Polythene tube composition for mining

A polyethylene pipe and composition technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., to achieve the effect of excellent antistatic and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

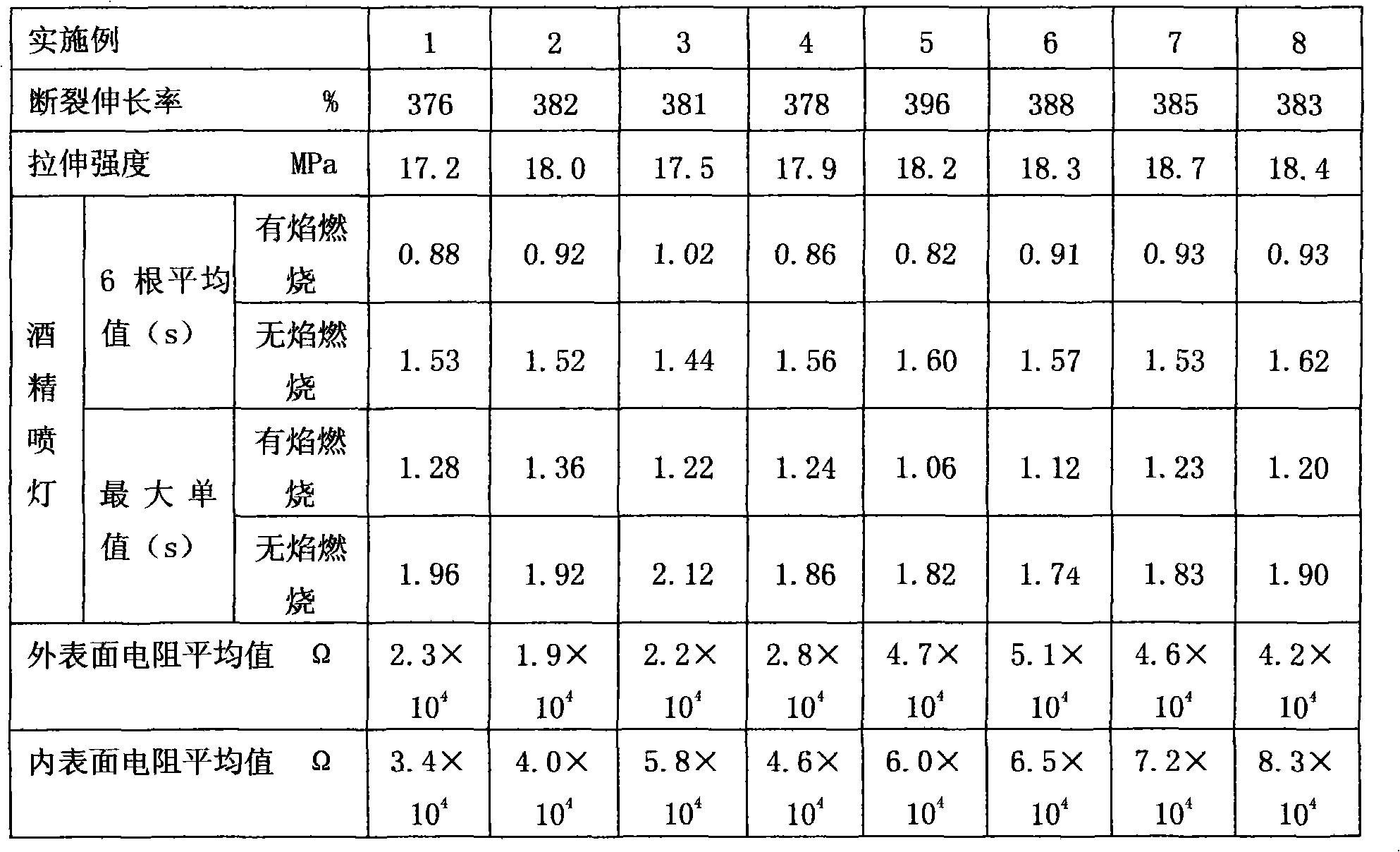

Examples

preparation example Construction

[0040] The pipe preparation method of the present invention includes the following steps: adding polyethylene and antistatic and flame-resistant functional masterbatch raw materials or adding non-essential components such as: antioxidants, ultraviolet light stabilizers, processing aids, these raw materials are added Extruder, after plasticizing and extruding, vacuum cooling and shaping, after cooling, it can be cut to length.

[0041] In the pipe preparation example of the present invention, the following processing parameters are used to manufacture pipes:

[0042] Processing temperature: 180-220℃

[0043] Host speed: 75-85rpm

[0044] Cooling water temperature: 28-20°C

[0045] Host torque: 65-70%

[0046] Melt pressure: 25-28Mpa

[0047] Output: 550-620Kg / h

[0048] In the present invention, the cooling water used is preferably soft water, and the temperature of the cooling water has a gradient distribution of decreasing temperature. In the example of the present inve...

example 1

[0080] An example recipe is:

[0081] i) 89 parts by weight of polyethylene; ii) 11 parts by weight of antistatic and flame retardant functional masterbatch;

example 2

[0083] An example recipe is:

[0084] i) 82 parts by weight of polyethylene; ii) 16 parts by weight of antistatic flame retardant functional masterbatch iii) 1 part by weight of antioxidant 2,4,6-tri-tert-butylphenol; iv) 2-hydroxyl-4- Methoxy-5-sulfobenzophenone; v) 0.5 parts by weight of oxidized polyvinyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com