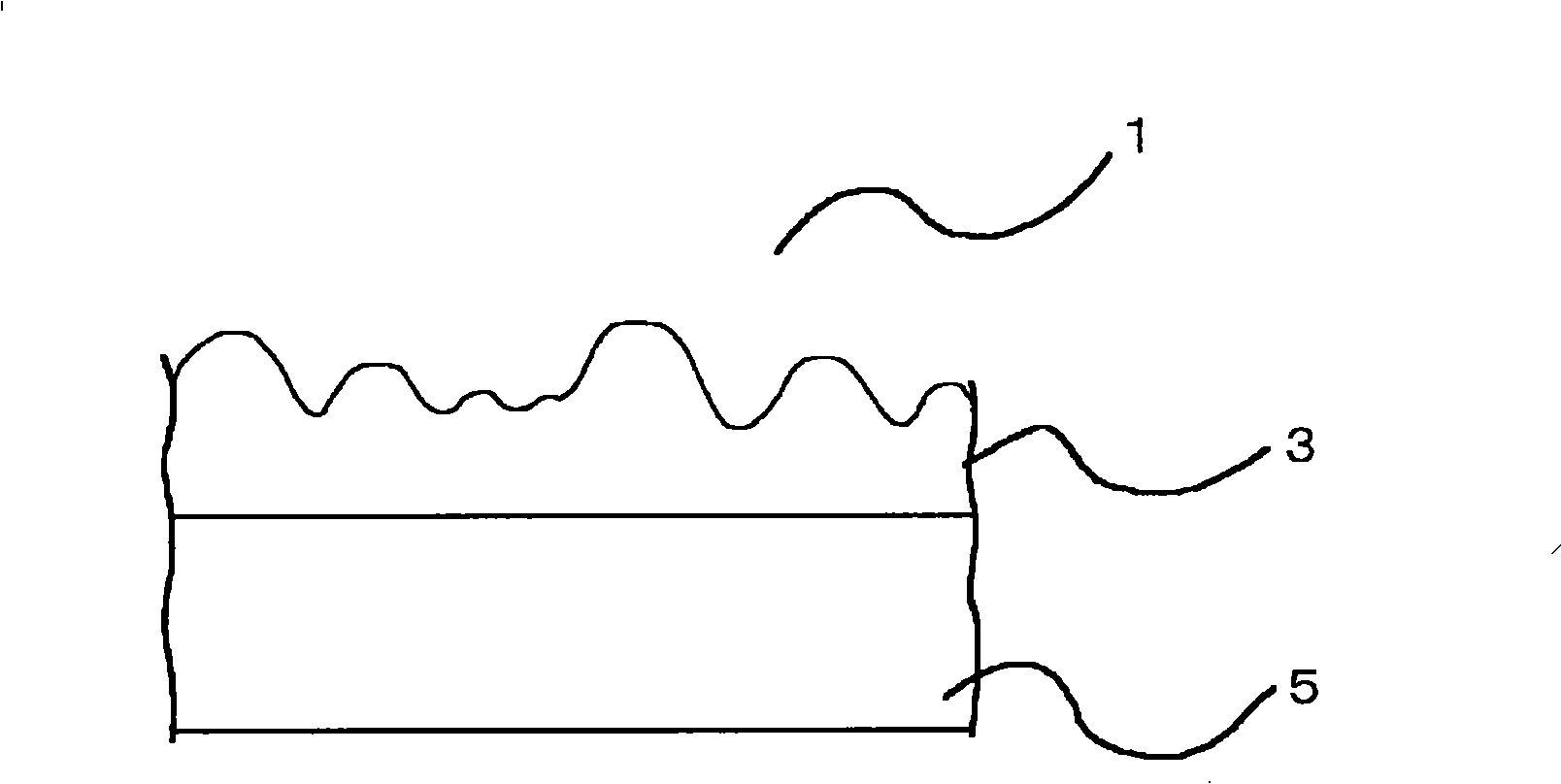

Antiblocking photocurable resin composition, antiblocking structure coating the same on substrate and production method thereof

A curable resin and anti-blocking technology, applied in the direction of coating, layered products, etc., can solve the problems of deterioration of coating film properties, vulnerability to damage, and damage to photochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

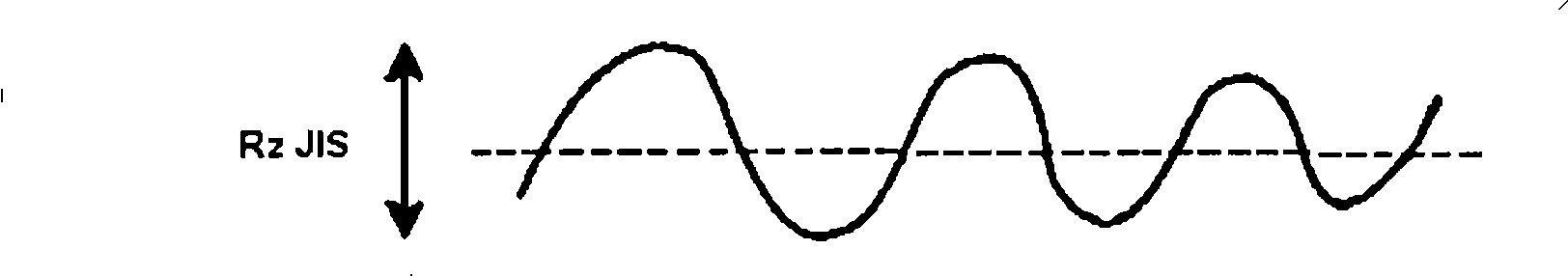

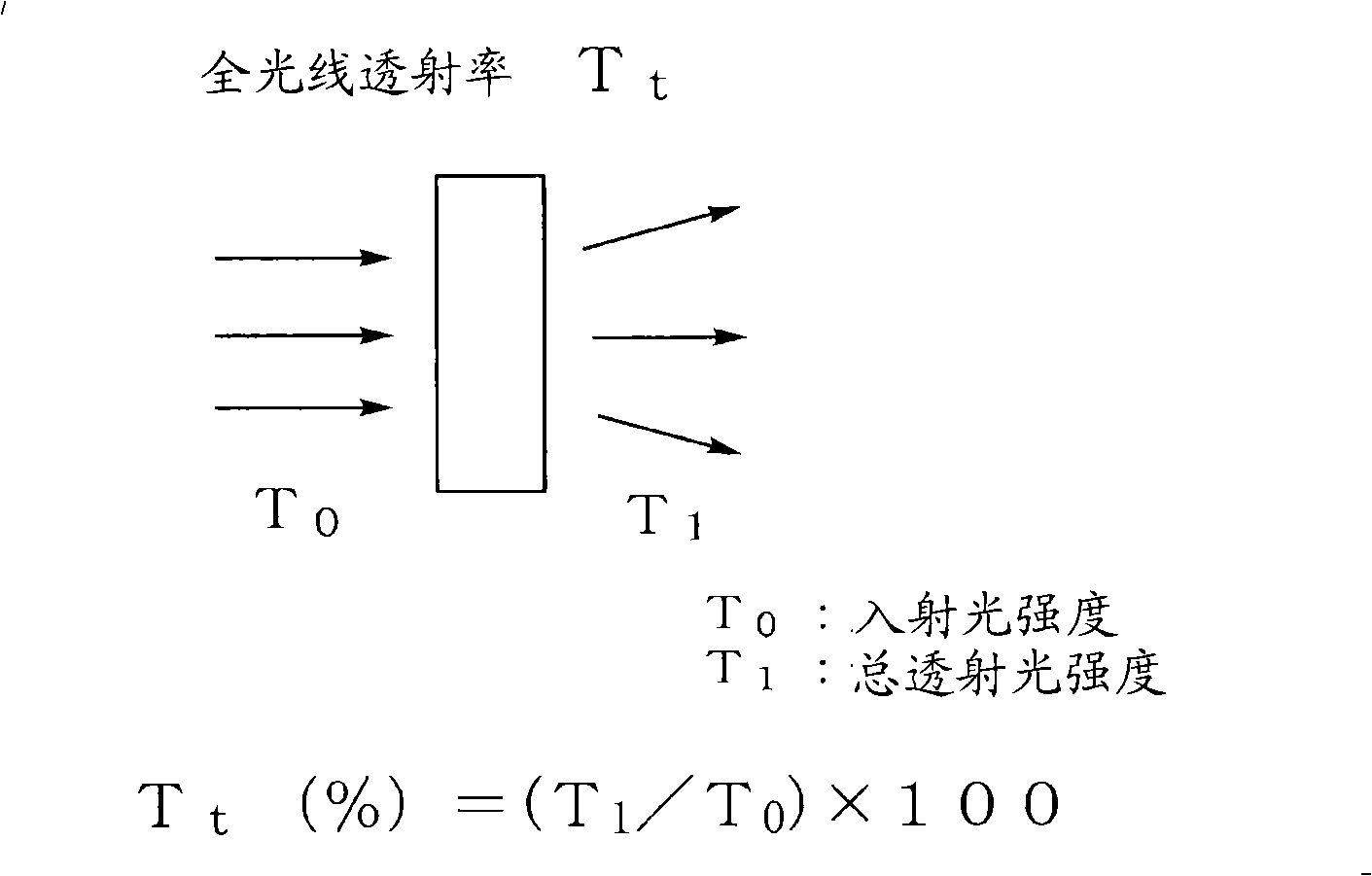

Method used

Image

Examples

Embodiment 1

[0160] 1 part by weight of the acrylic copolymer of Preparation Example 1 (SP value of the resin: 10.2, Tg: 113° C., weight average molecular weight Mw = 5200) as the first component, 99 parts by weight of Aronix M305 (Toagosei Co., Ltd. pentaerythritol triacrylate, SP value: 12.7), as a silicone compound 0.1 parts by weight FM-7711 (Chitsuso Co., Ltd. reactive silicone, number average molecular weight Mn = 1000), 7 parts by weight 2-Methyl-1-[4-(methylthio)phenyl]-2-morpholinopropan-1-one, which is a photoinitiator, is mixed in isopropanol as a solvent to make a non-volatile component rate up to 40% by weight of the solution.

[0161] The solution was coated on a PET film substrate (100 μm) with a bar coater (No.10) at 23°C, dried at 80°C for 1 minute to form a film with a thickness of 5 μm, dried to remove the solvent, and then irradiated with an ultra-high pressure mercury lamp Ultraviolet (350nm), energy up to 300mJ / cm 2, to solidify the film. For the obtained anti-bloc...

Embodiment 2-9

[0190] In the same manner as in Example 1, the antiblocking layered structures of Examples 2 to 9 were prepared and evaluated in the same manner as in Example 1. Tables 1 and 2 show the results. In embodiment 2-9, change the acrylic copolymer used in embodiment 1 into listed in the table, used monomer, silicone compound, use and embodiment 1 identical, embodiment 5 and In Example 9, the following silica particles were used, and in Example 6, the following acrylic particles were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com