Clutch type electric screw press

An electric screw and clutch technology, which is applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of low service life, difficulty in replacement, and increased cost of lubricating oil conditions, and achieves strong reliability and safety, and process adaptability The effect of wide range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

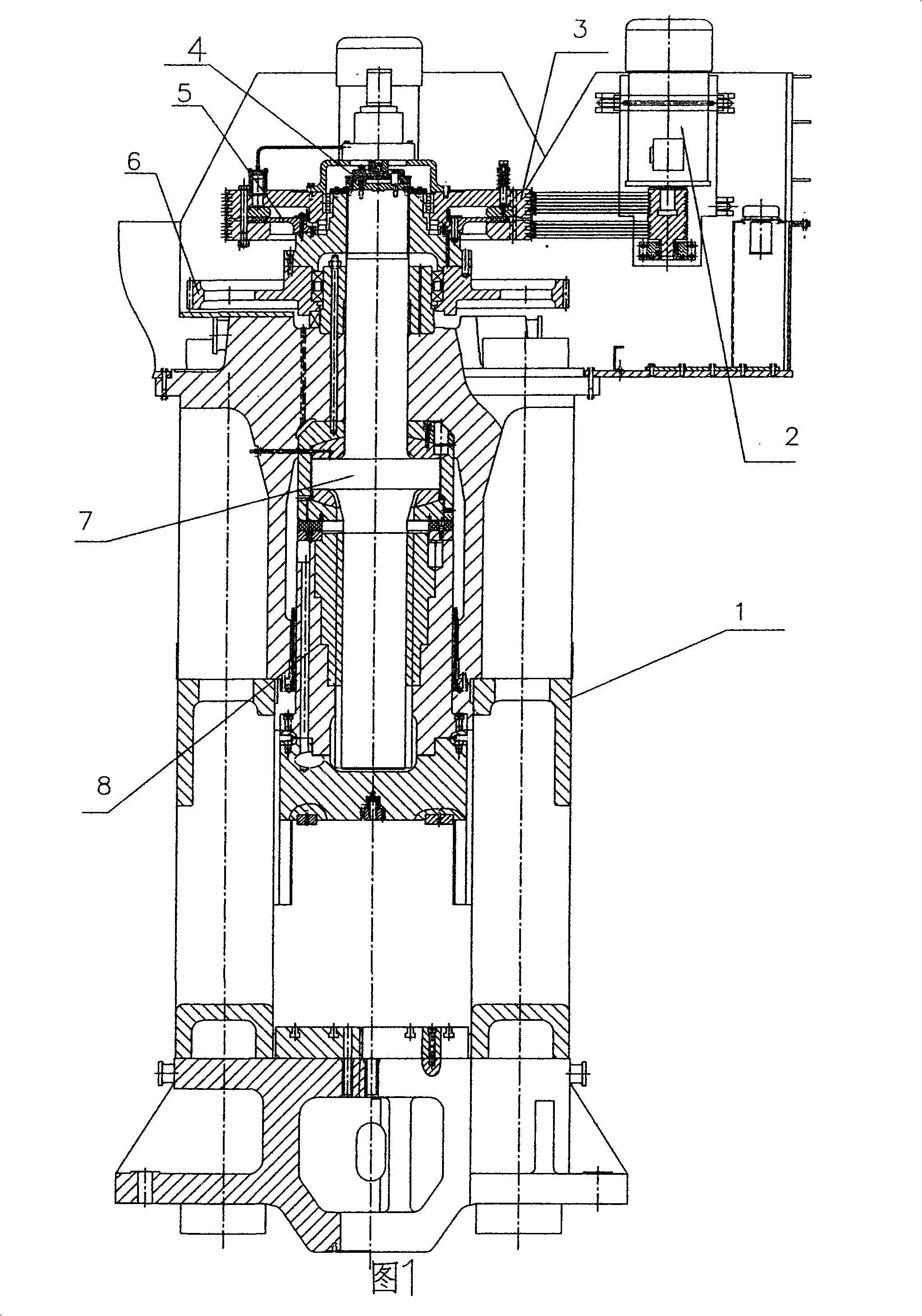

[0012] In Fig. 1, the clutch-type electric screw press of the present invention includes a frame 1, a drive motor 2 installed above the frame, a clutch flywheel 3 driven by the drive motor, and a clutch 4 installed on the clutch flywheel. After the clutch is engaged The friction disc 5 that drives it to rotate, is fixed together with the friction disc and is driven by the electric motor 6, the screw rod 7 fixed on the electric flywheel, and the slide block 8 with internal thread installed on the bottom of the screw rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com