System for reducing electrophoretic liquid deposition slag

An electrophoretic solution and slagging technology, applied in electrophoretic plating, electrolytic coatings, coatings, etc., can solve the problems of frequent slagging operations, high production costs, environmental pollution, etc., to reduce the amount of slagging, increase flow rate, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

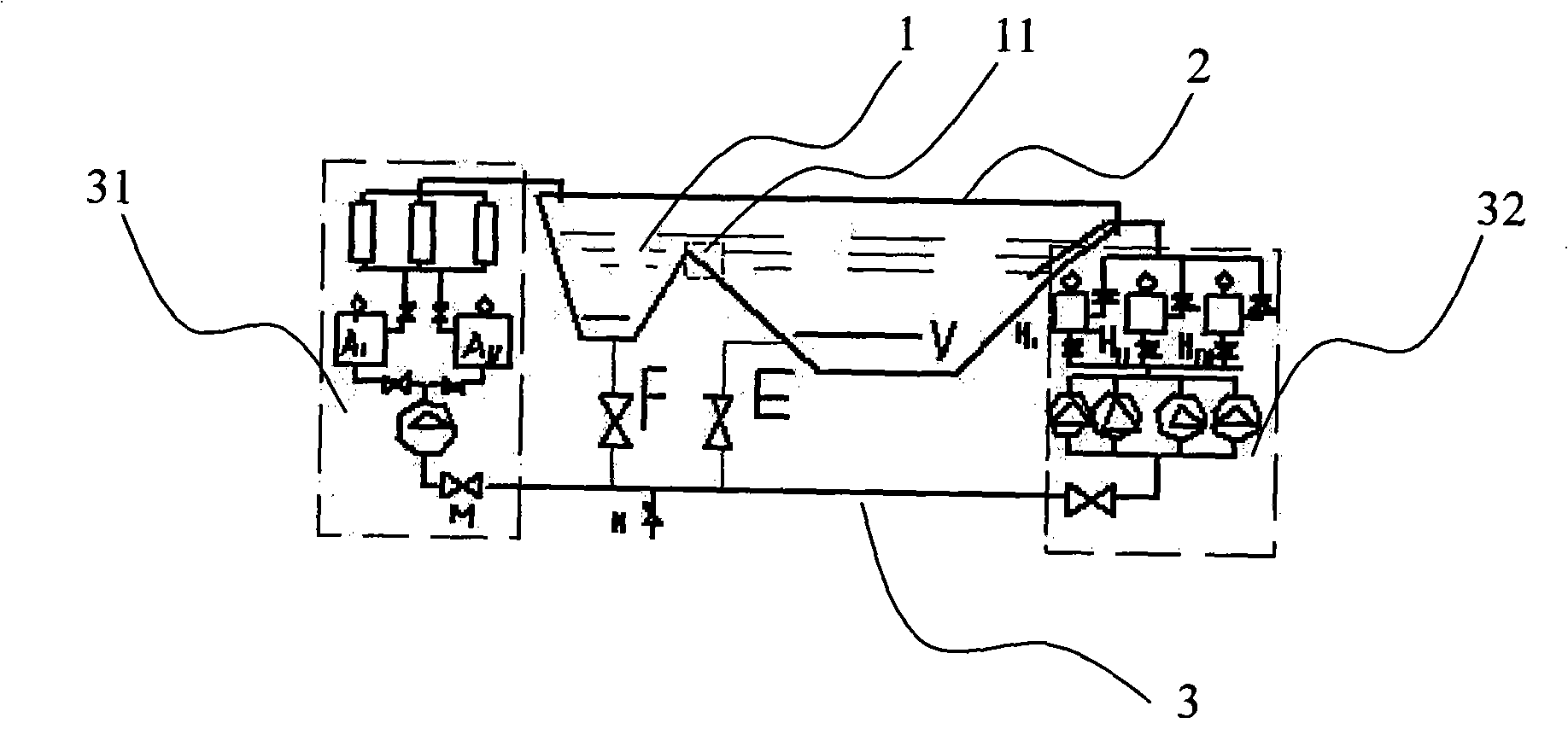

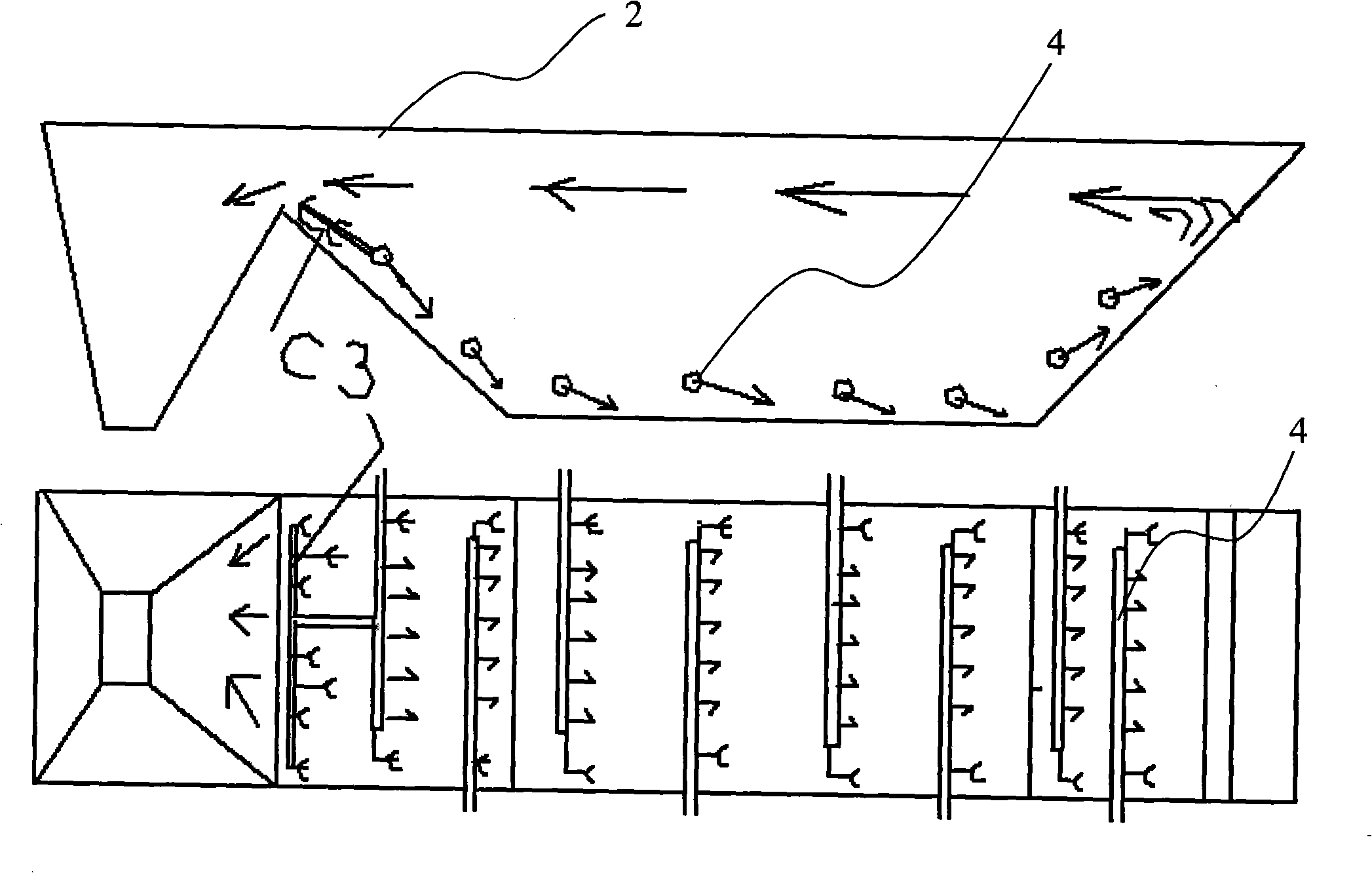

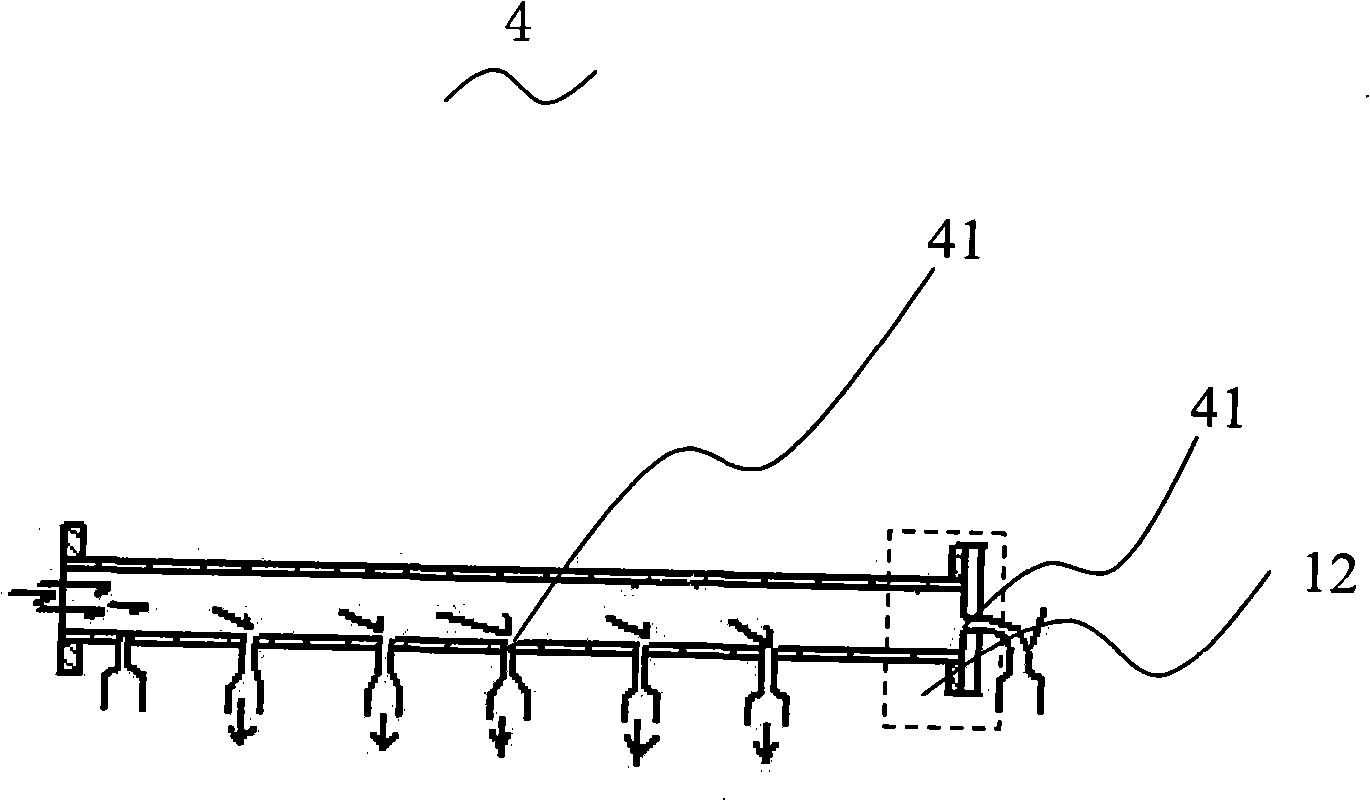

[0034] Such as Figure 1 to Figure 4 As shown, a system for reducing deposition and slagging of electrophoretic fluid includes a tank body 2 for containing electrophoretic fluid 1 and a pipeline pipeline 3 for circulating electrophoretic fluid 1, and a nozzle 41 is provided in the tank body 2. pipe 4, the spray pipe 4 communicates with the pipeline pipeline 3, and the pressurized unit (the unit includes A unit 31 and B unit 32) is connected in series on the pipeline pipeline 3, and in the Nozzles 41 are added in the slow-flow area or stagnant-flow area in the tank body 2 , and nozzles 41 can also be added in the slow-flow area or stagnant-flow area of the pipeline pipeline 3 . The slow flow area 11 is the corner position of the tank body and the inlet of the nozzle. The liquid flow velocity in the above positions is very slow, resultin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com