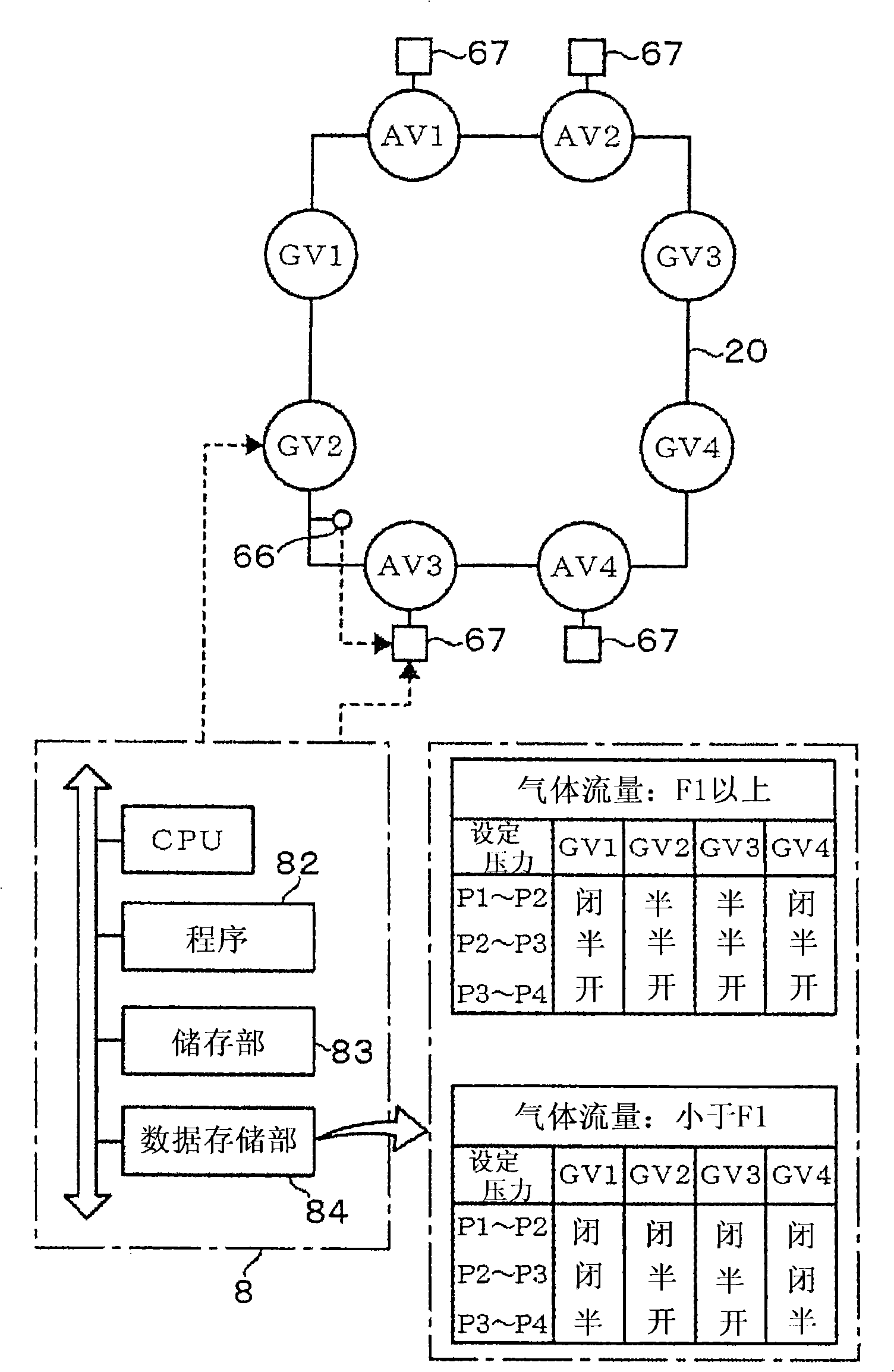

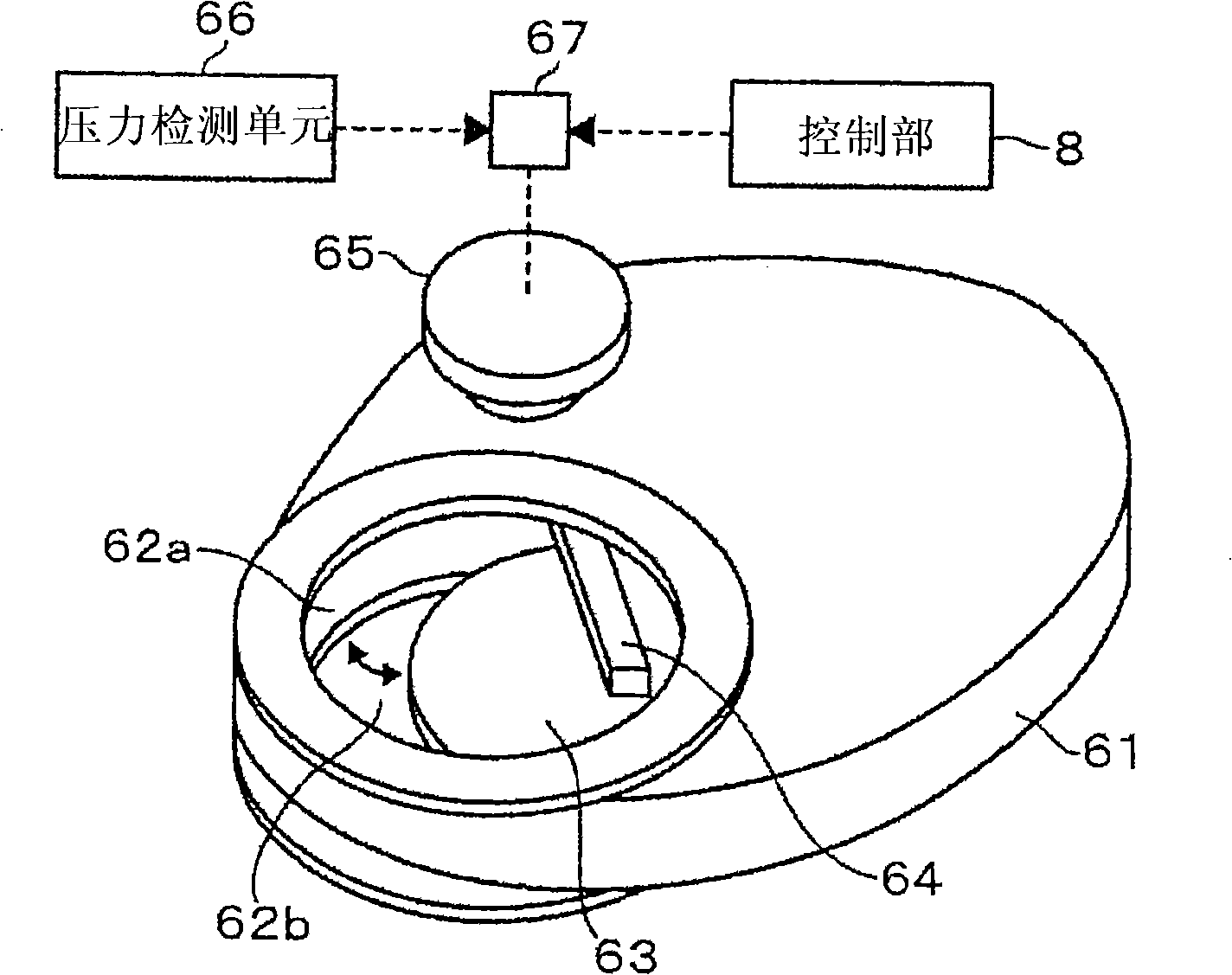

[0084] Pressure control valves are provided on two of the above-mentioned exhaust passages 51, and gate valves GV are provided on the other four exhaust passages 51. The processing container 20 is exhausted, and the relationship between the pressure in the processing container 20 and the opening degree of the pressure control valve AV at that time is obtained. exist Figure 8 The result is indicated by the data of ▲. In the figure, the horizontal axis represents the opening degree of the pressure control valve AV, and the vertical axis represents the pressure of the processing container. At this time, the opening degrees of the two pressure control valves AV are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com