Multi-printing module cycle printing method and apparatus

A technology of rotary printing and printing modules, applied in rotary printing machines, offset rotary printing machines, printing devices, etc., can solve the problems of singleness and low efficiency, and achieve the advantages of improving efficiency, enriching colors, and reducing investment costs and production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

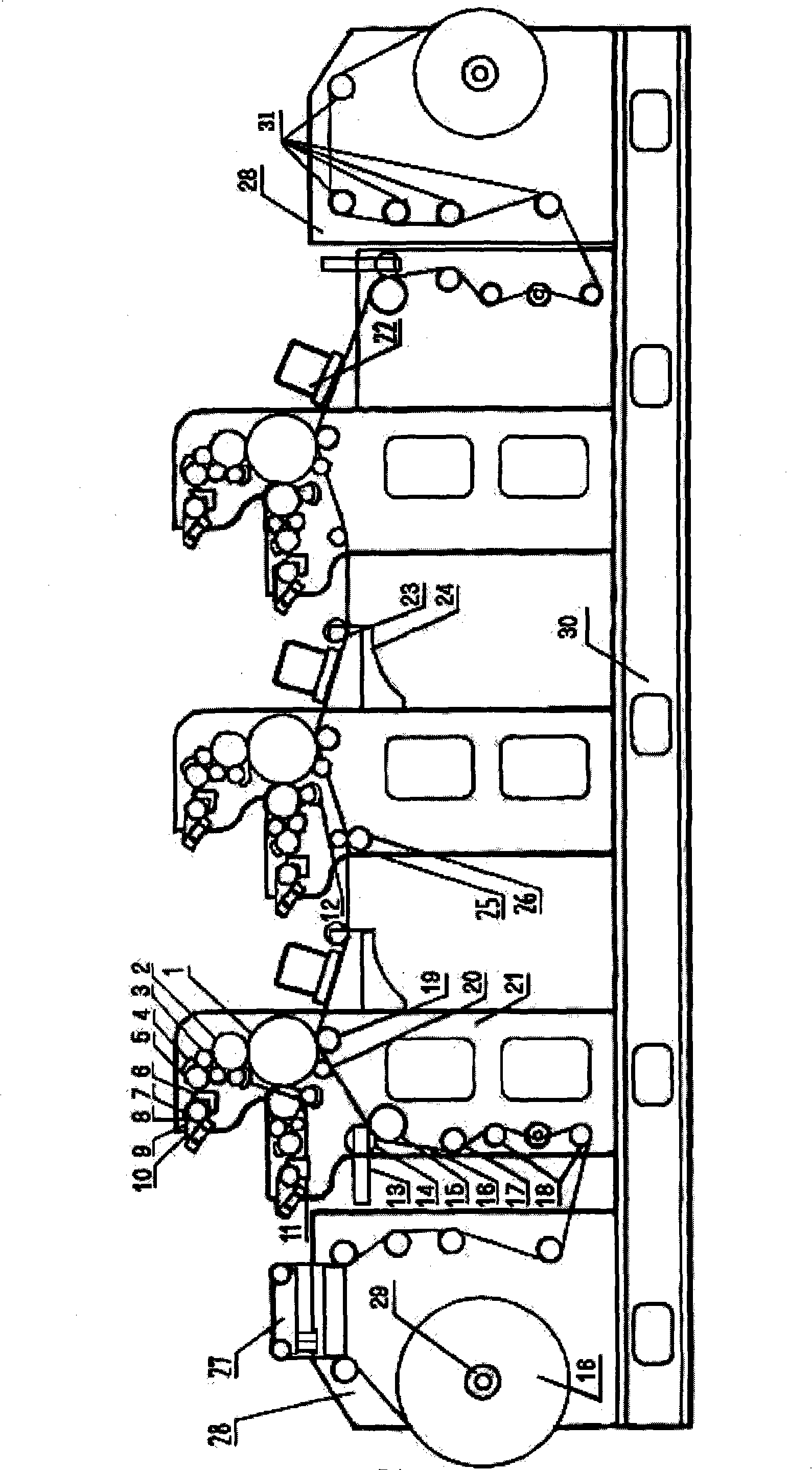

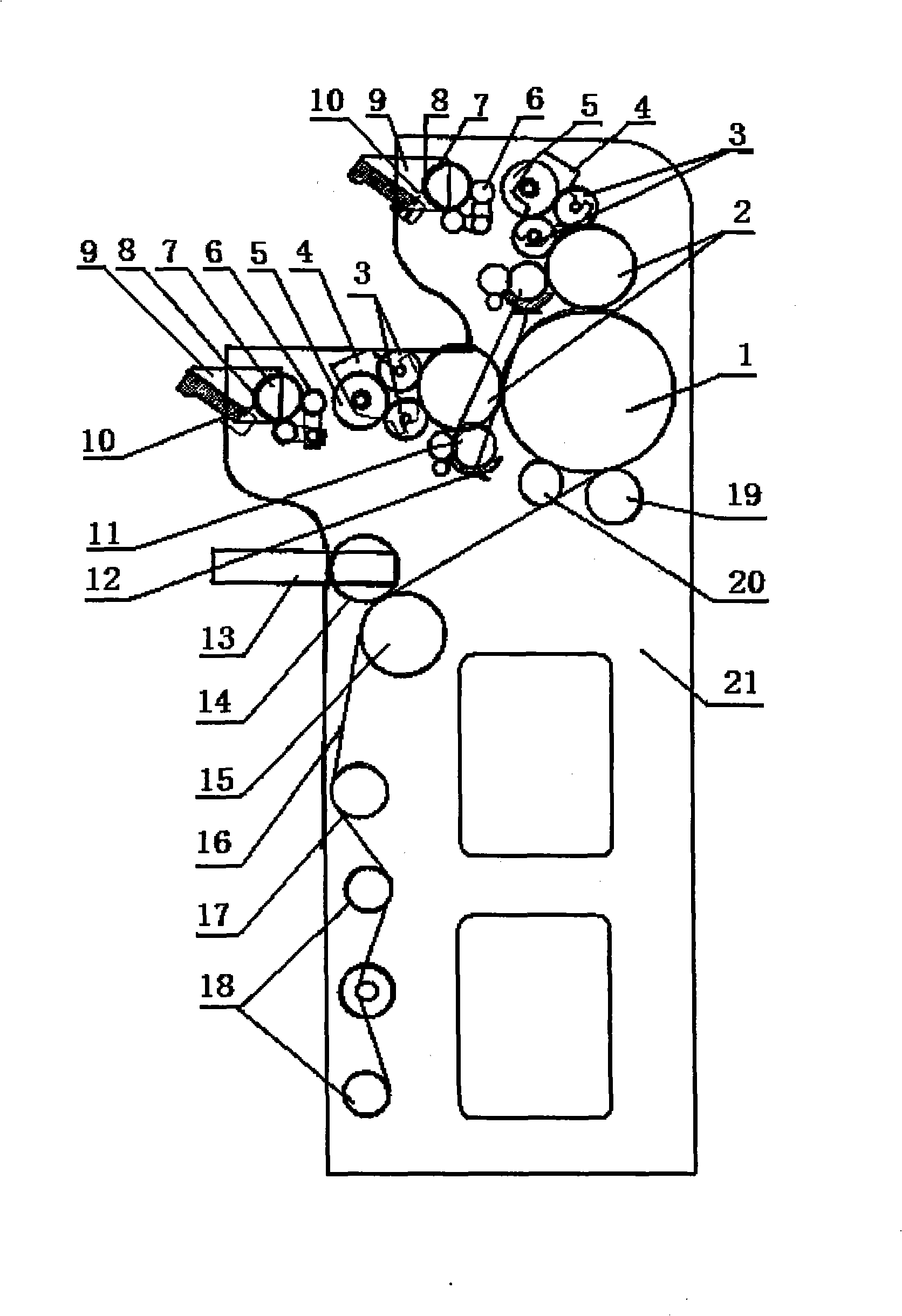

[0022] combine figure 1 , figure 2 The multi-printing module rotary printing device of the present invention shown in the present invention is on the whole machine base 30. When in use, the paper 16 is led out on the paper roll side plate 28 through the paper expansion shaft core 29, and is guided by the paper guide roller 31 to correct the deviation. Adjust the position of the device 27, and then transition to the printing mold base 21. At the same time, the ink in the ink fountain 9 flows out and contacts with the doctor blade 10 with a certain inclined angle to form a cut surface. When the ink fountain roller 8 rotates, The ink scraper 10 scrapes off the excess ink on the roller surface, so that the ink on the ink roller is uniform, and the ink fountain roller 8 drives the ink transfer cam 7 to rotate, and drives the ink transfer roller 6 to receive the ink from the ink fountain roller 8 and connect with the string. The ink rollers 5 contact and separate continuously to r...

Embodiment 2

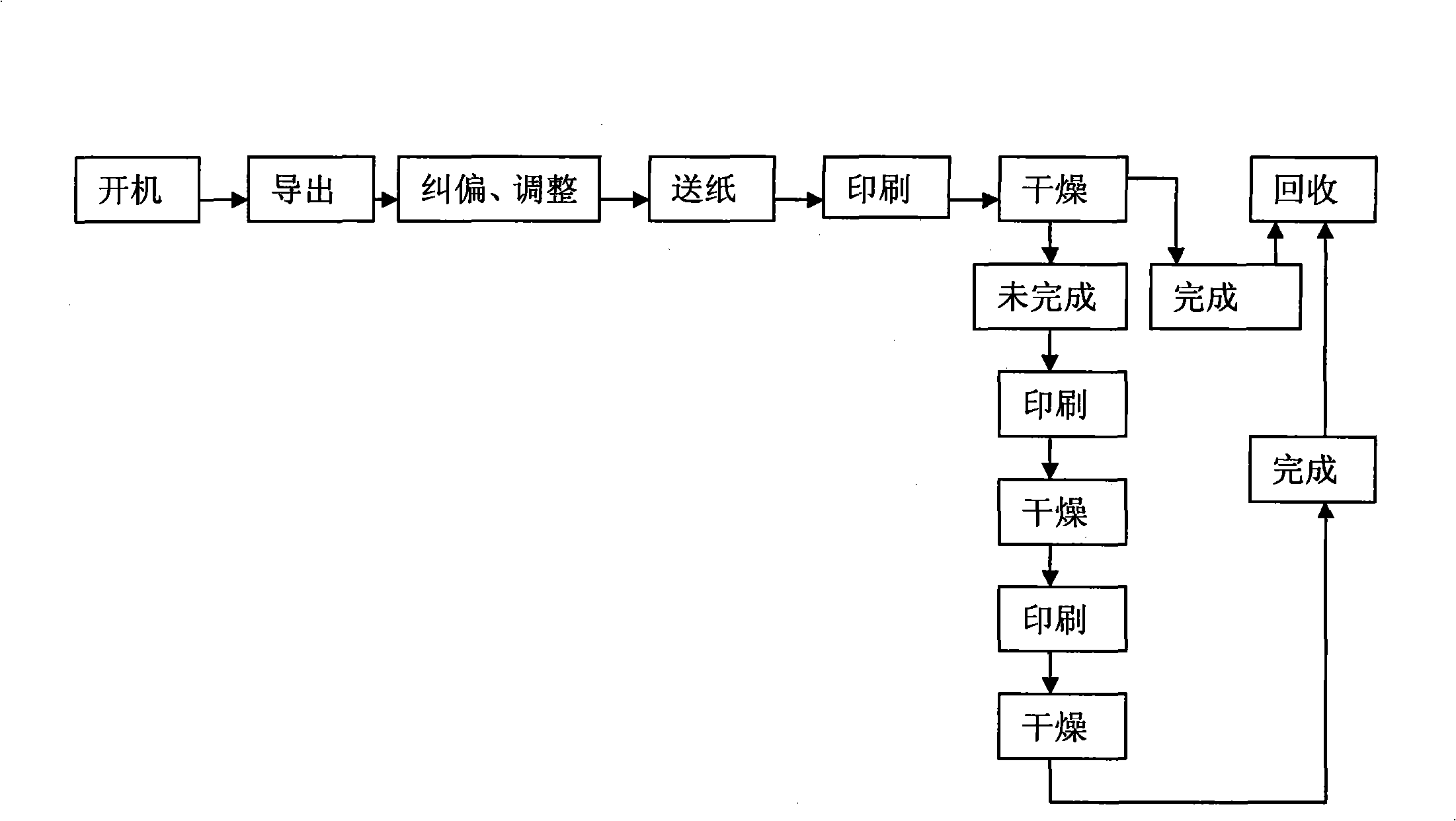

[0024] combine figure 1 , image 3 The multi-printing module rotary printing device of the present invention shown in the present invention is on the whole machine base 30. When in use, the paper 16 is led out on the paper roll side plate 28 through the paper expansion shaft core 29, and is guided by the paper guide roller 31 to correct the deviation. Adjust the position of the device 27, and then transition to the printing mold base 21. At the same time, the ink in the ink fountain 9 flows out and contacts with the doctor blade 10 with a certain inclined angle to form a cut surface. When the ink fountain roller 8 rotates, The ink scraper 10 scrapes off the excess ink on the roller surface, so that the ink on the ink roller is uniform, and the ink fountain roller 8 drives the ink transfer cam 7 to rotate, and drives the ink transfer roller 6 to receive the ink from the ink fountain roller 8 and connect with the string. The ink rollers 5 contact and separate continuously to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com