Scintillator panel and radiation detector

A scintillation screen and radiation technology, applied in the field of scintillation screens, can solve the problems of easy scattering of visible light, scattering of visible light entering a protective film, deterioration of image resolution characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0027] Figure 1 to Figure 4 Embodiment 1 is shown.

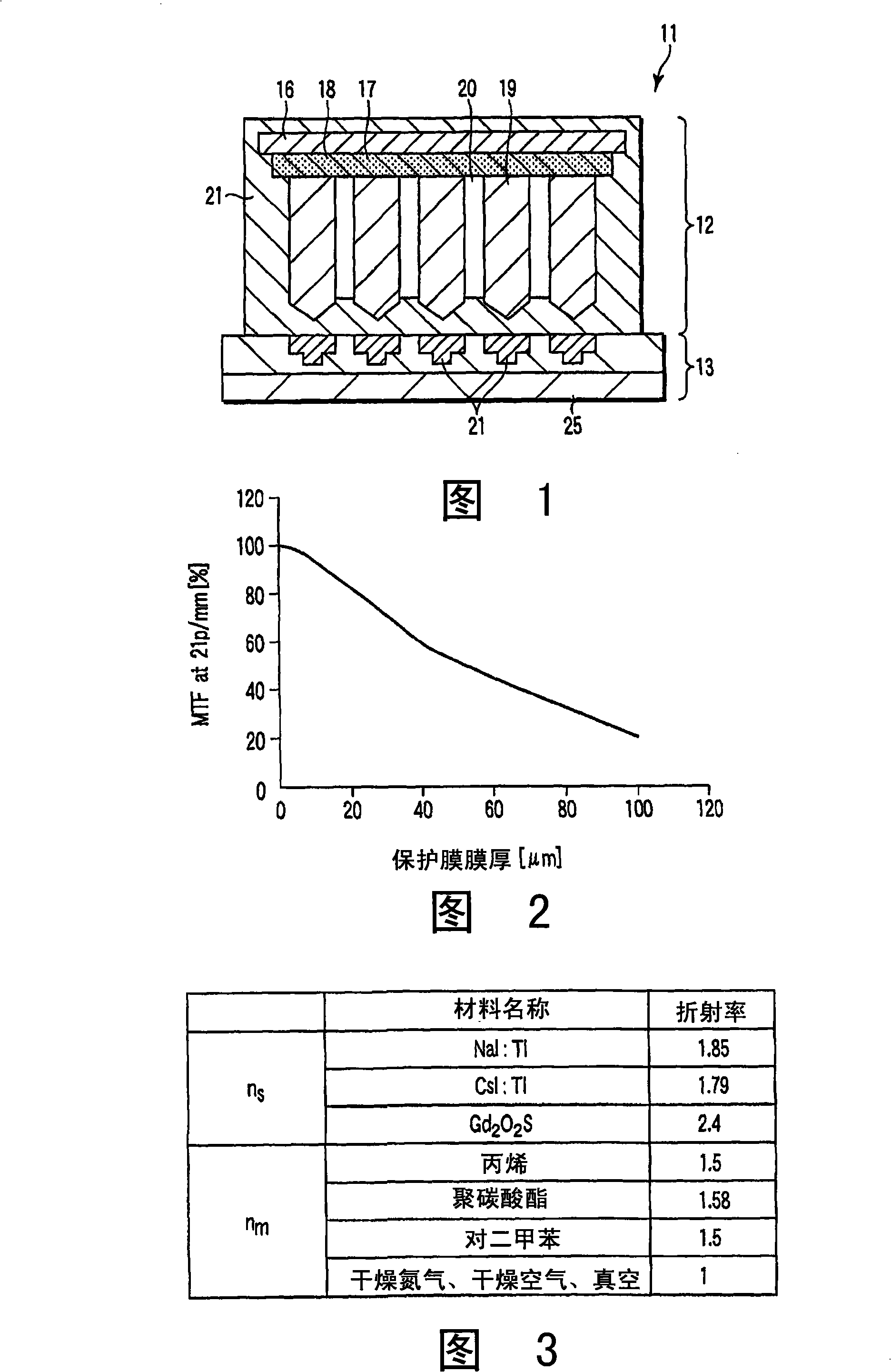

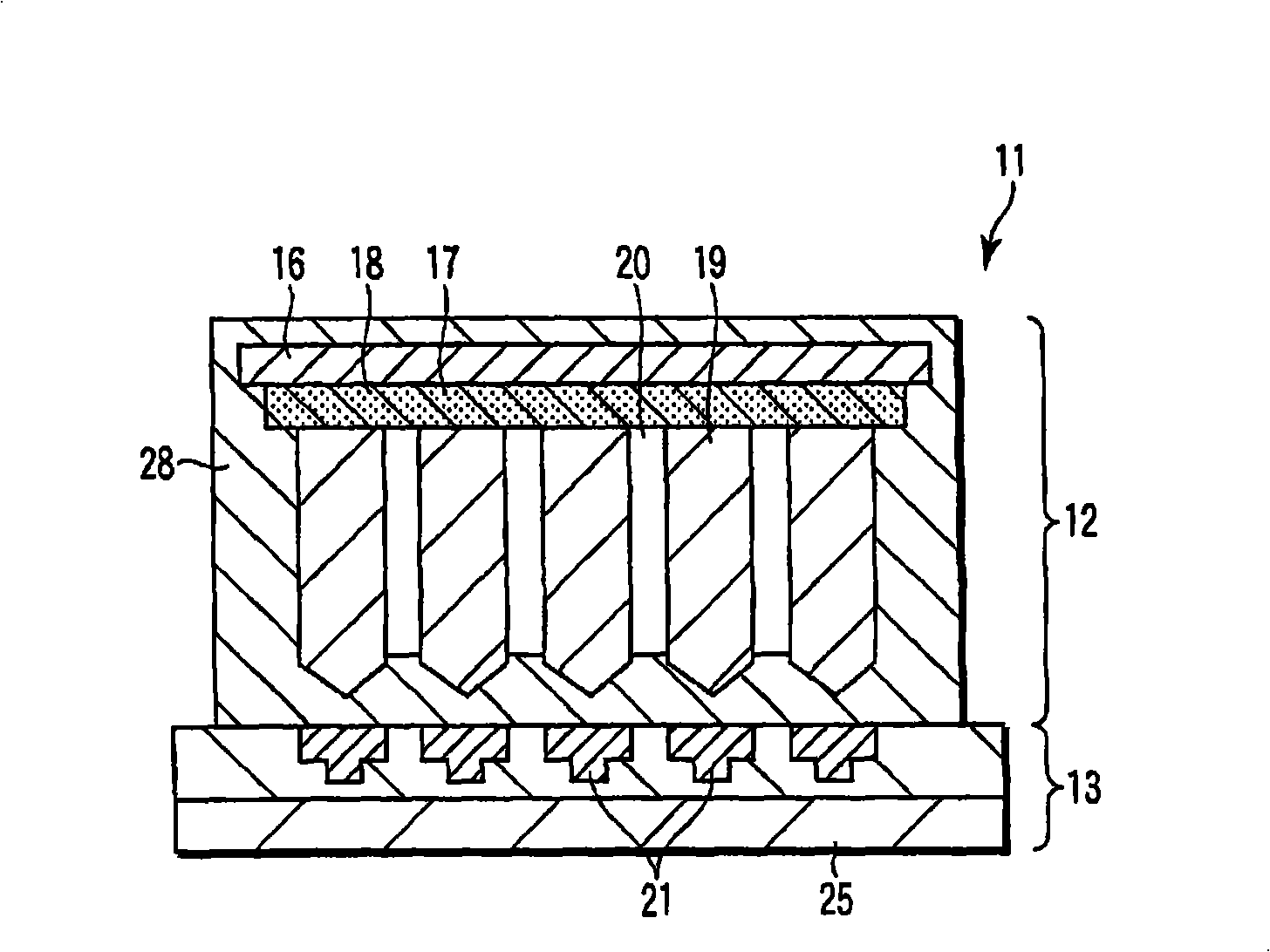

[0028] As shown in FIG. 1 , the radiation detector 11 includes a scintillation screen 12 and a photoelectric conversion element 13 .

[0029] The scintillation screen 12 has a radiation-permeable support base 16 formed by curing carbon fibers with resin, and a light-reflecting material dispersion film 17 is formed on the surface of the support base 16 in a planar shape. The light-reflecting material dispersion film 17 is made of, for example, an organic material such as p-xylene. Light reflective material particles 18 of an inorganic material are dispersed in this light reflective material dispersion film 17 . Therefore, this light reflective material dispersion film 17 also functions as a light reflective film.

[0030] A scintillation layer 19 capable of converting incident radiation into visible light is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com