High-performance sand wall coating and preparation method thereof

A high-performance technology for sand-wall coatings, applied in the field of high-performance sand-wall coatings and their preparation, can solve problems such as low tinting power and hiding power, easy water absorption and whitening of coatings, easy refraction and fading of coatings, etc., to achieve Strong tinting power and hiding power, good anti-corrosion and anti-mildew effect, good coating decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

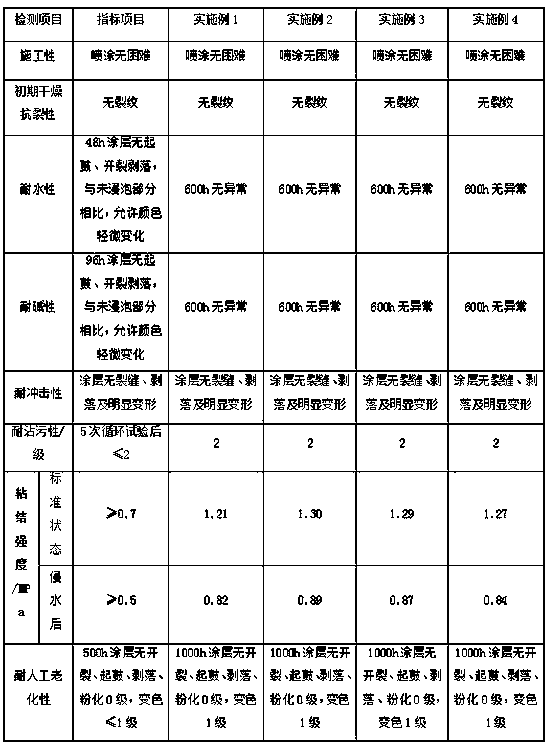

Examples

Embodiment 1

[0029] Raw materials (by weight):

[0030] 15 parts of base material, 60 parts of natural colored sand, 3 parts of film-forming aid (propylene glycol butyl ether), 0.1 part of wetting agent (polyoxyethylene alkylphenol ether), 0.5 part of titanium dioxide, 0.1 part of dispersant, anti-corrosion 0.1 part of mold agent, 0.1 part of multifunctional additive, 0.05 part of defoamer, 0.01 part of thickener, 10 parts of deionized water.

[0031] Preparation:

[0032] S1. Put deionized water into the disperser first, then add half of the total amount of dispersant, wetting agent, and defoamer to the disperser in turn under the condition that the speed of the disperser is 300-400rpm. Increase the speed to 1000rpm and stir for 5-10min, then adjust the speed to 600rpm, slowly add titanium dioxide, after the addition, adjust the speed to 1200rpm, disperse at high speed for 5min, then add the film-forming aid and stir for 5min;

[0033] S2. Slowly add pure acrylic emulsion under low-spee...

Embodiment 2

[0036] 20 parts of base material, 70 parts of natural colored sand, 4 parts of film-forming aids (propylene glycol butyl ether and propylene glycol methyl ether acetate), 0.2 parts of wetting agent (polyoxyethylene fatty alcohol ether), 1 part of titanium dioxide, dispersant 0.2 parts, 0.2 parts of anti-corrosion and anti-mold agent, 0.3 parts of multi-functional additives, 0.1 parts of defoamer, 0.05 parts of thickener, 12 parts of deionized water.

[0037] The preparation method of above high-performance sand wall-like coating is the same as embodiment 1.

Embodiment 3

[0039] 25 parts of base material, 75 parts of natural colored sand, 5 parts of film-forming aid (propylene glycol methyl ether acetate), 0.3 parts of wetting agent (polyoxyethylene alkylphenol ether and polyoxyethylene fatty alcohol ether), 1.5 parts of titanium dioxide 0.25 parts of dispersant, 0.3 parts of antiseptic and antifungal agent, 0.4 parts of multifunctional additives, 0.15 parts of defoamer, 0.1 part of thickener, and 14 parts of deionized water.

[0040] The preparation method of above high-performance sand wall-like coating is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com